This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

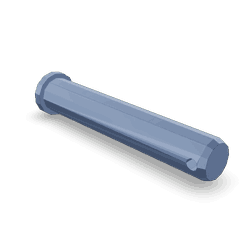

The Cummins 3086252 Clevis Pin is a specialized component designed for use in commercial truck operations. It serves a role in ensuring the secure connection of various truck components, contributing to the overall efficiency and safety of the vehicle. Understanding its purpose and significance is key to maintaining optimal truck performance.

Basic Concepts of Clevis Pins

A clevis pin is a cylindrical fastener used to connect two parts, typically in a hinge-like joint. It is commonly employed in mechanical systems to allow for pivoting motion while maintaining a secure connection. Within these systems, the clevis pin functions by fitting into a clevis, a U-shaped yoke, to create a pivot point that can withstand significant stress and movement 1.

Purpose of the Cummins 3086252 Clevis Pin

The Cummins 3086252 Clevis Pin is specifically engineered to connect and secure various components in commercial trucks. It plays a role in the truck’s suspension and steering systems by providing a reliable pivot point. This ensures that the connected parts can move as intended while maintaining structural integrity under load 2.

Key Features

The Cummins 3086252 Clevis Pin is constructed from high-quality materials, ensuring durability and resistance to wear. Its design specifications include precise dimensions to fit securely within the clevis, minimizing the risk of slippage. Additionally, it may feature unique attributes such as a cotter pin hole for added security, enhancing its performance and longevity 3.

Benefits of Using the Cummins 3086252 Clevis Pin

Utilizing the Cummins 3086252 Clevis Pin offers several advantages. It contributes to improved reliability by ensuring a secure connection between components. This enhances safety by reducing the likelihood of part failure during operation. Furthermore, it increases efficiency in truck operations by allowing for smooth and consistent movement of connected parts.

Installation Guidelines

Proper installation of the Cummins 3086252 Clevis Pin involves several steps. First, ensure that the clevis is clean and free of debris. Insert the pin into the clevis, aligning it with the pivot point. Secure the pin in place using a cotter pin or similar fastener, ensuring it is tight but not over-torqued. It is important to follow manufacturer guidelines to avoid potential pitfalls such as improper alignment or over-tightening.

Maintenance Tips

To ensure optimal performance and longevity of the Cummins 3086252 Clevis Pin, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, such as corrosion or bending. Lubrication of the pin and clevis interface can also help reduce friction and wear. Following these maintenance tips will help maintain the pin’s effectiveness over time.

Troubleshooting Common Issues

Common issues with the Cummins 3086252 Clevis Pin may include slippage, corrosion, or breakage. To address slippage, ensure the pin is properly secured with a cotter pin. Corrosion can be mitigated through regular cleaning and application of a protective coating. In the event of breakage, replace the pin with a new one of the same specifications to maintain system integrity.

Safety Considerations

When working with the Cummins 3086252 Clevis Pin, it is important to observe safety protocols. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to prevent injury. Ensure that the truck is securely parked and the engine is off before beginning any maintenance or installation procedures. Proper handling and usage of the clevis pin are crucial to avoid accidents.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the industry, Cummins is committed to quality and innovation in manufacturing components for commercial trucks. Their products are designed to meet the demanding requirements of heavy-duty applications, ensuring reliability and performance.

Cummins Clevis Pin 3086252 Compatibility with Engine Models

The Cummins Clevis Pin 3086252 is designed to fit seamlessly with a variety of Cummins engine models. This pin is a crucial component in ensuring the proper operation of the engine’s linkage systems. Below is a detailed overview of the engine models that are compatible with this specific clevis pin.

QSK19 Series

The QSK19 series engines, including the QSK19 CM2350 K144G, QSK19 CM500, QSK19 CM850 MCRS, and QSK19G, are all compatible with the Clevis Pin 3086252. This pin is essential for maintaining the integrity of the linkage systems in these engines, ensuring smooth and reliable operation.

QSK50 Series

The QSK50 CM2150 MCRS engine is also compatible with the Clevis Pin 3086252. This pin is specifically engineered to fit the unique requirements of the QSK50 series, providing the necessary strength and durability to withstand the demands of heavy-duty applications.

QST30 Series

The QST30 CM2350 T101 and QST30 CM552 engines are designed to work with the Clevis Pin 3086252. This compatibility ensures that the linkage systems in these engines function optimally, contributing to the overall efficiency and performance of the engine.

By ensuring that the Clevis Pin 3086252 is used with the appropriate engine models, maintenance and repair processes can be carried out with confidence, knowing that the part is specifically designed to fit and perform in these engines.

Role of Part 3086252 Clevis Pin in Engine Systems

The 3086252 Clevis Pin is an integral component in various engine systems, facilitating the secure connection and efficient operation of several key assemblies.

In the Belt Tensioner system, the Clevis Pin ensures the proper alignment and tension of the belt, which is essential for the transfer of power to auxiliary components such as the alternator and water pump. Its role here is to maintain consistent belt tension, reducing wear and ensuring reliable operation.

Within the Drive System, the Clevis Pin is utilized to connect different drive components, allowing for the smooth transmission of rotational force. This is particularly important in applications where precise movement and minimal slippage are required.

The Fan and Fan Drive assemblies benefit from the Clevis Pin by ensuring that the fan blades are securely attached to the drive mechanism. This connection is vital for effective engine cooling, as it allows the fan to operate at the correct speed and angle.

In the Fan Drive Idle Assembly and Fan Drive Idler Assembly, the Clevis Pin plays a part in maintaining the structural integrity and operational efficiency of these components. It helps in the smooth rotation and adjustment of the idler pulleys, which are crucial for managing the belt’s path and tension during operation.

For Mounting purposes, the Clevis Pin is often used to secure various engine components to the engine block or chassis. This ensures that these parts remain in the correct position and orientation, contributing to the overall stability and performance of the engine.

Overall, the 3086252 Clevis Pin is a versatile and essential component in engine systems, providing the necessary connections and adjustments that enable these systems to function efficiently and reliably.

Conclusion

The Cummins 3086252 Clevis Pin is a critical component in the operation and maintenance of commercial trucks and Cummins engines. Its role in ensuring secure connections and efficient operation of various engine systems cannot be overstated. Proper installation, regular maintenance, and adherence to safety protocols are essential to maximize the performance and longevity of this part. By understanding its purpose, features, and benefits, truck operators and maintenance personnel can ensure optimal truck performance and safety.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.