This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

A wiring harness is a collection of wires, connectors, and related components that transmit electrical power and signals throughout a vehicle. In vehicles, wiring harnesses play a vital role by organizing and protecting the electrical connections that link various systems and components. In heavy-duty trucks, wiring harnesses are particularly important due to the complexity and robustness required to handle the demanding conditions these vehicles often face. A typical wiring harness includes insulated wires, connectors, terminals, and sometimes fuses or relays, all designed to ensure reliable electrical performance 1.

Purpose of the 5341384 Wiring Harness

The 5341384 Wiring Harness by Cummins is designed to facilitate the electrical connections necessary for the operation of heavy-duty trucks. This harness integrates with various systems such as the engine control module (ECM), sensors, and other electronic components to ensure efficient and reliable performance. By providing a structured and protected pathway for electrical signals and power, the 5341384 Wiring Harness helps maintain the functionality of critical truck systems, contributing to overall vehicle performance and reliability 2.

Key Features of the 5341384 Wiring Harness

The 5341384 Wiring Harness features a robust design that includes high-quality materials to enhance its functionality and durability. It is constructed using durable insulation and corrosion-resistant connectors to withstand the harsh environments typical of heavy-duty truck operations. The harness is engineered to be flexible yet sturdy, allowing it to fit snugly within the truck’s chassis while resisting wear and tear. Additionally, the harness includes precise connectors and terminals that ensure secure and reliable electrical connections 3.

Benefits of Using the 5341384 Wiring Harness

Using the 5341384 Wiring Harness offers several benefits. It improves electrical efficiency by providing a well-organized and protected pathway for electrical signals and power. This reduces the risk of short circuits and other electrical issues that can arise from loose or damaged wires. The harness’s durable construction ensures it can withstand the rigors of heavy-duty truck use, providing long-term reliability even under harsh conditions. Additionally, the precise design of the harness helps maintain consistent electrical performance, contributing to the overall efficiency and reliability of the truck’s systems 4.

Installation and Integration

When installing the 5341384 Wiring Harness, it is important to follow guidelines to ensure proper fit and function. Begin by identifying the correct routing paths within the truck’s chassis to avoid interference with other components. Use appropriate tools to secure the harness in place, ensuring that all connections are tight and secure. It is also important to verify that the harness is compatible with the truck’s existing electrical system to prevent any conflicts or issues. Following these best practices will help ensure the harness integrates seamlessly with the truck’s electrical system 5.

Troubleshooting Common Issues

Common issues with wiring harnesses can include loose connections, damaged wires, or faulty components. To troubleshoot these problems, start by inspecting the harness for any visible signs of wear or damage. Check all connections to ensure they are secure and free from corrosion. If a specific component is not functioning correctly, trace the wiring back to identify any breaks or shorts. Addressing these issues promptly can help maintain the reliability and performance of the truck’s electrical system 6.

Maintenance Tips

Regular maintenance of the 5341384 Wiring Harness is important to ensure long-term reliability and performance. Inspect the harness periodically for signs of wear and tear, corrosion, or other potential issues. Clean any corrosion from connectors and terminals to maintain good electrical connections. Ensure that the harness remains securely routed and protected from physical damage. Following these maintenance tips will help extend the lifespan of the wiring harness and ensure consistent performance 7.

Safety Considerations

When working with wiring harnesses, it is important to observe safety considerations to prevent electrical hazards. Use appropriate tools and personal protective equipment (PPE) when handling the harness to avoid injury. Ensure that the truck’s battery is disconnected before beginning any work on the electrical system to prevent accidental shorts or shocks. Adhere to safety protocols and guidelines provided by Cummins to ensure a safe working environment 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industry. The company is committed to providing high-quality components, including the 5341384 Wiring Harness, that meet the demanding requirements of heavy-duty applications. Cummins’ focus on quality and innovation ensures that their products contribute to the reliable and efficient performance of vehicles 9.

Cummins Engine Wiring Harness 5341384 Compatibility

The Cummins Wiring Harness part number 5341384 is designed to integrate seamlessly with specific Cummins engine models, ensuring reliable electrical connectivity and performance. This wiring harness is compatible with the following engines:

QSB6.7 CM2350 B105 and QSL9 CM2350 L102

The 5341384 wiring harness is engineered to fit the QSB6.7 CM2350 B105 and QSL9 CM2350 L102 engines. These engines are part of Cummins’ lineup, known for their robust performance and reliability in various applications. The harness is meticulously designed to connect all necessary electrical components, ensuring that the engine operates efficiently and safely.

