This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5335465 Sacrificial Anode is a specialized component designed to protect metal parts from corrosion in commercial truck systems. Its role is significant in maintaining the integrity and longevity of truck components, ensuring reliable operation and reducing maintenance costs.

Basic Concepts of Sacrificial Anodes

Sacrificial anodes function by corroding in place of the metal components they are designed to protect. This process, known as cathodic protection, involves the anode material being more electrochemically active than the protected metal. As a result, the anode corrodes first, thereby preserving the integrity of the surrounding metal parts 1.

Purpose of the Cummins 5335465 Sacrificial Anode

The Cummins 5335465 Sacrificial Anode is specifically engineered to protect various metal components within commercial truck systems from corrosion. It is commonly applied in cooling systems, fuel tanks, and other areas where metal parts are exposed to corrosive environments. By doing so, it helps maintain the efficiency and reliability of these systems.

Key Features

The Cummins 5335465 Sacrificial Anode is composed of a high-quality magnesium alloy, which provides superior corrosion protection. Its design ensures easy installation and effective performance. Unique characteristics include a robust construction that withstands harsh operating conditions and a shape that maximizes surface area for enhanced protection.

Benefits of Using the Cummins 5335465 Sacrificial Anode

Utilizing the Cummins 5335465 Sacrificial Anode offers several benefits. It extends the life of metal components by preventing corrosion, reduces maintenance costs by minimizing the need for repairs or replacements, and improves overall truck reliability. This results in fewer downtimes and more consistent performance.

Installation Process

Proper installation of the Cummins 5335465 Sacrificial Anode involves several steps. First, ensure the area where the anode will be installed is clean and free of debris. Use the appropriate tools to secure the anode in place, following the manufacturer’s guidelines. It is important to check for proper electrical connection and ensure the anode is fully submerged in the relevant fluid (e.g., coolant or fuel) for effective protection.

Maintenance and Inspection

Regular maintenance and inspection of the Cummins 5335465 Sacrificial Anode are crucial for its continued effectiveness. Inspect the anode periodically for signs of wear or significant corrosion. Recommended inspection intervals vary but generally align with routine maintenance schedules. If the anode shows substantial degradation, it should be replaced to ensure ongoing protection.

Troubleshooting Common Issues

Common issues with the Cummins 5335465 Sacrificial Anode may include inadequate protection due to improper installation or environmental factors accelerating corrosion. Symptoms might include increased corrosion on protected components. To address these issues, verify the anode’s installation, ensure it is correctly positioned and electrically connected, and consider environmental conditions that may affect its performance.

Environmental and Safety Considerations

The use and disposal of the Cummins 5335465 Sacrificial Anode should adhere to environmental regulations and safety standards. Proper disposal methods for spent anodes should be followed to minimize environmental impact. Additionally, handling the anode during installation and maintenance should be done with appropriate safety measures to protect personnel from potential hazards.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and a broad product range, Cummins is renowned for its commitment to quality and reliability in the commercial truck industry. The company’s reputation is built on delivering high-performance solutions that meet the demanding needs of commercial transportation 2.

Sacrificial Anode (Part 5335465) in Cummins Engines

The Cummins part 5335465, a Sacrificial Anode, is a critical component in the maintenance and longevity of several Cummins engine models. This part is designed to protect the engine’s cooling system from corrosion by sacrificing itself in place of the engine’s metal components.

Application in Specific Engines

QSB6.7 M CM2250 and QSC8.3 CM850 (CM2850)

The QSB6.7 M CM2250 and QSC8.3 CM850 (CM2850) engines both benefit from the use of the sacrificial anode. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The sacrificial anode ensures that the cooling system remains free from corrosive elements, which can otherwise lead to costly repairs and downtime.

QSM11 CM570

Similarly, the QSM11 CM570 engine incorporates the sacrificial anode to maintain the integrity of its cooling system. This engine is typically utilized in applications where durability and efficiency are paramount. The anode’s role in preventing corrosion helps to extend the engine’s lifespan and maintain its operational efficiency.

Importance of the Sacrificial Anode

The sacrificial anode is an essential part of the engine’s maintenance regimen. By regularly inspecting and replacing the anode as needed, engine operators can prevent the onset of corrosion, which can compromise the engine’s performance and lead to more severe damage over time. This proactive approach to maintenance ensures that the engine continues to operate at peak efficiency, reducing the likelihood of unexpected failures 3.

Understanding the Role of Part 5335465 Sacrificial Anode in Engine Systems

When it comes to maintaining the integrity of marine engine systems, the integration of part 5335465 Sacrificial Anode is instrumental. This component is specifically designed to protect various metallic parts from corrosion, ensuring the longevity and efficiency of the engine system.

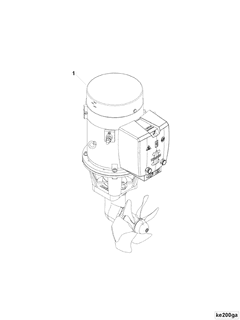

Integration with Thrusters

In thruster systems, the Sacrificial Anode plays a significant role in safeguarding the metallic components from the corrosive effects of seawater. The thruster, which is essential for maneuvering the vessel, comprises several metallic parts that are susceptible to corrosion. The anode, when installed correctly, attracts corrosive elements away from these parts, thereby extending the operational life of the thruster.

Protection of Bow and Stern Thrusters

Both bow and stern thrusters are critical for the precise control of a vessel’s direction. These thrusters are often exposed to harsh marine environments, making them particularly vulnerable to corrosion. The Sacrificial Anode, when fitted to these thrusters, ensures that the metallic components, such as the propeller and housing, remain protected. This protection is vital for maintaining the thruster’s performance and reliability over time.

Enhancing Stern Thruster Drive Longevity

The stern thruster drive, which includes the motor, gearbox, and propeller shaft, is another area where the Sacrificial Anode proves beneficial. By preventing corrosion on these components, the anode helps in maintaining the structural integrity and functional efficiency of the stern thruster drive. This, in turn, contributes to the overall stability and control of the vessel.

Conclusion

In summary, the Sacrificial Anode is a key component in the protection of various engine systems, particularly those involving thrusters. Its role in attracting corrosive elements away from metallic parts ensures that these systems remain efficient and reliable, even in challenging marine environments. Regular inspection and maintenance of the anode are crucial to ensure its effectiveness and the continued performance of the engine system.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.