This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3393562 Straight Pin is a specialized component designed for use in commercial truck operations. Its purpose is to provide secure and reliable connections within the truck’s mechanical systems, ensuring efficient and safe operation. This straight pin is integral to maintaining the structural integrity and functionality of various truck components.

Basic Concepts of Straight Pins

Straight pins are cylindrical fasteners used to join two or more components together. They are commonly employed in mechanical systems to ensure that parts remain aligned and securely connected. Straight pins function by being inserted into pre-drilled holes, creating a fixed connection that resists movement and wear. Their simplicity and effectiveness make them a staple in various mechanical applications 1.

Purpose and Role in Truck Operation

The Cummins 3393562 Straight Pin serves a specific purpose in truck mechanics by securing components that require precise alignment and minimal movement. It plays a role in maintaining the integrity of connections within the truck’s mechanical system, which is vital for the overall functionality and performance of the vehicle. By ensuring that parts remain correctly positioned, this straight pin contributes to the smooth operation and reliability of the truck 2.

Key Features

The Cummins 3393562 Straight Pin is characterized by several key features that enhance its performance and durability. It is typically made from high-quality materials such as hardened steel, which provides strength and resistance to wear. The dimensions of the pin are precisely engineered to fit specific applications, ensuring a secure and stable connection. Additionally, the design may include features such as chamfered ends to facilitate easy insertion and reduce the risk of damage during installation 3.

Benefits

The Cummins 3393562 Straight Pin offers several benefits that contribute to improved mechanical stability and performance. Its robust material composition ensures longevity, even in harsh operating conditions. The precise dimensions and secure fit help maintain alignment and reduce the risk of component failure. Furthermore, the durability of the pin enhances the overall reliability of the truck’s mechanical system 4.

Installation and Usage

Proper installation of the Cummins 3393562 Straight Pin is crucial for ensuring its correct function within the truck’s mechanical system. The installation process involves carefully aligning the pin with the pre-drilled holes in the components it connects. It is important to use the appropriate tools to insert the pin without causing damage. Best practices include verifying the alignment of connected parts and ensuring that the pin is fully seated to achieve a secure connection.

Troubleshooting and Maintenance

Common issues associated with straight pins include misalignment, wear, and damage from improper installation. Regular inspection of the pins can help identify these issues early. Maintenance tips for the Cummins 3393562 Straight Pin include checking for signs of wear or damage, ensuring that connected parts remain aligned, and replacing the pin if necessary to maintain reliable performance. Proper lubrication of surrounding components can also contribute to the longevity of the pin.

Safety Considerations

When handling and installing the Cummins 3393562 Straight Pin, it is important to follow safety guidelines to avoid common pitfalls and ensure safe operation. This includes wearing appropriate personal protective equipment (PPE) such as gloves and safety glasses. Careful handling of the pin during installation helps prevent injury and damage to the component. Additionally, ensuring that all tools and equipment are in good working condition contributes to a safe working environment.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the commercial truck industry. Founded in 1919, Cummins has a history of innovation and quality in the production of automotive components. The company is committed to delivering reliable and high-performance parts that meet the demanding requirements of commercial truck operations. Cummins’ dedication to quality and continuous improvement ensures that their products, including the Cummins 3393562 Straight Pin, are trusted by professionals in the industry.

Compatibility of Straight Pin Part 3393562 with Cummins Engines

The Straight Pin part number 3393562, manufactured by Cummins, is designed to fit seamlessly within a variety of Cummins engine models. This part is integral to the engine’s operation, ensuring proper alignment and functionality of various components.

QSK45 CM500 and QSK60 CM500

The Straight Pin part 3393562 is compatible with both the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their robust performance and reliability in heavy-duty applications. The pin’s design ensures it fits perfectly within the specified tolerances of these engines, maintaining the integrity of the engine’s internal mechanisms.

QSK60 CM850 MCRS, QSK60G, and QSK78 CM500

The engines QSK60 CM850 MCRS, QSK60G, and QSK78 CM500 also accommodate the Straight Pin part 3393562. These engines are part of the QSK series, which is designed for high-performance applications. The pin’s precision engineering guarantees a snug fit, contributing to the overall efficiency and longevity of these engines.

QSK95 CM2350 K111 and QSK95 CM2350 K113

The Straight Pin part 3393562 is also suitable for the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines. These engines are part of the QSK95 series, which is known for its exceptional power and reliability. The pin’s design ensures it integrates smoothly with the engine’s components, providing the necessary support and stability.

In summary, the Straight Pin part 3393562 is a versatile component that fits a range of Cummins engines, ensuring optimal performance and durability across different models.

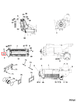

Role of Part 3393562 Straight Pin in Engine Systems

The part 3393562 Straight Pin is integral to the efficient operation of various engine components. In the Distributor Kit, this straight pin ensures the precise alignment and secure fitting of components, which is essential for the accurate distribution of electrical impulses to the spark plugs.

Within the Filter systems, particularly the Full Flow Oil Filter and Lubricating Oil Filter, the straight pin plays a role in maintaining the structural integrity of the filter assembly. It helps in the proper seating of the filter elements, ensuring that oil flows through the filter media as designed, which is vital for effective filtration and the removal of contaminants from the lubricating oil.

In the Lubricating Oil Filter Head and Lubricating Oil Filter Kit, the straight pin is used to secure components in place, facilitating a leak-proof seal between the filter head and the engine block. This is important for maintaining the pressure within the lubrication system, which is necessary for optimal oil circulation and engine protection.

Overall, the part 3393562 Straight Pin contributes to the reliability and performance of these engine components by ensuring proper assembly, alignment, and sealing, which are fundamental to the efficient operation of the engine’s lubrication and ignition systems.

Conclusion

The Cummins 3393562 Straight Pin is a critical component in the operation of commercial trucks and Cummins engines. Its design and material composition ensure durability and reliable performance in various mechanical systems. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this part. Cummins’ commitment to quality and innovation ensures that the 3393562 Straight Pin remains a trusted component in the industry.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013

↩ -

Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves, Angelina Eret, Springer Nature, 2024

↩ -

Advanced Hybrid Powertrains for Commercial Vehicles Second Edition, Haoran Hu, Simon J Baseley and Xubin Song, SAE International, 2021

↩ -

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.