This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

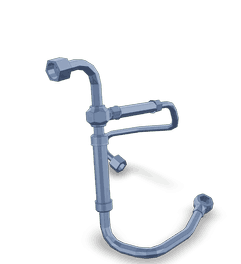

Understanding the Cummins 5336199 Tur Coolant Drain Tube

Introduction to Cummins 5336199 Tur Coolant Drain Tube

Cummins has long been a cornerstone in the commercial truck parts industry, renowned for its commitment to innovation and reliability. With a rich history of manufacturing high-quality engine components, Cummins continues to set industry standards. One such critical component is the Cummins 5336199 Tur Coolant Drain Tube, a vital part in the engine cooling system that ensures optimal engine performance and longevity 3.

The Tur Coolant Drain Tube is designed to facilitate the efficient drainage of coolant from the engine block. Proper coolant management is essential for maintaining engine temperature, preventing overheating, and ensuring the engine operates within its optimal range 4.

How the Cummins 5336199 Tur Coolant Drain Tube Works

The Tur Coolant Drain Tube plays a crucial role in the engine cooling system by allowing coolant to be drained from the engine block during maintenance or when the coolant needs to be replaced. This process is vital for removing old or contaminated coolant, which can otherwise lead to engine inefficiencies and potential damage 1.

Constructed from high-quality materials, the Tur Coolant Drain Tube is designed to withstand the harsh conditions within an engine environment. Its robust design ensures durability and efficiency, making it a reliable component in the cooling system 2.

Purpose and Role in Truck Operations

The Tur Coolant Drain Tube is instrumental in maintaining optimal engine temperature, which is critical for engine performance and longevity. By ensuring efficient coolant drainage, it helps prevent engine overheating, a common issue that can lead to severe engine damage 3.

Regular inspection and maintenance of the Tur Coolant Drain Tube are essential for preventive maintenance. Proper coolant drainage not only enhances engine efficiency but also extends the engine’s lifespan by preventing overheating and associated damages 4.

Troubleshooting and Maintenance

Identifying signs of a malfunctioning Tur Coolant Drain Tube is crucial for maintaining engine health. Common issues include coolant leaks, reduced coolant levels, and engine overheating, which can indicate a clogged or damaged drain tube 1.

To maintain the Tur Coolant Drain Tube, mechanics should conduct regular inspections and cleanings. A step-by-step guide involves draining the coolant, inspecting the tube for any signs of wear or damage, and cleaning it thoroughly. If the tube is damaged, it should be replaced promptly to ensure continued engine efficiency 2.

Cummins’ Commitment to Quality and Innovation

Cummins employs rigorous quality assurance processes to manufacture the Tur Coolant Drain Tube, ensuring it meets high industry standards. The company adheres to various certifications and industry benchmarks, reinforcing its commitment to quality 3.

Innovation is at the heart of Cummins’ engine cooling technology. Recent advancements in Tur Coolant Drain Tube technology have further improved engine performance and reliability, showcasing Cummins’ dedication to pushing the boundaries of what is possible in engine cooling solutions 4.

Real-World Applications and Case Studies

The effectiveness of the Tur Coolant Drain Tube is evident in numerous real-world applications. Case studies have shown how this component has prevented engine failures in commercial trucks, highlighting its critical role in engine maintenance 1.

Testimonials from fleet operators and mechanics underscore the effectiveness of Cummins parts, with many praising the durability and reliability of the Tur Coolant Drain Tube. Industry experts also share best practices for using and maintaining this component, offering tips to maximize its lifespan and efficiency 2.

Compatibility with Cummins Engines

The Tur Coolant Drain Tube, identified by the part number 5336199 and manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. This component plays a crucial role in the engine’s cooling system by facilitating the drainage of coolant, ensuring that the system remains efficient and free from contaminants.

ISB6.7 CM2250

The ISB6.7 CM2250 engine benefits from the Tur Coolant Drain Tube, which is engineered to integrate smoothly with the engine’s design. This part is essential for maintaining optimal coolant levels and preventing coolant buildup, which can lead to overheating and potential engine damage.

ISB6.7 CM2350 B101

Similarly, the ISB6.7 CM2350 B101 engine is compatible with the Tur Coolant Drain Tube. This part ensures that the engine’s cooling system operates efficiently, providing reliable performance and longevity. The design of the tube allows for easy installation and effective coolant drainage, contributing to the overall health of the engine.

Grouping for Clarity

When considering the compatibility of the Tur Coolant Drain Tube with these engines, it is important to note that both the ISB6.7 CM2250 and ISB6.7 CM2350 B101 engines share a similar architecture in their cooling systems. This commonality allows the part to be used interchangeably across these engine models, simplifying maintenance and repair processes.

Role of Part 5336199 Tur Coolant Drain Tube in Engine Systems

The Part 5336199 Tur Coolant Drain Tube is an essential component in the efficient operation of both the plumbing and turbocharger systems within an engine.

In the plumbing system, this tube facilitates the drainage of coolant from the turbocharger, ensuring that any accumulated coolant is effectively removed. This process is important for maintaining the integrity of the cooling system, preventing coolant buildup which could lead to inefficiencies or potential damage. The tube connects to the coolant passages within the turbocharger housing, allowing for a controlled and consistent flow of coolant out of the system.

Within the turbocharger system, the Tur Coolant Drain Tube plays a significant role in preserving the turbocharger’s performance and longevity. By allowing coolant to be drained regularly, it helps in reducing the risk of coolant contamination within the turbocharger, which can adversely affect its operation. The tube is typically integrated into the turbocharger’s coolant circuit, ensuring that coolant can be expelled without interfering with the turbocharger’s primary function of compressing intake air.

Overall, the Tur Coolant Drain Tube is a vital link between the plumbing and turbocharger systems, contributing to the smooth and reliable operation of the engine by ensuring proper coolant management.

Conclusion

The Cummins 5336199 Tur Coolant Drain Tube is a vital component in the engine cooling system, playing a crucial role in maintaining optimal engine temperature and performance. Cummins’ commitment to quality and innovation ensures that this part meets the high standards required for commercial truck applications 3.

Regular maintenance and inspection of the Tur Coolant Drain Tube are essential for ensuring engine efficiency and longevity. By understanding its function and importance, mechanics and engineers can better appreciate the role of this component in engine operations and the value Cummins brings to the industry 4.

-

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. , .

↩ ↩ ↩ -

Barton, David C and Fieldhouse, John D. Automotive Chassis Engineering. , .

↩ ↩ ↩ -

Hilgers, Michael. Electrical Systems and Mechatronics. , .

↩ ↩ ↩ ↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. , .

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.