This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

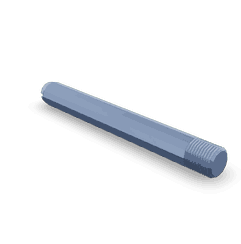

The Guide Pin 3163934, manufactured by Cummins, is a critical component in the commercial truck industry. This part is designed to ensure the smooth operation of various mechanical systems in commercial trucks.

Basic Concepts of Guide Pins

Guide pins serve as mechanical components that align and guide moving parts within a system. They provide a stable reference point for other components to move against or along. Precision in manufacturing is essential, as even minor deviations can lead to misalignment and mechanical issues. Typically, guide pins are made from materials like steel or stainless steel, chosen for their durability and resistance to wear. The material selection and manufacturing precision contribute to the reliability and longevity of the guide pin in its application 1.

Role of Guide Pin 3163934 in Truck Operation

This Cummins part is integral to the operation of commercial trucks. It interacts with various systems and components, ensuring smooth and precise movements. The Guide Pin 3163934 maintains proper alignment and facilitates the intended motion of parts within the system, contributing to the overall functionality and efficiency of the truck. Its role is particularly important in systems where precise movement and alignment are necessary for optimal performance 2.

Key Features of Guide Pin 3163934

The Guide Pin 3163934 is distinguished by several key features. Its design is tailored to meet the specific demands of commercial truck applications, ensuring compatibility and performance. The material used in its construction is selected for its strength and resistance to the operational stresses encountered in truck systems. Additionally, its dimensions are precisely engineered to fit within the designated systems, ensuring both functionality and durability. Unique characteristics may include surface treatments that enhance wear resistance or specific geometries that improve alignment and reduce friction 3.

Benefits of Using Guide Pin 3163934

Incorporating this part into truck systems offers several advantages. These include improved efficiency through precise alignment and movement, enhanced durability due to the material and construction quality, and ease of maintenance facilitated by its design. The guide pin’s ability to withstand operational stresses contributes to the reliability and longevity of the truck’s mechanical systems 4.

Troubleshooting and Maintenance

To ensure the longevity and optimal performance of the Guide Pin 3163934, regular inspections and maintenance are recommended. Common issues may include wear, misalignment, or damage due to operational stresses. Troubleshooting methods involve checking for signs of wear or damage, ensuring proper alignment, and addressing any issues promptly. Maintenance practices include cleaning the guide pin and its surrounding components to prevent buildup that could affect performance. Replacement should be considered if significant wear or damage is detected, ensuring the continued smooth operation of the truck’s systems.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and customer satisfaction in the commercial truck industry. The company’s commitment to these values is reflected in its product range, which is designed to meet the demanding requirements of commercial applications.

Conclusion

The Guide Pin 3163934 by Cummins plays a vital role in the efficient and reliable operation of commercial trucks. Its precise design, durable construction, and ease of maintenance make it an essential component for ensuring the smooth functioning of truck systems. Regular maintenance and prompt troubleshooting are key to maximizing the lifespan and performance of this part.

-

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩ -

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩ -

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.