This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

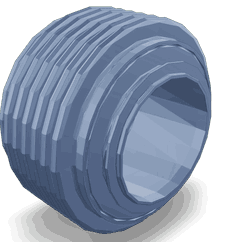

The 5416017 Bellows, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts that contribute to the efficiency and reliability of commercial vehicles. This part is significant in this context as it plays a specific role in the mechanical systems of trucks, ensuring smooth operation and durability.

Basic Concepts of Bellows

Bellows are flexible elements used in various mechanical systems to accommodate movement, vibration, and thermal expansion while maintaining a seal. They consist of multiple convolutions that allow them to flex and expand. Commonly constructed from materials like rubber, metal, or a combination of both, bellows are chosen for their flexibility, durability, and resistance to environmental factors. The material selection depends on the specific application and the operating conditions the bellows will encounter 1.

Purpose of the 5416017 Bellows in Truck Operations

The 5416017 Bellows is designed to serve a specific function within the mechanical systems of commercial trucks. It allows for the necessary movement and flexibility in components that experience vibration or thermal expansion, while also providing a seal to prevent leaks. This contributes to the overall functionality and efficiency of the vehicle by ensuring that systems operate smoothly without undue wear or failure 2.

Key Features of the 5416017 Bellows

The 5416017 Bellows is characterized by several design elements that make it suitable for its intended application. Its construction typically involves materials that offer a balance of flexibility and durability. The bellows may incorporate metal reinforcements to enhance strength and longevity. Unique design aspects could include specific convolution patterns or end connections that ensure a secure fit and optimal performance in the truck’s mechanical system 3.

Benefits of Using the 5416017 Bellows

Incorporating the 5416017 Bellows into truck systems offers several advantages. These include improved system performance due to its ability to accommodate movement and vibration, enhanced durability thanks to its material composition, and potential cost-effectiveness over time by reducing the need for frequent replacements or repairs 4.

Installation and Integration

Proper installation of the 5416017 Bellows is crucial for its effective operation. Guidelines for installation may include ensuring the bellows is correctly aligned with the components it connects, using any specified tools for a secure fit, and verifying that it can move freely without obstruction. Prerequisites might involve inspecting the installation area for cleanliness and the absence of any damage that could affect the bellows’ performance.

Troubleshooting Common Issues

Common problems associated with the 5416017 Bellows can include signs of wear, such as cracks or leaks, and potential failure modes like complete rupture. Troubleshooting steps may involve inspecting the bellows for visible damage, checking for proper alignment and fit, and ensuring that the operating conditions do not exceed the bellows’ design specifications. Corrective actions could range from minor adjustments to replacement of the bellows.

Maintenance Practices

To ensure the longevity and optimal performance of the 5416017 Bellows, recommended maintenance routines include regular inspection intervals to check for signs of wear or damage, cleaning procedures to remove any contaminants that could affect its operation, and following any specific care instructions provided by the manufacturer. These practices help maintain the bellows’ integrity and functionality over time.

Cummins: A Brief Overview

Cummins is a manufacturer with a rich history in the commercial truck industry, known for producing a wide range of parts and engines that are recognized for their quality and reliability. Their product range includes components like the 5416017 Bellows, which are designed to meet the demanding requirements of commercial vehicle operations. Cummins’ reputation in the industry is built on a commitment to innovation, quality, and customer satisfaction.

Bellows Part 5416017 in Cummins Engines

The Bellows part 5416017, manufactured by Cummins, is a critical component in several of their engine models. This part is integral to the proper functioning of the engines, ensuring efficient operation and longevity. Here’s how it fits into specific Cummins engines:

QSK19 CM2350 K105

In the QSK19 CM2350 K105 engine, the Bellows part 5416017 plays a vital role in maintaining the seal between moving parts. This engine is known for its robust design and high performance, and the bellows help in accommodating the thermal expansion and contraction of the engine components, thereby preventing leaks and ensuring smooth operation.

QST30 CM2350 T101

Similarly, in the QST30 CM2350 T101 engine, the Bellows part 5416017 is essential for maintaining the integrity of the engine’s sealing system. This engine variant is designed for heavy-duty applications, and the bellows help in managing the stresses caused by the engine’s operational dynamics, contributing to the engine’s overall reliability and efficiency.

Grouping of Engines

Both the QSK19 CM2350 K105 and QST30 CM2350 T101 engines fall under the category of high-performance, heavy-duty engines. The Bellows part 5416017 is crucial in these engines due to their demanding operational environments. The bellows’ flexibility and durability make it an ideal component for accommodating the mechanical stresses and thermal variations these engines experience.

Role of Part 5416017 Bellows in Engine Systems

The part 5416017 Bellows is an essential component in the arrangement of various engine systems, particularly in the context of turbochargers. Its primary function is to provide a flexible connection between static and dynamic parts of the engine, accommodating the movement and vibrations that occur during operation.

In turbocharger systems, the Bellows is often situated between the turbine housing and the compressor housing. This placement allows it to absorb the thermal expansion and mechanical vibrations that are inherent in the high-speed rotation of the turbocharger. By doing so, it ensures that the connection remains intact and functional, preventing leaks and maintaining the efficiency of the turbocharger.

Additionally, the Bellows plays a significant role in the overall durability and reliability of the turbocharger. Its flexibility helps in reducing stress on the connecting components, which can otherwise lead to premature wear or failure. This is particularly important in high-performance engines where the turbocharger operates under extreme conditions.

Furthermore, the Bellows contributes to the sealing integrity of the turbocharger system. It helps in maintaining the proper pressure differentials required for efficient turbocharging, thereby enhancing the engine’s performance and fuel efficiency.

Conclusion

In summary, the part 5416017 Bellows is a vital element in the arrangement of turbocharger systems, providing flexibility, durability, and sealing integrity that are essential for the optimal functioning of the engine. Its role in accommodating movement, vibration, and thermal expansion ensures the smooth operation and longevity of commercial truck engines, particularly in high-performance and heavy-duty applications.

-

Gasoline Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2015

↩ -

Fundamentals of Medium-Heavy Duty Diesel Engines, Gus Wright, Jones & Bartlett Learning, 2015

↩ -

Design and Development of Heavy Duty Diesel Engines: A Handbook, P. A. Lakshminarayanan, Avinash Kumar Agarwal, Springer, 2019

↩ -

A Practical Approach to Motor Vehicle Engineering and Maintenance, Allan Bonnick, Elsevier, 2004

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.