This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

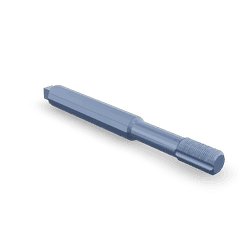

The Cummins 3376205 Tapping is a specialized component designed for use in heavy-duty truck engines. Its purpose is to facilitate specific functions within the engine’s system, contributing to the overall performance and reliability of the engine. Understanding the role and significance of this part is important for maintaining and optimizing the operation of heavy-duty trucks.

Basic Concepts of Tapping

Tapping, in the context of engine components, refers to the process of creating threaded holes in metal parts to allow for the secure attachment of other components. This technique is crucial for assembling various engine parts, ensuring they are held firmly in place under the high stresses and temperatures encountered in engine operation. Tapping plays a role in the structural integrity and functional efficiency of engine components by providing a means to connect parts that require precise alignment and secure fastening 1.

Purpose of the 3376205 Tapping

The 3376205 Tapping is specifically designed to play a role in the fuel system of truck engines. It functions as a component that allows for the secure attachment of fuel lines or other related parts to the engine block or fuel system components. By providing a threaded interface, it ensures that connections are tight and leak-free, which is important for the efficient operation of the fuel system and the overall performance of the engine 2.

Key Features

The 3376205 Tapping is characterized by its precise threading, which is designed to match the specifications required for its application in heavy-duty truck engines. It is typically made from high-strength materials to withstand the pressures and temperatures within the engine environment. Its design may include features such as a tapered thread for a secure fit or a specific thread pitch to accommodate the fuel system components it connects.

Benefits

The use of the 3376205 Tapping offers several advantages, including improved engine performance through secure and leak-free connections in the fuel system. Its durable construction contributes to the longevity of the engine components it connects, reducing the need for frequent replacements or repairs. Additionally, the precise threading ensures that connections are made correctly the first time, saving time during engine assembly or maintenance 3.

Installation Process

Installing the 3376205 Tapping requires careful attention to ensure a proper fit and secure connection. The process involves cleaning the installation area to remove any debris that could affect the seal, applying the appropriate thread sealant to prevent leaks, and using the correct tools to tighten the tapping to the specified torque. It is important to follow manufacturer guidelines to ensure the tapping is installed correctly and functions as intended within the engine system.

Common Issues and Troubleshooting

Common issues with the 3376205 Tapping may include leaks at the connection point, which can be caused by improper installation, damage to the threading, or the use of incompatible components. Troubleshooting steps may involve inspecting the threading for damage, ensuring the correct torque was used during installation, and verifying that all components are compatible. In some cases, replacing the tapping or the connected components may be necessary to resolve the issue.

Maintenance Tips

Regular maintenance of the 3376205 Tapping involves inspecting the connection for signs of leaks or wear and ensuring that all connections are secure. It is also important to follow the manufacturer’s recommendations for periodic checks and any necessary adjustments or replacements. Keeping the area around the tapping clean and free of debris can help prevent issues and ensure the longevity of the component.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins plays a significant role in the diesel engine industry, providing components and systems that are known for their reliability and performance. The company’s commitment to excellence is reflected in its wide range of products, which are used in various applications, from heavy-duty trucks to industrial and marine engines.

Role of Part 3376205 Tapping in Engine Systems

Part 3376205, a Tapping component, is integral to the functionality of various engine systems. Its primary role is to facilitate the tapping process, which is essential for the installation and removal of threaded components within the engine.

In the context of a Thread Salvage Kit, the Tapping component ensures that threads are properly formed or restored. This is particularly important when dealing with damaged or worn threads in engine blocks, cylinder heads, or other critical components. By using the Tapping component, mechanics can accurately cut new threads or repair existing ones, ensuring a secure fit for fasteners and other threaded parts. This process helps maintain the integrity of the engine’s structure and prevents leaks or failures that could arise from improperly threaded components.

Additionally, the Tapping component is used in conjunction with other tools within the Thread Salvage Kit to assess thread damage, select the appropriate tap size, and execute the tapping procedure with precision. This meticulous approach is vital for the longevity and performance of the engine, as it ensures that all threaded connections are robust and reliable.

Conclusion

The Cummins 3376205 Tapping is a critical component in the maintenance and optimization of heavy-duty truck engines. Its role in facilitating secure and leak-free connections within the fuel system underscores its importance in engine performance and reliability. Proper installation, maintenance, and troubleshooting of this part are essential for ensuring the longevity and efficiency of the engine. Cummins’ commitment to quality and innovation is evident in the design and functionality of this component, making it a valuable asset in the diesel engine industry.

-

Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Modern Automotive Electrical Systems (Wiley, 2022).

↩ -

Joseph A Bell, Modern Diesel Technology Electricity Electronics (Delmar Cengage Learning, 2014).

↩ -

Pawel Drozdziel, The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects (Routledge, 2023).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.