This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

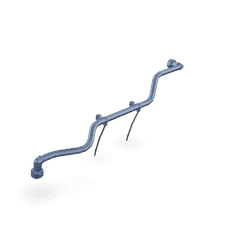

The Compressor Water Inlet Tube, identified by part number 5319165, is a component manufactured by Cummins, a leading provider of diesel engines and related technologies. This tube is integral to the cooling system of heavy-duty truck engines, ensuring optimal performance and longevity of the engine components.

Function and Operation

The Compressor Water Inlet Tube facilitates the flow of coolant into the compressor section of the engine. It plays a role in the engine cooling system by directing coolant to areas where heat buildup is most significant, thus maintaining the engine’s operating temperature within specified limits. The tube interacts with the engine’s water pump, thermostat, and various coolant passages to ensure efficient heat dissipation 1.

Purpose of the Compressor Water Inlet Tube

The specific role of the Compressor Water Inlet Tube in a truck’s operation is to enhance engine efficiency and performance by ensuring that the compressor remains at an optimal temperature. This is achieved through the regulated flow of coolant, which prevents overheating and potential damage to the compressor and other engine components 2.

Key Features

The Compressor Water Inlet Tube is constructed from durable materials designed to withstand the high pressures and temperatures of the engine cooling system. Its design includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, the tube may feature reinforced sections to handle the dynamic forces within the engine compartment 3.

Benefits

The advantages provided by the Compressor Water Inlet Tube include improved engine cooling, which contributes to the overall reliability and performance of the engine. Its robust construction increases durability, reducing the frequency of replacements and maintenance. For fleet operators, this can translate into cost savings over the vehicle’s lifespan 4.

Installation and Integration

Proper installation of the Compressor Water Inlet Tube requires attention to detail to ensure compatibility with the engine system. Prerequisites include a clean and undamaged installation site, and the necessary tools may include wrenches, sealant, and a torque wrench. Following the manufacturer’s guidelines is crucial to ensure the tube is correctly positioned and secured, allowing for efficient coolant flow and engine operation.

Troubleshooting and Maintenance

Common issues associated with the Compressor Water Inlet Tube may include leaks, blockages, or damage from corrosion. Diagnostic tips involve checking for coolant leaks, ensuring there are no obstructions in the coolant flow, and inspecting the tube for signs of wear or damage. Regular maintenance practices, such as flushing the cooling system and replacing the tube as part of a scheduled maintenance program, can prolong its lifespan and ensure optimal performance.

Performance Impact

The Compressor Water Inlet Tube affects overall engine performance by contributing to efficient heat management. This can lead to improved fuel efficiency, as the engine operates more effectively within its designed temperature range. Additionally, proper cooling can reduce emissions by ensuring the engine runs cleaner and more efficiently.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The development of components like the Compressor Water Inlet Tube reflects Cummins’ commitment to enhancing engine performance and durability.

Cummins Compressor Water Inlet Tube 5319165 Compatibility

The Cummins Compressor Water Inlet Tube, part number 5319165, is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This component is integral to the cooling system of the engines, facilitating the flow of water to the compressor.

QSL9 Engines

The QSL9 series engines benefit from the precise engineering of the 5319165 Compressor Water Inlet Tube. This part ensures that the cooling system operates efficiently, maintaining the ideal temperature for the engine’s compressor. The fitment is precise, allowing for a secure connection that minimizes the risk of leaks and enhances the overall durability of the engine.

CM2350 Engines

For the CM2350 engines, the 5319165 Compressor Water Inlet Tube is engineered to meet the specific demands of these high-performance engines. The design ensures that the water flow is consistent and reliable, contributing to the engine’s ability to handle heavy loads and maintain peak performance. The tube’s compatibility with the CM2350 series underscores Cummins’ commitment to quality and precision in engine components.

L102 Engines

The L102 engines also integrate the 5319165 Compressor Water Inlet Tube with ease. This part is crucial for the cooling system’s efficiency, ensuring that the compressor operates within its optimal temperature range. The fitment process is straightforward, allowing for quick and reliable installation that enhances the engine’s longevity and performance.

Each of these engines, whether part of the QSL9, CM2350, or L102 series, relies on the 5319165 Compressor Water Inlet Tube to maintain its cooling system’s integrity. Cummins’ engineering ensures that this part fits perfectly, providing a reliable solution for engine cooling needs.

Role of Part 5319165 Compressor Water Inlet Tube in Engine Systems

The part 5319165 Compressor Water Inlet Tube is an essential component in the arrangement of the engine’s cooling system, specifically designed to facilitate the efficient flow of coolant to the compressor.

In the context of the compressor coolant system, this tube serves as a direct pathway for coolant from the engine’s cooling circuit to the compressor. Its primary function is to ensure a consistent and reliable supply of coolant, which is vital for maintaining optimal operating temperatures of the compressor.

The tube interfaces with the compressor’s inlet port, allowing coolant to enter the compressor housing. Once inside, the coolant circulates around the compressor’s internal components, absorbing excess heat generated during operation. This heat absorption is key to preventing overheating, which can lead to reduced efficiency and potential damage to the compressor.

Additionally, the design of the Compressor Water Inlet Tube allows for minimal restriction to coolant flow, ensuring that the compressor receives an adequate supply under all operating conditions. This is particularly important during high-load scenarios where the demand for cooling is greatest.

The integration of the Compressor Water Inlet Tube within the engine system underscores the importance of precise engineering in maintaining the balance between performance and reliability. Its role in the coolant arrangement is fundamental to the overall health and longevity of the compressor and, by extension, the engine system as a whole.

Conclusion

The Compressor Water Inlet Tube, part number 5319165, is a critical component in the cooling system of heavy-duty truck engines. Its role in facilitating efficient coolant flow to the compressor ensures optimal engine performance and longevity. Proper installation, maintenance, and understanding of its function are essential for maximizing the benefits of this Cummins part.

-

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Huzij, Robert, Angelo Spano, and Sean Bennett. Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning, 2014.

↩ -

Lakshminarayanan, P. A., and Nagaraj S. Nayak. Critical Component Wear in Heavy Duty Engines. John Wiley & Sons, 2011.

↩ -

Caines, Arthur J, Roger F Haycock, and John E Hillier. Automotive Lubricants Reference Book. SAE International, 2004.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.