This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3376020 Holding Pin is a specialized component designed for use in commercial trucks. It plays a significant role in the secure operation and maintenance of these vehicles. Understanding its purpose and significance is fundamental for ensuring the efficient and safe functioning of heavy-duty trucks.

Basic Concepts of Holding Pins

Holding pins are mechanical devices used across various machinery to secure components in place. In the context of heavy-duty trucks, these pins are vital for maintaining the integrity of the vehicle’s structure during operation and facilitating safe and efficient maintenance procedures. They prevent components from shifting or dislodging, which could lead to operational inefficiencies or safety hazards 1.

Purpose of the Cummins 3376020 Holding Pin

The Cummins 3376020 Holding Pin is specifically engineered to secure components within the truck’s engine or transmission system. Its role is to hold parts in position during maintenance operations or while the truck is in use, ensuring that all components remain aligned and function as intended. This contributes to the overall stability and performance of the vehicle 2.

Key Features

This part boasts several key features that enhance its functionality. It is constructed from high-strength materials, ensuring durability under the demanding conditions of commercial truck operation. Its design includes precise dimensions and a secure fitting mechanism, which allows it to effectively hold components in place without the risk of slippage or failure 3.

Benefits of Using the Cummins 3376020 Holding Pin

Utilizing this Cummins part offers several advantages. It enhances safety by securely holding components, reducing the risk of accidents during maintenance or operation. It also improves efficiency in maintenance procedures by providing a reliable means to keep parts in place, allowing for quicker and more straightforward repairs. Additionally, its robust design ensures reliability, contributing to the consistent performance of the truck 4.

Installation Process

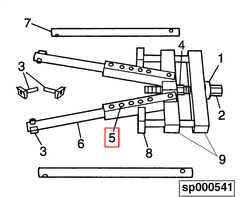

Installing the 3376020 requires careful attention to detail. The process involves identifying the correct location for the pin, ensuring the area is clean and free from debris, and then inserting the pin until it is securely in place. It is important to follow manufacturer guidelines to avoid common pitfalls such as incorrect placement or over-tightening, which could damage the pin or the components it is securing.

Troubleshooting Common Issues

Frequent problems with holding pins can include difficulty in insertion, slippage, or damage to the pin. These issues may arise from incorrect installation, wear and tear, or exposure to extreme conditions. Solutions involve re-evaluating the installation process, replacing worn or damaged pins, and ensuring that all components are compatible and correctly aligned.

Maintenance Tips

Regular maintenance of the 3376020 Holding Pin is vital for its longevity and performance. This includes routine inspections for signs of wear or damage, cleaning the pin and its surrounding area to prevent corrosion, and ensuring that it remains securely in place. Adhering to these practices helps maintain the pin’s effectiveness and contributes to the overall reliability of the truck.

Safety Considerations

When working with the 3376020 Holding Pin, it is important to observe safety protocols to prevent accidents. This includes wearing appropriate personal protective equipment, ensuring the truck is securely parked and the engine is off before beginning any maintenance, and following all manufacturer guidelines for installation and use. These precautions help ensure the safety of the individual performing the maintenance and the longevity of the vehicle’s components.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and a broad product range, Cummins is renowned for its quality and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its products, including the 3376020 Holding Pin, which is designed to meet the high standards of performance and durability expected in commercial applications.

Conclusion

The Cummins 3376020 Holding Pin is a critical component in the maintenance and operation of commercial trucks. Its design and features ensure the secure positioning of components, contributing to the safety, efficiency, and reliability of heavy-duty vehicles. Regular maintenance and adherence to safety protocols are essential for maximizing the performance and longevity of this part.

-

Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Modern Automotive Electrical Systems (Wiley, 2022).

↩ -

Nicholas Goodnight and Kirk Van Gelder, Automotive Braking Systems (Jones & Bartlett Learning, 2018).

↩ -

John Dixon, Modern Diesel Technology Preventive Maintenance and Inspection (Delmar Cengage Learning, 2010).

↩ -

John Kasab and Andrea Strzelec, Automotive Emissions Regulations and Exhaust Aftertreatment Systems (SAE International, 2020).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.