5318312

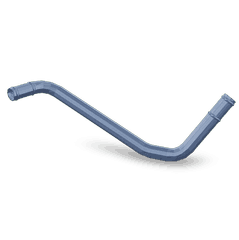

Compressor Water Inlet Tube

Cummins®

IN STOCK

10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Compressor Water Inlet Tube (5318312) by Cummins is a component designed to facilitate the efficient operation of heavy-duty trucks. This part is integral to the engine cooling system, ensuring that the compressor remains at optimal temperatures during operation. Its role is significant in maintaining the overall performance and longevity of the truck’s engine 1.

Basic Concepts

Compressor water inlet tubes are fundamental to the engine cooling system, directing coolant into the compressor to manage its temperature. These tubes interact with various engine components, including the radiator, thermostat, and water pump, to maintain a consistent coolant flow. Understanding these interactions is key to grasping the tube’s function within the cooling system 2.

Purpose and Function

The Compressor Water Inlet Tube (5318312) plays a role in the operation of a truck by channeling coolant into the compressor. This process helps in dissipating heat generated during compression, thereby contributing to engine cooling and performance. Effective cooling is vital for preventing overheating, which can lead to engine damage and reduced efficiency 3.

Key Features

The Compressor Water Inlet Tube (5318312) is constructed from durable materials, ensuring it can withstand the high pressures and temperatures within the engine cooling system. Its design includes precise fittings and connections that facilitate a secure and leak-free installation. These features contribute to the tube’s performance and durability, making it a reliable component in heavy-duty applications 4.

Benefits

Using the Compressor Water Inlet Tube (5318312) is associated with several benefits. It contributes to improved engine efficiency by ensuring the compressor operates within optimal temperature ranges. Enhanced cooling performance leads to better overall engine reliability, reducing the risk of overheating and associated damages. Additionally, the tube’s durable construction and design elements support long-term use without frequent replacements 5.

Installation and Compatibility

Proper installation of the Compressor Water Inlet Tube (5318312) is crucial for ensuring its effectiveness. It is important to follow manufacturer guidelines to ensure compatibility with various truck models and engine types. Specific requirements may include checking for correct fitment and ensuring all connections are secure to prevent leaks 6.

Maintenance and Troubleshooting

To ensure optimal performance of the Compressor Water Inlet Tube (5318312), regular maintenance is recommended. This includes checking for signs of wear or damage, ensuring connections remain tight, and verifying that coolant levels are adequate. Common troubleshooting techniques involve inspecting for leaks, assessing the condition of the tube, and addressing any issues promptly to maintain engine efficiency and reliability 7.

Cummins Overview

Cummins is a well-established manufacturer with a strong reputation in the automotive and heavy-duty truck industry. Known for its commitment to producing high-quality components, Cummins has a history of innovation and excellence. The company’s dedication to quality and performance is evident in its wide range of products, including the Compressor Water Inlet Tube (5318312) 8.

Compatibility of Compressor Water Inlet Tube (Part 5318312) with Cummins Engines

The Compressor Water Inlet Tube, identified by part number 5318312 and manufactured by Cummins, is a critical component in the cooling system of certain Cummins engines. This part is designed to fit seamlessly with specific engine models, ensuring efficient operation and longevity of the engine.

ISB6.7 CM2350 B101 and QSB6.7 CM2250

The Compressor Water Inlet Tube (5318312) is compatible with the ISB6.7 CM2350 B101 and QSB6.7 CM2250 engines. These engines are part of Cummins’ lineup, known for their robust performance and reliability. The part is engineered to integrate smoothly with the cooling systems of these engines, facilitating the flow of coolant and maintaining optimal operating temperatures.

QSB6.7 CM2350 B105

Similarly, the Compressor Water Inlet Tube (5318312) is also compatible with the QSB6.7 CM2350 B105 engine. This engine shares many design elements with the ISB6.7 CM2350 B101 and QSB6.7 CM2250, ensuring that the part fits perfectly and functions as intended. The design of the tube allows for efficient coolant flow, which is crucial for the engine’s performance and durability.

By ensuring that the Compressor Water Inlet Tube (5318312) is correctly installed in these engines, users can maintain the integrity of the cooling system, thereby enhancing the overall performance and lifespan of the engine 9.

Role of Part 5318312 Compressor Water Inlet Tube in Engine Systems

The part 5318312 Compressor Water Inlet Tube is an integral component in the efficient operation of engine systems, particularly in those that require precise coolant management. This tube is designed to facilitate the smooth and controlled entry of coolant into the compressor, ensuring optimal performance and longevity of the engine.

Interaction with Plumbing Systems

In the context of engine plumbing, the 5318312 Compressor Water Inlet Tube serves as a vital conduit. It connects to the main coolant lines, allowing for a steady flow of coolant to be directed towards the compressor. This connection is essential for maintaining the correct coolant levels within the system, which is necessary for effective heat dissipation and prevention of overheating 10.

Integration with Compressor Coolant Systems

When it comes to compressor coolant systems, the role of the 5318312 Compressor Water Inlet Tube becomes even more significant. The tube ensures that the compressor receives a consistent supply of coolant, which is imperative for its efficient operation. The coolant helps in reducing the temperature of the compressed air, thereby enhancing the overall efficiency of the compressor. Additionally, it aids in preventing the buildup of heat, which could otherwise lead to component wear and reduced performance.

The tube’s design allows for minimal resistance to coolant flow, which is crucial for maintaining the pressure and temperature balance within the compressor. This balance is essential for the compressor to function within its specified parameters, ensuring reliable and consistent performance 11.

Conclusion

In summary, the 5318312 Compressor Water Inlet Tube plays a key role in the plumbing and compressor coolant systems by ensuring a steady and controlled supply of coolant. This contributes to the efficient operation and longevity of the engine components. Proper installation, maintenance, and understanding of its function are crucial for maximizing the benefits of this Cummins part.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩ -

Modern Diesel Technology: Heavy Equipment Systems, Robert Huzij, Angelo Spano, Sean Bennett, Cengage Learning, 2019.

↩ -

Auto Repair for Dummies: 2nd Edition, Deanna Sclar, For Dummies, 2008.

↩ -

Fuel Consumption and Consumption Optimization, Second Edition, Michael Hilgers, Springer Nature, 2023.

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩ -

Modern Diesel Technology: Heavy Equipment Systems, Robert Huzij, Angelo Spano, Sean Bennett, Cengage Learning, 2019.

↩ -

Auto Repair for Dummies: 2nd Edition, Deanna Sclar, For Dummies, 2008.

↩ -

Fuel Consumption and Consumption Optimization, Second Edition, Michael Hilgers, Springer Nature, 2023.

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩ -

Modern Diesel Technology: Heavy Equipment Systems, Robert Huzij, Angelo Spano, Sean Bennett, Cengage Learning, 2019.

↩ -

Auto Repair for Dummies: 2nd Edition, Deanna Sclar, For Dummies, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.