This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5347634 Compressor Water Inlet Tube, manufactured by Cummins, is a component designed for use in heavy-duty trucks. Cummins, a well-established name in the engine manufacturing industry, produces this part to enhance the operational efficiency of truck engines. This tube is integral to the engine’s cooling and performance systems, ensuring that heavy-duty trucks operate smoothly under demanding conditions.

Basic Concepts and Functionality

The Compressor Water Inlet Tube operates on the fundamental principle of managing the flow of coolant into the compressor. This management is crucial for maintaining optimal temperatures within the engine system. By regulating coolant flow, the tube helps in dissipating heat generated during engine operation, which is vital for sustaining engine performance and longevity 1.

Purpose and Role in Truck Operation

This Cummins part serves a specific function within a truck’s engine system. It directs coolant into the compressor, playing a role in the cooling process that prevents overheating. This cooling is necessary for the efficient operation of the compressor and, by extension, the entire engine. Proper cooling ensures that the engine components function within their designed temperature ranges, contributing to overall engine efficiency and reliability 2.

Key Features

This Compressor Water Inlet Tube is characterized by its robust design and the use of high-quality materials. These features are intended to enhance its performance and durability. The tube is engineered to withstand the high pressures and temperatures typical in heavy-duty truck engines. Its design also facilitates easy installation and maintenance, which is beneficial for fleet operators.

Benefits

Utilizing the 5347634 can lead to several advantages. These include improved engine efficiency due to effective cooling, enhanced durability of engine components, and potential cost savings for fleet operators through reduced maintenance needs and extended component lifespan.

Installation and Compatibility

For the proper installation of the Compressor Water Inlet Tube, it is important to follow manufacturer guidelines. Compatibility with various truck models and engine types should be verified to ensure optimal performance and integration within the engine system.

Maintenance and Troubleshooting

Regular maintenance of the Compressor Water Inlet Tube is recommended to ensure its longevity and optimal performance. This includes periodic checks for leaks, corrosion, or blockages. Troubleshooting common issues, such as reduced coolant flow or leaks, can often be addressed through routine maintenance practices.

Performance Impact

The 5347634 influences the overall performance of the truck’s engine. Effective cooling provided by the tube contributes to improved fuel efficiency, consistent power output, and enhanced engine reliability. These factors are crucial for the operational effectiveness of heavy-duty trucks 3.

Cummins: A Brief Overview

Cummins Inc. is a leader in the engine manufacturing industry, known for its commitment to innovation and quality. With a rich history of producing reliable and efficient engines, Cummins continues to be at the forefront of technological advancements in the automotive sector. Their expertise and dedication to quality are evident in their product line, including the Compressor Water Inlet Tube.

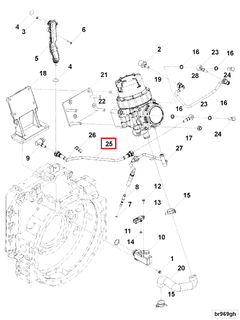

Cummins Engine Part 5347634: Compressor Water Inlet Tube

The Compressor Water Inlet Tube, identified by part number 5347634, is a critical component in the cooling system of certain Cummins engines. This part is integral to the efficient operation of the engine’s cooling system, ensuring that the compressor section receives adequate water flow for optimal temperature regulation.

Application in Cummins Engines

The Compressor Water Inlet Tube is specifically designed to fit the following Cummins engines:

- QSB4.5 CM2250 EC

This part is engineered to seamlessly integrate with the cooling systems of these engines, providing a reliable pathway for water to enter the compressor. Its precise fit and robust construction ensure that the cooling process is uninterrupted, which is vital for maintaining engine performance and longevity.

Importance of the Compressor Water Inlet Tube

The Compressor Water Inlet Tube plays a pivotal role in the engine’s cooling mechanism. By directing water to the compressor, it helps dissipate heat generated during operation. This is particularly important in high-performance engines where thermal management is crucial to prevent overheating and ensure consistent performance.

Compatibility and Installation

The Compressor Water Inlet Tube is designed to be compatible with the specified Cummins engines, ensuring a straightforward installation process. Technicians and mechanics can rely on this part to fit perfectly within the engine’s cooling system, facilitating easy maintenance and replacement when necessary.

Reliability and Durability

Manufactured by Cummins, the Compressor Water Inlet Tube is built to withstand the rigors of engine operation. Its durable construction ensures a long service life, reducing the need for frequent replacements and contributing to the overall reliability of the engine.

Role of Part 5347634 Compressor Water Inlet Tube in Engine Systems

The Compressor Water Inlet Tube, identified by part number 5347634, is integral to the efficient operation of various engine systems. It facilitates the precise introduction of water into the compressor, which is essential for cooling and enhancing the performance of the compressor itself.

Interaction with the Crankcase

The Compressor Water Inlet Tube works in conjunction with the crankcase to maintain optimal engine temperature. As the compressor operates, it generates heat. The water introduced via the inlet tube absorbs this heat, preventing overheating and ensuring the compressor functions within its designed parameters. This cooling effect indirectly supports the crankcase by helping to maintain a stable engine temperature, which is vital for the longevity and efficiency of the crankcase and its components.

Contribution to the Breather System

In engines equipped with a breather system, the Compressor Water Inlet Tube plays a supportive role. The breather system is designed to release pressure build-up within the crankcase, which can occur due to the combustion process. By keeping the compressor cool and efficient, the inlet tube ensures that the engine operates smoothly, reducing the likelihood of excessive pressure build-up. This, in turn, allows the breather system to function more effectively, maintaining a balanced pressure environment within the engine.

Overall Engine Performance

The efficient operation of the Compressor Water Inlet Tube contributes to the overall performance and reliability of the engine. By ensuring that the compressor remains cool and operates efficiently, the inlet tube helps to maintain consistent engine performance. This is particularly important in high-performance or high-stress engine applications where maintaining optimal operating conditions is essential.

Conclusion

The 5347634 Compressor Water Inlet Tube is a vital component in the cooling system of Cummins engines, particularly in heavy-duty truck applications. Its role in managing coolant flow to the compressor ensures efficient engine operation, contributing to improved fuel efficiency, consistent power output, and enhanced engine reliability. The robust design and high-quality materials used in this part ensure durability and ease of maintenance, making it a valuable asset for fleet operators. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, ultimately leading to cost savings and extended engine lifespan.

-

Diesel Emissions and Their Control: Second Edition, Addy Majewski and Hannu Jaskelainen, SAE International, 2023

↩ -

Gas Turbine Engineering Handbook, Second Edition, Meherwan P. Boyce, Gulf Professional Publishing, 2002

↩ -

Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves, Angelina Eret, Springer Nature, 2024

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.