This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

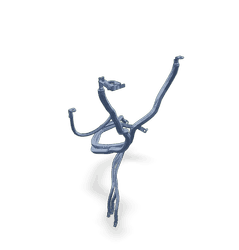

The 5331712 Wiring Harness, manufactured by Cummins, is a vital component in the electrical system of commercial trucks. Cummins, a well-established name in the commercial truck industry, produces this wiring harness to ensure reliable and efficient electrical connections within the vehicle. This harness plays a role in the overall operation and performance of commercial trucks, contributing to their functionality and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and terminals that transmit electrical power and signals between various components of a vehicle. It consists of insulated wires bundled together and secured with ties or conduits. The primary function of a wiring harness is to organize and protect the electrical connections, ensuring efficient and safe operation of the vehicle’s electrical system. Within a commercial truck, the wiring harness facilitates communication and power distribution to critical systems such as the engine, transmission, lighting, and various sensors 1.

Purpose of the 5331712 Wiring Harness

This Cummins part is designed to play a specific role in the operation of a commercial truck. It provides the necessary electrical connections for various components, ensuring seamless integration with the truck’s systems. This harness is engineered to handle the demanding conditions of commercial truck operations, offering reliable performance and durability. Its design allows for efficient power distribution and signal transmission, contributing to the overall functionality of the truck.

Key Features

The 5331712 Wiring Harness boasts several key features that enhance its performance and durability. It is constructed using high-quality materials that are resistant to wear, corrosion, and environmental factors. The design of the harness includes robust connectors and terminals that ensure secure and reliable connections. Additionally, the harness is engineered to withstand the vibrations and harsh conditions typical of commercial truck operations, providing long-lasting performance 2.

Benefits

The advantages of using the 5331712 Wiring Harness in commercial truck operations are numerous. It offers improved efficiency by ensuring reliable electrical connections, which can lead to better overall performance of the truck. The harness contributes to the reliability of the electrical system, reducing the likelihood of failures and downtime. Furthermore, by providing stable and secure connections, it enhances the safety of the truck’s electrical operations, protecting both the vehicle and its occupants 3.

Installation Considerations

Proper installation of this Cummins part is crucial for ensuring its effective performance within the truck’s electrical system. It is important to follow guidelines and best practices during installation to achieve a proper setup. This includes ensuring that all connections are secure and that the harness is routed correctly to avoid damage from moving parts or heat sources. Careful attention to these details will help integrate the harness seamlessly into the truck’s electrical system.

Troubleshooting and Maintenance

To maintain the longevity and optimal performance of the 5331712 Wiring Harness, regular troubleshooting and maintenance are recommended. Common issues may include loose connections, damaged wires, or corroded terminals. Inspecting the harness periodically for signs of wear or damage can help identify potential problems early. Maintenance tips include keeping the harness clean and dry, ensuring that connections remain secure, and protecting the harness from physical damage.

Compatibility and Applications

This part is designed for use in specific types of commercial trucks and engines. It is important to verify compatibility with the truck model and engine series to ensure proper fit and function. This harness is engineered to meet the demands of commercial truck operations, providing reliable electrical connections for a variety of applications.

Safety and Compliance

The 5331712 Wiring Harness adheres to safety standards and regulatory compliance requirements for commercial vehicle operation. It is designed to meet industry specifications, ensuring that it provides safe and reliable electrical connections. Compliance with these standards helps ensure the harness operates within the parameters set for commercial truck safety and performance.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products and strong reputation. With a history of innovation and quality, Cummins produces a variety of components and systems designed to enhance the performance and reliability of commercial trucks. The company’s commitment to excellence is reflected in its products, including the 5331712 Wiring Harness, which is engineered to meet the high standards of the commercial truck industry.

Wiring Harness 5331712 by Cummins

The Wiring Harness 5331712 by Cummins is a critical component designed to ensure seamless electrical connectivity within various engine systems. This part is engineered to fit into multiple engine configurations, providing a reliable and efficient means of transmitting electrical signals.

ISB (Chrysler)

For the ISB engines, the Wiring Harness 5331712 is meticulously designed to interface with the engine’s electrical architecture. It ensures that all necessary components, such as sensors, actuators, and control modules, are properly connected. This harness is crucial for maintaining optimal engine performance and reliability, as it facilitates the flow of electrical power and data throughout the engine system.

The harness is constructed to withstand the harsh conditions typically encountered in engine environments, including high temperatures, vibrations, and exposure to various elements. Its robust design ensures longevity and consistent performance, making it an essential part for ISB engines.

By integrating seamlessly with the engine’s electrical framework, the Wiring Harness 5331712 by Cummins plays a pivotal role in the overall functionality and efficiency of the ISB engines.

Role of Part 5331712 Wiring Harness in Engine Systems

The Part 5331712 Wiring Harness is a component that facilitates the electrical connections within the engine system. It ensures that power and signals are accurately transmitted between various components, enhancing the overall functionality and reliability of the engine.

Integration with the Motor

The wiring harness plays a role in connecting the motor to the power source and control units. It provides the necessary electrical pathways for the motor to receive power, enabling it to operate efficiently. Additionally, the harness includes connections for sensors that monitor the motor’s performance, allowing for real-time data collection and feedback. This ensures that the motor operates within optimal parameters, reducing the risk of overheating or mechanical failure.

Connection to the Starting System

In the starting system, the wiring harness is responsible for linking the starter motor to the battery and ignition system. When the ignition is engaged, the harness transmits the electrical current required to activate the starter motor, which in turn cranks the engine. The harness also incorporates safety features, such as fuses and relays, to protect the electrical system from overloads and short circuits. This ensures that the starting process is both reliable and safe, contributing to the engine’s overall performance and longevity.

Conclusion

The 5331712 Wiring Harness by Cummins is a critical component in the electrical systems of commercial trucks, ensuring reliable and efficient operation. Its robust design, compatibility with various engine configurations, and adherence to safety standards make it an essential part for maintaining the performance and safety of commercial vehicles.

-

Haoran Hu, Rudy Smaling, and Simon Baseley, Heavy-Duty Wheeled Vehicles (SAE International, 2014).

↩ -

Paul Dempsey, Troubleshooting and Repairing Diesel Engines, 5th Edition (McGraw-Hill, 2018).

↩ -

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.