This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5394360 Combustion Leak Tester is a specialized diagnostic tool designed for the maintenance and operation of commercial trucks. This device is instrumental in detecting combustion leaks within diesel engines, which can significantly impact engine performance and safety. By identifying leaks early, it aids in maintaining engine efficiency and prolonging the lifespan of the vehicle 2.

Basic Concepts of Combustion Leak Testing

A combustion leak tester is a diagnostic instrument used to detect the presence of combustion gases in cooling systems. It operates on the principle that combustion gases, primarily nitrogen oxides, can leak into the cooling system through cracks or faults in the engine block, cylinder head, or head gasket. The tester measures the concentration of these gases, providing an indication of the presence and severity of a leak 1.

Purpose of the Cummins 5394360 Combustion Leak Tester

The Cummins 5394360 Combustion Leak Tester plays a significant role in the maintenance of trucks by identifying combustion leaks. This identification is crucial for preventing engine damage, ensuring optimal performance, and maintaining safety standards. By detecting leaks early, the tester helps in scheduling timely repairs, thus avoiding more severe engine issues down the line 2.

Key Features

The Cummins 5394360 Combustion Leak Tester is equipped with several features that enhance its functionality. Its design includes precise sensors for detecting combustion gases, a user-friendly interface for easy operation, and robust construction for durability in a commercial truck environment. Technological advancements in the tester allow for accurate and reliable leak detection, making it a valuable tool for fleet maintenance 2.

Benefits of Using the Cummins 5394360 Combustion Leak Tester

Utilizing the Cummins 5394360 Combustion Leak Tester offers several advantages. It contributes to improved engine performance by ensuring that combustion leaks are addressed promptly. This early detection can lead to increased safety, as it prevents potential engine failures that could occur while the vehicle is in operation. Additionally, by identifying issues early, the tester can result in cost savings through reduced repair costs and extended engine life 2.

Troubleshooting and Maintenance Suggestions

Common issues with the Cummins 5394360 Combustion Leak Tester may include sensor inaccuracies or device malfunctions. Troubleshooting steps involve checking the sensor calibration, ensuring proper connection to the cooling system, and verifying the device’s settings. Regular maintenance practices, such as cleaning the sensors and performing routine checks, are recommended to ensure the tester operates at peak efficiency 2.

Integration with Cummins Engines

The Cummins 5394360 Combustion Leak Tester is designed to integrate seamlessly with various Cummins engine models. This integration enhances the diagnostic capabilities of the engine, providing comprehensive monitoring and early detection of potential issues. It is an invaluable tool for maintaining the health and performance of Cummins engines across different applications 2.

User Training and Certification

Cummins offers training and certification programs for users of the 5394360 Combustion Leak Tester. These programs are designed to ensure that users are proficient in operating the tester and interpreting its results accurately. Proper training is vital for maximizing the effectiveness of the tester in fleet maintenance routines 2.

Environmental and Safety Considerations

The use of the Cummins 5394360 Combustion Leak Tester contributes to environmental and safety benefits. By detecting and addressing combustion leaks, it helps in reducing emissions from commercial trucks, aligning with environmental regulations. Additionally, it enhances workplace safety by preventing engine failures that could pose risks to operators and other road users 2.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a strong reputation in the diesel engine and components industry, Cummins is committed to innovation, quality, and customer satisfaction. The company’s extensive product line and technological advancements make it a trusted partner in the commercial vehicle sector 2.

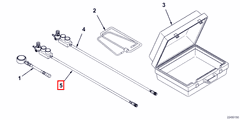

Role of Part 5394360 Combustion Leak Tester in Engine Diagnostic Tool Kit

The Part 5394360 Combustion Leak Tester is an essential component within an Engine Diagnostic Tool Kit. It is specifically designed to detect combustion leaks in an engine’s cylinders, which can be indicative of issues such as a blown head gasket, cracked cylinder head, or damaged piston rings.

When integrated into an Engine Diagnostic Tool Kit, the Combustion Leak Tester operates by introducing a non-toxic gas into the cooling system. If there is a leak in the combustion chamber, the gas will be drawn into the cylinder during the compression stroke and subsequently detected in the exhaust by the tester. This process allows mechanics and engineers to pinpoint the exact cylinder with the leak, facilitating targeted repairs and minimizing unnecessary disassembly.

The Combustion Leak Tester complements other tools in the kit, such as multimeters, oscilloscopes, and pressure gauges, by providing specific diagnostic data related to combustion integrity. This detailed information is invaluable for performing thorough engine assessments and ensuring precise diagnoses.

Incorporating the Combustion Leak Tester into routine diagnostic procedures enhances the overall efficiency and accuracy of engine maintenance, leading to more reliable and cost-effective repairs 2.

Conclusion

The Cummins 5394360 Combustion Leak Tester is a vital tool in the maintenance and operation of commercial trucks. Its ability to detect combustion leaks early contributes to improved engine performance, safety, and cost savings. With its integration into Cummins engines and comprehensive training programs, this Cummins part ensures that fleet maintenance routines are efficient and effective. Additionally, its role in environmental and safety considerations underscores its importance in modern automotive maintenance practices.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.