This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

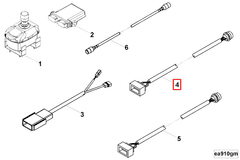

Wiring harnesses are fundamental components in the electrical systems of vehicles, including commercial trucks. They consist of a collection of wires, connectors, and terminals that are bundled together to facilitate the transmission of electrical signals and power between various components of the vehicle. In commercial trucks, wiring harnesses play a significant role by ensuring that all electrical systems, from lighting to engine controls, operate cohesively and efficiently. They simplify the complex network of wires that would otherwise be required to connect each component individually, thereby reducing the risk of electrical faults and improving the overall reliability of the vehicle’s electrical system 1.

Purpose of the 5321011 Wiring Harness

The 5321011 Wiring Harness by Cummins is designed to serve a specific function within the electrical system of a truck. It integrates various electrical components, ensuring that they receive the necessary power and signals to operate correctly. This Cummins part is engineered to support the demanding conditions encountered in heavy-duty applications, providing a reliable connection that contributes to the efficient and dependable performance of the truck’s electrical system.

Key Features of the 5321011 Wiring Harness

The 5321011 Wiring Harness is characterized by several key features that enhance its functionality and durability. Its design incorporates high-quality materials that are resistant to the harsh environments typically faced by commercial trucks. The harness is constructed with robust insulation and durable connectors, which help to protect against physical damage and environmental factors such as moisture and extreme temperatures. Additionally, the harness is engineered to be flexible yet sturdy, allowing it to withstand the vibrations and movements inherent in truck operations while maintaining secure connections.

Benefits of Using the 5321011 Wiring Harness

Utilizing the 5321011 Wiring Harness offers several advantages. It contributes to improved electrical efficiency by providing a streamlined path for electrical signals and power, which can help reduce energy loss. The design of the harness also minimizes the risk of short circuits, enhancing the safety and reliability of the truck’s electrical system. Furthermore, the durability and quality of the materials used in the harness ensure that it can withstand the rigors of heavy-duty use, leading to a longer service life and reduced need for repairs.

Installation Considerations

When installing the 5321011 Wiring Harness, it is important to follow guidelines and best practices to ensure proper integration with the truck’s electrical system. Preparatory steps may include ensuring that the truck’s electrical system is powered down to prevent any risk of electrical shock or damage. The use of appropriate tools is crucial for making secure connections and avoiding damage to the harness or the components it connects. Common pitfalls during installation include improper routing of the harness, which can lead to abrasion or damage, and insufficient securing of connections, which may result in intermittent electrical issues.

Troubleshooting Common Issues

Identifying and resolving common problems associated with wiring harnesses can help maintain the efficiency and reliability of a truck’s electrical system. Diagnostic tips include checking for signs of wear or damage on the harness and connectors, as these can indicate potential issues. Potential causes of electrical faults may include loose connections, damaged insulation, or exposure to moisture. Recommended solutions involve repairing or replacing damaged sections of the harness, ensuring all connections are secure, and protecting the harness from environmental factors.

Maintenance Tips

To ensure the longevity and optimal performance of the 5321011 Wiring Harness, regular maintenance is recommended. This includes inspecting the harness for signs of wear, damage, or corrosion, and cleaning it to remove any dirt or debris that could affect its performance. It is also important to check that all connections are secure and that there are no exposed wires. If any issues are detected during maintenance, it may be necessary to consider repairs or replacements to prevent more significant problems from developing.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry, particularly in the realm of diesel engines and related technologies. The company is committed to innovation, quality, and customer satisfaction, providing solutions that meet the demanding needs of commercial and industrial applications.

Cummins Engine Wiring Harness 5321011 Compatibility

The Cummins Wiring Harness part number 5321011 is designed to integrate seamlessly with a range of Cummins engines, ensuring reliable electrical connectivity and system functionality. This wiring harness is compatible with the following engines:

- QSB6.7 M CM2250

- QSC8.3 CM850 (CM2850)

- QSM11 CM570

For the QSB6.7 M CM2250 and QSC8.3 CM850 (CM2850), the wiring harness is engineered to handle the specific electrical demands of these engines, providing robust connections to various engine components and systems. This ensures that the electrical systems operate efficiently, contributing to the overall performance and reliability of the engine.

In the case of the QSM11 CM570, the wiring harness is tailored to meet the unique electrical requirements of this engine model. It ensures that all electrical components are properly connected, facilitating smooth operation and reducing the risk of electrical failures.

The design of the wiring harness allows for easy installation and maintenance, making it a reliable choice for technicians and operators who need to ensure that their engines are running at peak efficiency. The harness is constructed with high-quality materials to withstand the rigors of engine operation, ensuring longevity and durability.

Role of Part 5321011 Wiring Harness in Engine Systems

The 5321011 Wiring Harness is an integral component in the electrical architecture of engine systems, facilitating seamless communication and power distribution between various elements.

Integration with Accessories

When interfacing with accessories, the 5321011 Wiring Harness ensures that power is efficiently routed from the engine’s power source to components such as lights, sensors, and auxiliary systems. This harness is designed to handle multiple connections, reducing the risk of electrical interference and ensuring that each accessory receives a stable and consistent power supply. It also plays a role in data transmission, allowing accessories to communicate with the engine’s control unit, thereby enabling features like diagnostic reporting and performance monitoring.

Connection to Main Helm Electrical System

In the context of the main helm electrical system, the 5321011 Wiring Harness serves as the backbone for the electrical network. It connects the helm’s control panel to the engine’s electrical components, ensuring that commands from the helm are accurately transmitted to the engine. This includes throttle control, ignition signals, and other operational commands. The harness also facilitates feedback from the engine to the helm, providing real-time data on engine performance, status, and any potential issues. This bidirectional communication is essential for maintaining optimal engine operation and ensuring safety.

Conclusion

The 5321011 Wiring Harness by Cummins is a critical component in the electrical systems of commercial trucks, designed to ensure reliable and efficient operation of various electrical components. Its high-quality construction, compatibility with specific Cummins engines, and robust features make it a valuable asset for maintaining the performance and reliability of heavy-duty vehicles. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, ensuring long-term durability and minimal downtime.

-

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.