This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

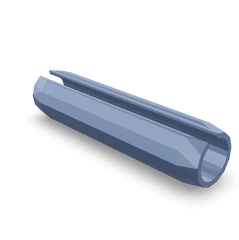

The Cummins 3522597 Roll Pin is a specialized component designed for use in heavy-duty trucks. It serves a significant role in mechanical assemblies by ensuring the proper alignment and secure fastening of various components. Understanding its function and importance is key to maintaining the efficiency and reliability of heavy-duty truck engines.

Basic Concepts of Roll Pins

Roll pins are cylindrical fasteners used in mechanical systems to align and secure components without the need for additional fasteners like screws or bolts. They function by being pressed into pre-drilled holes, expanding slightly to create a tight fit. In the automotive industry, roll pins are commonly used in applications where components need to be held in precise alignment, such as in gear assemblies, engine components, and transmission systems 1.

Purpose of the Cummins 3522597 Roll Pin

The Cummins 3522597 Roll Pin is specifically designed to play a role in the operation of heavy-duty trucks by aligning and securing components within the engine system. Its function is to ensure that parts such as gears, shafts, and other rotating components remain in the correct position, which is vital for the smooth operation of the engine. By providing a secure and stable connection, the roll pin contributes to the overall efficiency and durability of the truck’s engine.

Key Features

The Cummins 3522597 Roll Pin is characterized by its precise design and material composition. It is typically made from high-quality steel, which provides the necessary strength and durability for heavy-duty applications. The roll pin’s dimensions are carefully engineered to ensure a snug fit within the pre-drilled holes, enhancing its performance and reliability. Additionally, its design may include features such as a slightly larger diameter at the ends to prevent it from being pulled out of place.

Benefits of Using Roll Pins

Roll pins offer several advantages in mechanical systems. They provide improved alignment of components, which is crucial for the proper functioning of engine parts. Additionally, roll pins reduce friction between moving parts, leading to smoother operation and less wear over time. Their design also contributes to enhanced durability, making them a reliable choice for heavy-duty applications 2.

Installation and Usage

Proper installation of the Cummins 3522597 Roll Pin is important to ensure optimal performance and longevity. It should be pressed into place using appropriate tools to achieve the correct fit without damaging the component or the surrounding parts. Following manufacturer guidelines for installation procedures will help maintain the integrity of the roll pin and the components it secures.

Troubleshooting Common Issues

Common issues associated with roll pins include misalignment and wear. Misalignment can occur if the roll pin is not properly installed, leading to improper component function. Wear may result from excessive use or improper material selection. Troubleshooting these issues involves inspecting the roll pin and surrounding components for signs of damage or misalignment and replacing the roll pin if necessary.

Maintenance Tips

Regular maintenance of roll pins is important to prevent failures and ensure continued reliable operation. This includes periodic inspection for signs of wear or damage and replacing the roll pin as needed. Adhering to recommended inspection intervals and replacement guidelines will help maintain the efficiency and reliability of the engine system.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a strong reputation in the automotive and heavy-duty truck industries, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and history of excellence make it a trusted name in the industry.

Cummins Engine Part 3522597 Roll Pin Compatibility

The Cummins part 3522597, a Roll Pin, is a crucial component in the assembly and operation of various Cummins engines. This roll pin is designed to provide stability and alignment in the engine’s moving parts, ensuring smooth and efficient performance. Below is a detailed breakdown of the engines with which this roll pin is compatible.

Compatible Engines

- 15N CM2380 M104B

- 4B3.9

- 6B5.9

- 6C8.3

- B3.3

- B4.5

- B4.5 CM2350 B129B

- B5.6 CM2670 B152B

- B5.9 CM2670 B166C

- B5.9 G

- B5.9 GAS PLUS CM556

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- B6.7 G CMOH6.0 B125

- B6.7S

- C GAS PLUS CM556

- C8.3 G

- D4.0 CM2620 D103B

- F2.8 CM2620 F135B

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- F3.8 F102

- F4.5 CM2620 F139B

Grouping of Compatible Engines

The Cummins part 3522597 Roll Pin is compatible with a diverse range of engine models, which can be grouped based on their specifications and applications:

Group 1: Smaller Displacement Engines

- 4B3.9

- 6B5.9

- B3.3

- B4.5

- B4.5 CM2350 B129B

- F2.8 CM2620 F135B

- F3.8 F102

Group 2: Medium Displacement Engines

- 6C8.3

- B5.6 CM2670 B152B

- B5.9 CM2670 B166C

- B5.9 G

- B5.9 GAS PLUS CM556

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

Group 3: Larger Displacement Engines

- 15N CM2380 M104B

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- B6.7 G CMOH6.0 B125

- B6.7S

- C GAS PLUS CM556

- C8.3 G

- D4.0 CM2620 D103B

This detailed compatibility information ensures that technicians and engine users can confidently select the appropriate roll pin for their specific Cummins engine model.

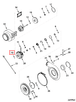

Role of Part 3522597 Roll Pin in Engine Systems

The 3522597 Roll Pin is an integral component in various engine systems, ensuring smooth operation and efficient performance. In the Aftercooler and Aftercooler Plumbing, the roll pin secures connections and supports, maintaining the integrity of the cooling system which is vital for optimal engine performance.

Within the Cam Follower Shaft Support, the roll pin facilitates the precise movement of the cam follower, ensuring accurate valve timing and efficient engine operation.

In the Connecting Rod and Piston assembly, the roll pin plays a key role in maintaining the alignment and stability of the connecting rod, which is essential for the smooth translation of piston movement to crankshaft rotation.

For the Core Assembly Heat Exchanger35, Core Assembly Heat Exchanger35M, Core Assembly Heat Exchanger50M, and Core Assembly Heat Exchanger551W, the roll pin ensures that the components are securely fastened, allowing for efficient heat exchange and maintaining the engine’s thermal management.

In the Emissions Rebuild Kit and Engine Installation Kit, the roll pin is used to secure various components, ensuring that the engine is installed correctly and that emission standards are met.

The Engine Piston and Engine Piston Kit rely on the roll pin to maintain the structural integrity of the piston components, ensuring reliable engine performance.

In the Exhaust Gas Collector Housing, the roll pin helps in securing the housing, which is essential for efficient exhaust gas management.

The Fuel Pump Coupling utilizes the roll pin to ensure a secure connection between the fuel pump and the engine, which is critical for consistent fuel delivery.

In the Kit Turbocharger Repair and Kit Turbo T18A KV16, the roll pin is essential for maintaining the structural integrity of the turbocharger components, ensuring efficient air compression and engine performance.

The Oil Connection components rely on the roll pin to ensure secure and leak-free connections, which is vital for maintaining proper lubrication within the engine.

The Overhaul Kit includes the roll pin to ensure that all components are securely fastened during engine overhaul, contributing to the engine’s longevity and performance.

In Performance Parts and Power Turbine assemblies, the roll pin ensures that all moving parts are aligned and secured, which is essential for maximizing engine power and efficiency.

The Short Engine Kit and Turbine Housing also utilize the roll pin to secure components, ensuring that the engine operates smoothly and efficiently.

Lastly, in Turbocharger Aftermarket and Turbocharger T18-A Kit applications, the roll pin is crucial for maintaining the structural integrity of the turbocharger, ensuring reliable and efficient engine performance.

Conclusion

The Cummins 3522597 Roll Pin is a critical component in the maintenance and operation of heavy-duty truck engines. Its role in aligning and securing various engine components ensures the smooth and efficient performance of the engine. Proper installation, regular maintenance, and understanding its compatibility with different Cummins engine models are essential for maximizing the efficiency and reliability of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.