The harness is crafted to handle the specific electrical demands of these engines, providing a secure and durable connection that can withstand the rigors of continuous operation. Its design ensures that all electrical pathways are correctly routed, minimizing the risk of interference and ensuring optimal performance.

By using the 5341384 wiring harness, technicians and operators can be confident that their QSB6.7 CM2350 B105 and QSL9 CM2350 L102 engines will maintain reliable electrical connections, contributing to the overall longevity and efficiency of the engine 10.

Role of Part 5341384 Wiring Harness in Engine Systems

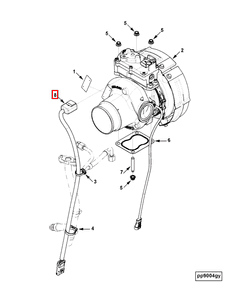

The 5341384 Wiring Harness is an integral component in the electrical system of engine assemblies, particularly when integrated with a turbocharger. This harness facilitates the connection between various electrical components and the engine control unit (ECU), ensuring seamless communication and operation.

Integration with Turbocharger

When paired with a turbocharger, the 5341384 Wiring Harness plays a significant role in managing the electrical signals that control the turbocharger’s operation. It connects sensors such as the turbocharger speed sensor and the wastegate actuator to the ECU. This allows for real-time monitoring and adjustment of the turbocharger’s performance, optimizing air intake and exhaust flow.

Sensor Connectivity

The harness provides the necessary pathways for sensors to transmit data to the ECU. Key sensors connected via this harness include:

- Turbocharger Speed Sensor: Monitors the rotational speed of the turbocharger, allowing the ECU to make adjustments for optimal performance.

- Boost Pressure Sensor: Measures the pressure of the air entering the engine, enabling the ECU to regulate the turbocharger’s boost levels.

- Intake Air Temperature Sensor: Provides data on the temperature of the intake air, which is crucial for the ECU to adjust fuel delivery and ignition timing.

Actuator Control

In addition to sensor connectivity, the 5341384 Wiring Harness controls various actuators within the engine system:

- Wastegate Actuator: Regulates the turbocharger’s boost pressure by controlling the wastegate valve. The harness ensures that the ECU can open or close the wastegate as needed to maintain safe and efficient boost levels.

- Variable Geometry Turbocharger (VGT) Actuator: In engines equipped with VGT, the harness allows the ECU to adjust the turbocharger’s vanes for optimal airflow and performance across different engine speeds.

Electrical Integrity

The 5341384 Wiring Harness is designed to withstand the harsh environment of the engine compartment, including high temperatures and vibrations. Its robust construction ensures reliable electrical connections, preventing issues such as signal loss or intermittent faults that could affect engine performance.

Enhanced Performance and Efficiency

By providing a reliable and efficient means of electrical communication between the turbocharger, sensors, and ECU, the 5341384 Wiring Harness contributes to the overall performance and efficiency of the engine. It enables precise control over the turbocharger’s operation, leading to improved throttle response, increased power output, and better fuel economy.

Conclusion

The 5341384 Wiring Harness by Cummins is a critical component for the reliable and efficient operation of heavy-duty trucks. Its robust design, precise connectivity, and compatibility with specific Cummins engines ensure that it can withstand the demanding conditions of heavy-duty applications. By facilitating seamless electrical communication between various components and the ECU, this part enhances the overall performance and efficiency of the engine, contributing to the longevity and reliability of the vehicle.

-

Carroll, Douglas R. Energy Efficiency of Vehicles. SAE International, 2020.

↩ -

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ -

Osgood, Libby, Gayla Cameron, and Emma Christensen. Engineering Mechanics: Statics. Creative Commons, 2024.

↩ -

ElSayed, Mohamed PE. Fundamentals of Integrated Vehicle Realization. SAE International, 2017.

↩ -

Cummins Inc. ISF3.8 CM2220 F103 Service Manual (4310839).

↩ -

Cummins Inc. ISF3.8 CM2220 F103 Service Manual (4310839).

↩ -

Cummins Inc. ISF3.8 CM2220 F103 Service Manual (4310839).

↩ -

Cummins Inc. ISF3.8 CM2220 F103 Service Manual (4310839).

↩ -

Cummins Inc. ISF3.8 CM2220 F103 Service Manual (4310839).

↩ -

Cummins Inc. ISF3.8 CM2220 F103 Service Manual (4310839).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.