This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3002184 Clevis Pin is a specialized component designed for use in commercial trucks. Its purpose is to facilitate the connection and secure attachment of various truck components, ensuring the efficient and reliable operation of the vehicle. The significance of this part lies in its role in maintaining the structural integrity and functional performance of truck systems.

Basic Concepts of Clevis Pins

A clevis pin is a cylindrical fastener featuring a head at one or both ends. It is commonly used in mechanical systems to connect two parts that need to pivot relative to each other. Within the context of truck components, clevis pins are integral to the operation of linkages, control arms, and other pivotal connections. They allow for movement while maintaining a secure attachment, which is vital for the proper functioning of the truck’s mechanical systems 1.

Role of the 3002184 Clevis Pin in Truck Operation

The Cummins 3002184 Clevis Pin plays a specific role in the operation of a truck by connecting and securing various components. It is often used in applications where pivoting motion is required, such as in the steering and suspension systems. By providing a reliable connection point, the clevis pin ensures that these components can move as intended without detaching, which is crucial for the safe and efficient operation of the truck.

Key Features of the 3002184 Clevis Pin

The Cummins 3002184 Clevis Pin is characterized by several key features that enhance its performance and durability. It is typically made from high-strength materials, such as alloy steel, which provides resistance to wear and corrosion. The design specifications of the pin, including its diameter and length, are tailored to meet the specific requirements of its applications. Additionally, the pin may feature a cotter pin or other locking mechanism to prevent accidental disengagement 2.

Benefits of Using the 3002184 Clevis Pin

Using the Cummins 3002184 Clevis Pin offers several benefits. Its robust construction and precise engineering contribute to improved reliability and enhanced safety in truck operations. The durability of the pin can lead to potential cost savings for fleet operators by reducing the frequency of replacements and maintenance interventions. Furthermore, the secure connection provided by the clevis pin helps to maintain the optimal performance of the truck’s mechanical systems.

Installation and Usage Guidelines

Proper installation of the Cummins 3002184 Clevis Pin is crucial for its effective function. It should be inserted through the holes of the components it is intended to connect, ensuring a snug fit without excessive force. Once in place, a cotter pin or similar locking device should be used to secure the clevis pin, preventing it from coming loose during operation. It is important to follow manufacturer guidelines and best practices to ensure the pin is installed correctly and functions as intended.

Troubleshooting Common Issues

Common problems with the Cummins 3002184 Clevis Pin may include wear, corrosion, or improper installation. If the pin shows signs of wear or damage, it should be replaced to maintain the integrity of the connection. Corrosion can be addressed by cleaning the pin and applying a protective coating. Ensuring that the pin is properly secured with a locking mechanism can prevent issues related to accidental disengagement.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3002184 Clevis Pin, regular inspection and maintenance are recommended. This includes checking for signs of wear, corrosion, or damage and ensuring that the locking mechanism is intact and functioning correctly. Following a recommended maintenance schedule can help identify potential issues before they lead to more significant problems, contributing to the overall reliability of the truck’s mechanical systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its components, including the Cummins 3002184 Clevis Pin, which is designed to meet the demanding requirements of commercial truck operations.

Cummins Clevis Pin 3002184 in Engine Applications

The Cummins Clevis Pin 3002184 is a critical component in various engine systems, ensuring the proper linkage and movement of parts. This pin is integral to the functionality of several engine models, providing stability and reliability in its applications.

K19 Engine Group

In the K19 engine series, the Clevis Pin 3002184 is utilized in the linkage systems that connect various engine components. This pin ensures that the movement between parts is smooth and precise, which is essential for the engine’s overall performance. Its design allows for the necessary flexibility while maintaining the strength required to withstand the operational stresses of the engine.

The K19 engines, known for their robust construction and efficiency, benefit significantly from the use of the Clevis Pin 3002184. This pin’s role in the linkage systems helps maintain the alignment and operation of critical engine parts, contributing to the engine’s longevity and reliability.

Role of Part 3002184 Clevis Pin in Engine Systems

The 3002184 Clevis Pin is an essential component in various engine systems, facilitating the secure connection and efficient operation of several key elements.

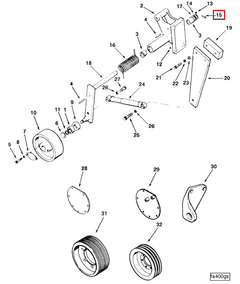

In the drive system, the Clevis Pin ensures the reliable linkage between the drive mechanism and other components, allowing for the smooth transfer of power and motion. This is particularly important in maintaining the integrity of the drive’s performance under varying operational conditions.

Within the fan assembly, the Clevis Pin plays a significant role in connecting the fan to its drive mechanism. This connection is vital for the fan’s ability to operate efficiently, ensuring proper airflow and cooling within the engine compartment.

The fan assembly idler also benefits from the Clevis Pin, as it provides a stable connection point that allows the idler to maintain its position and function correctly. This is essential for the balanced operation of the fan assembly, preventing undue stress on the system.

In the fan drive arrangement, the Clevis Pin is used to connect various components, ensuring that the drive system can operate smoothly and effectively. This connection is key to the overall efficiency and reliability of the fan drive system.

Lastly, the fan idler relies on the Clevis Pin to maintain its structural integrity and operational efficiency. The pin ensures that the idler can perform its role in the fan system without failure, contributing to the stable and consistent operation of the entire assembly.

Conclusion

The Cummins 3002184 Clevis Pin is a vital component in the operation of commercial trucks and various engine systems. Its robust construction, precise engineering, and secure connection capabilities contribute to the reliability, safety, and efficiency of truck operations. Proper installation, regular maintenance, and timely replacement of worn or damaged pins are essential practices to ensure the continued performance and longevity of this critical component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.