This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

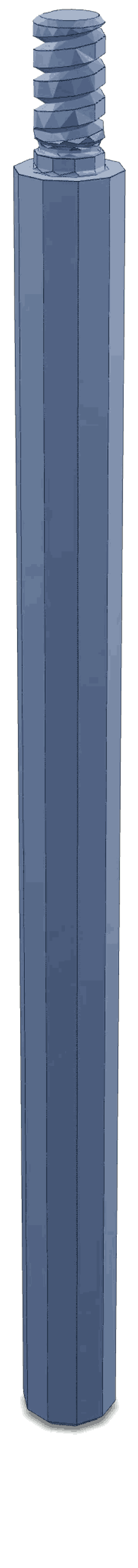

Connecting rod guide pins are essential components in heavy-duty truck engines, ensuring the smooth operation of the engine’s moving parts. This article delves into the 3163097 Connecting Rod Guide Pin by Cummins, examining its role and significance within the engine system.

Basic Concepts

Connecting rod guide pins are critical elements in the engine, primarily responsible for maintaining the alignment of the connecting rod as it moves in relation to the crankshaft. These pins interact closely with the connecting rod and crankshaft, ensuring that the motion between these components is precise and friction-reduced. The guide pin’s role is to support the connecting rod’s small end, allowing it to pivot smoothly around the crankshaft journal 1.

Role and Function

The 3163097 Connecting Rod Guide Pin by Cummins is designed to maintain the alignment of the connecting rod, which is vital for the efficient transfer of power from the piston to the crankshaft. By ensuring proper alignment, the guide pin helps in reducing friction and wear on the connecting rod and crankshaft surfaces. This contributes to the overall efficiency and longevity of the engine 2.

Key Features

This Cummins part is engineered with specific design and material characteristics to enhance its durability and performance. Crafted from high-quality materials, it is designed to withstand the high stresses and temperatures encountered within a heavy-duty engine. Its precise manufacturing ensures a snug fit within the connecting rod and crankshaft, minimizing play and maximizing efficiency 3.

Benefits

The use of the 3163097 offers several advantages. It contributes to improved engine efficiency by ensuring smooth and precise motion between the connecting rod and crankshaft. Additionally, by reducing friction and wear, it enhances the reliability and longevity of the engine components. The guide pin’s design also aids in maintaining optimal engine performance under varying load conditions.

Troubleshooting and Maintenance

Identifying issues with connecting rod guide pins is important for maintaining engine health. Common problems may include excessive wear, misalignment, or damage to the pin or its surrounding components. Regular maintenance checks are recommended to ensure the guide pin and related parts are in good condition. If issues are detected, prompt replacement or repair is advised to prevent further engine damage.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines and related components. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industries. The company’s commitment to excellence is reflected in its products, including the 3163097.

Conclusion

The 3163097 Connecting Rod Guide Pin by Cummins plays a significant role in the operation and efficiency of heavy-duty truck engines. Its design and material characteristics ensure durability and performance, contributing to the overall reliability and longevity of the engine. Regular maintenance and prompt attention to any issues are crucial for maintaining engine health and performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.