This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3031701 Instrument Panel is a vital component in the operation of commercial trucks. It serves as the central hub for monitoring and displaying critical information about the vehicle’s performance and status. This panel integrates various systems and provides drivers with real-time data, enhancing both safety and operational efficiency.

Basic Concepts of Instrument Panels

An instrument panel, commonly referred to as a dashboard, is a control center in a vehicle that houses various gauges, indicators, and controls. It typically includes components such as speedometers, tachometers, fuel gauges, and warning lights. The instrument panel functions by receiving data from sensors throughout the vehicle and displaying this information to the driver in an easily understandable format 1.

Purpose of the Cummins 3031701 Instrument Panel

The Cummins 3031701 Instrument Panel plays a specific role in the operation of a truck by providing comprehensive data on engine performance, fuel levels, and other critical parameters. It is designed to integrate seamlessly with other truck systems, such as the engine, transmission, and braking systems, to offer a cohesive view of the vehicle’s status. This integration allows for better monitoring and management of the truck’s operations 2.

Key Features

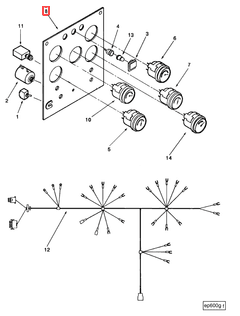

The Cummins 3031701 Instrument Panel boasts several primary features that enhance its functionality. These include various display types, such as digital and analog gauges, sensor integration for real-time data collection, and user interface elements like buttons and control knobs. These features work together to provide drivers with accurate and timely information 3.

Benefits

The advantages of the Cummins 3031701 Instrument Panel include improved driver awareness through clear and comprehensive data display, enhanced safety features such as warning lights and alerts, and increased operational efficiency by allowing for better monitoring and management of the truck’s systems 4.

Common Issues and Troubleshooting

Frequent problems associated with instrument panels can include inaccurate readings, malfunctioning sensors, and display failures. Potential causes may range from electrical issues to physical damage. Recommended troubleshooting steps involve checking connections, testing sensors, and ensuring the panel is receiving proper power.

Maintenance Tips

Routine maintenance practices for the Cummins 3031701 Instrument Panel include regular inspections for signs of wear or damage, ensuring all connections are secure, and keeping the panel clean to prevent dust and debris from affecting its performance. These practices help ensure the longevity and reliability of the instrument panel.

Integration with Truck Systems

The Cummins 3031701 Instrument Panel interacts with other truck systems by receiving data from sensors located throughout the vehicle. This data is then processed and displayed on the panel, providing drivers with a comprehensive view of the truck’s performance. Systems such as the engine, transmission, and braking systems are all monitored and displayed through the instrument panel.

User Interface and Controls

The user interface elements on the Cummins 3031701 Instrument Panel include various buttons, displays, and control knobs. These elements allow drivers to interact with the panel, adjust settings, and view different types of information. The design of these interface elements is intended to be intuitive and easy to use, even in challenging driving conditions.

Safety Features

The Cummins 3031701 Instrument Panel incorporates several safety features to enhance driver and passenger safety. These features include warning lights for critical issues such as low oil pressure or overheating, alerts for maintenance needs, and diagnostic indicators that help identify potential problems before they become serious.

Technological Advancements

The Cummins 3031701 Instrument Panel features several technological innovations that enhance its functionality. These include digital displays for clear and precise data presentation, connectivity options for integration with other systems, and software updates that allow for improvements and additions over time.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation and excellence in the automotive industry. The company’s product range includes a variety of engines, components, and systems designed to meet the needs of commercial and industrial applications.

Cummins Instrument Panel 3031701 Compatibility with Various Engines

The Cummins Instrument Panel 3031701 is designed to integrate seamlessly with a variety of engine models, ensuring compatibility and ease of installation. This instrument panel is engineered to provide essential data and control features, enhancing the operational efficiency of the engines it is paired with.

Cummins K19, K38, K50 Engines

The Cummins K19, K38, and K50 engines are part of a series known for their robust performance and reliability. The 3031701 instrument panel is specifically tailored to fit these engines, offering a user-friendly interface that displays critical engine parameters such as RPM, fuel consumption, and temperature. This compatibility ensures that operators can monitor and control these engines effectively, maintaining optimal performance and reducing the risk of downtime.

