This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

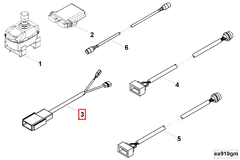

The Cummins 5320016 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as an essential element in the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This part ensures that electrical signals and power are efficiently distributed throughout the truck, contributing to the overall functionality and performance of the vehicle.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals to various components within a vehicle. It typically includes insulated wires bundled together, connectors for joining wires, and protective housing to shield the wires from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured and organized method for electrical distribution, reducing the risk of short circuits and ensuring reliable operation of electrical components 1.

Purpose of the 5320016 Wiring Harness

This Cummins part is specifically designed to integrate with the electrical system of commercial trucks. It connects various electrical components, such as sensors, lights, and control units, to the truck’s power source. This harness plays a role in ensuring that electrical signals are accurately transmitted and that power is efficiently distributed to all necessary components. Its design allows for seamless integration with other systems within the truck, enhancing overall electrical system performance 2.

Key Features

The 5320016 Wiring Harness is characterized by several key features that enhance its performance and durability. These include a robust design that withstands the harsh conditions often encountered in commercial truck operations, high-quality materials that ensure longevity and reliability, and precise engineering that guarantees accurate electrical connections. Additionally, the harness may feature protective coatings and shielding to further protect against environmental factors and physical damage 3.

Benefits

This part offers several advantages in truck operations. It contributes to improved efficiency by ensuring that electrical power and signals are reliably transmitted throughout the vehicle. This reliability enhances the overall performance and safety of the truck, as all electrical components operate as intended. Furthermore, the harness’s durable construction and protective features help to extend its lifespan, reducing the need for frequent replacements and maintenance 4.

Installation Process

Installing the 5320016 Wiring Harness requires careful attention to detail and adherence to safety protocols. The process involves disconnecting the battery to prevent electrical shocks, routing the harness through the truck’s designated pathways, connecting it to the appropriate electrical components, and securing it in place. Tools such as wire strippers, crimping tools, and electrical tape may be required. Safety precautions include wearing insulated gloves and ensuring that all connections are secure and properly insulated to prevent short circuits.

Troubleshooting Common Issues

Common issues with the 5320016 Wiring Harness may include loose connections, damaged wires, or faulty connectors. Troubleshooting steps involve visually inspecting the harness for any signs of damage, ensuring that all connections are secure, and using a multimeter to test for continuity and proper electrical flow. If a fault is detected, the affected section of the harness may need to be repaired or replaced to restore proper function.

Maintenance Tips

Regular maintenance of the 5320016 Wiring Harness is important to ensure its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, ensuring that all connections remain secure, and cleaning the harness to remove any dirt or debris that could interfere with electrical conductivity. Additionally, protecting the harness from physical damage and environmental factors, such as moisture and extreme temperatures, will help to maintain its integrity.

Safety Considerations

When working with the 5320016 Wiring Harness, it is important to observe electrical safety practices. This includes disconnecting the battery before beginning any work to prevent electrical shocks, using insulated tools to avoid short circuits, and wearing appropriate personal protective equipment, such as insulated gloves and safety glasses. Handling the harness with care and ensuring that all connections are properly insulated will help to prevent accidents and ensure safe operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable, and efficient power solutions. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial vehicle applications. Cummins’ commitment to innovation and customer satisfaction has solidified its position as a trusted name in the industry.

Cummins Engine Wiring Harness 5320016 Compatibility

The Cummins Wiring Harness part number 5320016 is designed to integrate seamlessly with a variety of Cummins engines, ensuring reliable electrical connectivity and system functionality. This wiring harness is compatible with the following engines:

- QSB6.7 M CM2250

- QSC8.3 CM850 (CM2850)

- QSM11 CM570

For the QSB6.7 M CM2250 and QSC8.3 CM850 (CM2850), the wiring harness 5320016 is engineered to connect the engine’s electrical components, ensuring that power is distributed efficiently and safely. This is crucial for maintaining optimal engine performance and preventing electrical failures.

In the case of the QSM11 CM570, the wiring harness 5320016 is tailored to handle the specific electrical demands of this engine model. It ensures that all electrical systems are properly connected and that the engine can operate without interruptions.

The design of the wiring harness 5320016 is such that it can be easily installed and integrated into the engine’s existing electrical architecture. This compatibility across different engine models highlights Cummins’ commitment to providing a standardized and reliable solution for their engine lineup.

Role of Part 5320016 Wiring Harness in Engine Systems

The 5320016 Wiring Harness is an integral component in the electrical systems of marine engines, facilitating seamless communication and power distribution among various components.

Integration with Accessories

The wiring harness efficiently connects to multiple accessories, ensuring they receive the necessary power and signals to operate correctly. This includes but is not limited to, lighting systems, navigation equipment, and entertainment systems. By providing a structured pathway for electrical signals, the harness minimizes the risk of short circuits and ensures consistent performance of these accessories.

Connection to Alternate Helm Electrical Systems

In vessels equipped with alternate helm stations, the 5320016 Wiring Harness plays a significant role. It ensures that the alternate helm has access to all necessary electrical connections, allowing for the operation of engine controls, navigation systems, and communication devices from a secondary location. This redundancy is essential for safety and operational flexibility, especially in larger vessels where multiple control points are beneficial.

Main Helm Electrical Integration

At the main helm, the wiring harness is the backbone of the electrical system. It connects the primary control panel to the engine, allowing for the transmission of commands and feedback. This includes throttle control, gear shifting, and monitoring engine parameters such as temperature and oil pressure. The harness ensures that all electrical components at the main helm are powered and can communicate effectively with the engine and other systems.

Harnessing Alternate Station Capabilities

For vessels with alternate stations, the 5320016 Wiring Harness ensures that these stations are fully functional. It provides the necessary connections for engine controls, allowing operators to manage the vessel from different locations. This is particularly useful in larger vessels where multiple operators may need to control the engine and navigate the vessel simultaneously.

Conclusion

In summary, the 5320016 Wiring Harness is a fundamental component in the electrical architecture of marine engines, ensuring reliable and efficient operation of accessories, alternate helm systems, main helm electrical systems, and alternate stations. Its robust design, compatibility with various Cummins engines, and integration capabilities make it an essential part of the electrical system in commercial trucks and marine vessels.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩ -

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩ -

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.