Cummins N14 MECHANICAL Engine

The Cummins N14 MECHANICAL engine is renowned for its durability and power, often used in heavy-duty applications. The 3031701 instrument panel is engineered to interface with the N14 MECHANICAL engine, providing comprehensive monitoring and control capabilities. This ensures that operators can maintain precise control over engine operations, enhancing both efficiency and safety.

Cummins NH/NT 855 Engines

The Cummins NH/NT 855 engines are designed for agricultural and industrial applications, offering a balance of power and efficiency. The 3031701 instrument panel is compatible with these engines, providing a clear and intuitive display of engine data. This compatibility allows for effective monitoring and control, ensuring that these engines operate at peak performance.

Cummins V28 Engine

The Cummins V28 engine is known for its high torque output and reliability, making it suitable for a range of applications. The 3031701 instrument panel is designed to fit the V28 engine, offering a comprehensive set of features for monitoring and controlling engine performance. This ensures that operators can maintain optimal engine operation, enhancing both efficiency and longevity.

By ensuring compatibility with these diverse engine models, the Cummins Instrument Panel 3031701 provides a versatile and reliable solution for engine monitoring and control.

Role of Part 3031701 Instrument Panel in Engine Systems

The Part 3031701 Instrument Panel serves as the central hub for monitoring and displaying vital engine parameters. It interfaces with various engine components to provide real-time data to the operator, ensuring informed decision-making and efficient engine management.

Integration with Engine Components

-

Engine Instrument Panel: The 3031701 Instrument Panel is designed to work seamlessly with the Engine Instrument Panel. It receives data from multiple sensors distributed throughout the engine system, such as temperature, pressure, and fuel level sensors. This data is then processed and displayed in an easy-to-read format, allowing for quick assessment of engine health and performance.

-

Instrument Panel: When integrated with a standard Instrument Panel, Part 3031701 enhances the functionality by providing additional metrics specific to engine operation. This includes RPM (Revolutions Per Minute), oil pressure, coolant temperature, and other critical metrics that are essential for maintaining optimal engine performance.

Data Flow and Display

The 3031701 Instrument Panel collects data from the following components:

-

Temperature Sensors: Located in various parts of the engine, these sensors measure the temperature of coolant, oil, and exhaust gases. The Instrument Panel displays this information to prevent overheating and ensure the engine operates within safe temperature ranges.

-

Pressure Sensors: These sensors monitor oil pressure and fuel pressure. The Instrument Panel provides real-time readings, allowing for immediate detection of any anomalies that could indicate a leak or malfunction.

-

Fuel Level Sensors: By measuring the amount of fuel in the tank, the Instrument Panel ensures that the operator is aware of the remaining fuel, preventing unexpected shutdowns due to fuel depletion.

-

RPM Sensors: These sensors measure the rotational speed of the engine. The Instrument Panel displays this data, helping the operator maintain the engine within its optimal operating range.

Operator Interaction

The 3031701 Instrument Panel is designed for intuitive interaction. It often includes:

-

Digital Displays: Clear, backlit screens that show numerical values and graphical representations of engine parameters.

-

Warning Lights: Indicators that illuminate when certain thresholds are exceeded, alerting the operator to potential issues.

-

Control Buttons: Allows the operator to cycle through different display modes, reset warning lights, and access diagnostic information.

By providing a comprehensive view of engine performance, the 3031701 Instrument Panel plays a significant role in the maintenance and operation of engine systems, facilitating proactive management and enhancing overall efficiency.

Conclusion

The Cummins 3031701 Instrument Panel is an essential component for the efficient and safe operation of commercial trucks. Its integration with various engine systems, comprehensive data display, and user-friendly interface make it a valuable tool for operators. Regular maintenance and proper troubleshooting can ensure the longevity and reliability of this part, contributing to the overall performance and safety of the vehicle.

-

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ -

Limpert, Rudolf. Brake Design and Safety, Third Edition. SAE International, 2011.

↩ -

Sobey, Ed. A Field Guide to Automotive Technology. Chicago Review Press, 2009.

↩ -

Halderman, James D. Automotive Principles: Diagnosis and Service. Prentice Hall, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.