This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3680698 Cotter Pin by Cummins is a specialized fastener designed for use in commercial truck maintenance and operation. This component plays a role in securing various parts within the truck’s mechanical systems, ensuring they remain in place under operational stress. Its significance lies in contributing to the overall reliability and safety of the vehicle.

Basic Concepts of Cotter Pins

A cotter pin is a simple yet effective fastener used in mechanical systems to secure components that are subject to vibration or rotational forces. It consists of a metal pin with a bent end, which is inserted through a hole in the components to be joined. Once in place, the bent end is folded back to prevent the pin from coming out, thereby locking the components together. This mechanism is widely used in various industries for its simplicity and effectiveness in securing parts 1.

Purpose of Cotter Pin 3680698 in Truck Operation

The 3680698 Cotter Pin by Cummins is specifically designed to play a role in the operation of commercial trucks. It is commonly used in systems where components are subject to significant stress or movement, such as in the fastening of castle nuts on kingpin axes, brake components, and other critical parts. By securing these components, the cotter pin helps maintain the integrity and functionality of the truck’s mechanical systems.

Key Features of Cotter Pin 3680698

The 3680698 Cotter Pin is characterized by its robust design and high-quality material, typically made from hardened steel to ensure durability and resistance to wear. Its precise dimensions and bent end design are tailored to provide a secure fit in the applications it is intended for. These features contribute to its reliability and effectiveness in commercial truck environments.

Benefits of Using Cotter Pin 3680698

Utilizing the 3680698 Cotter Pin offers several advantages. It provides a secure fastening solution that resists loosening due to vibration or rotational forces. The ease of installation and removal makes it a convenient choice for maintenance tasks. Additionally, its reliability under stress ensures that critical components remain securely fastened, contributing to the safety and efficiency of truck operations.

Installation and Usage Guidelines

Proper installation of the 3680698 Cotter Pin involves inserting the pin through the hole in the components to be joined, ensuring it aligns with the slot in the castle nut or similar fastener. The bent end is then folded back to secure the components together. Tools required may include pliers for bending the pin end. It is important to ensure the pin is properly seated and the bent end is securely folded to prevent loosening.

Troubleshooting Common Issues

Common issues with cotter pins include corrosion, which can weaken the pin, and improper fit, which may lead to loosening. Regular inspection for signs of corrosion and ensuring the pin is the correct size for the application can help prevent these issues. In cases of corrosion, replacing the pin is recommended. For improper fit, selecting the correct size pin or adjusting the components may be necessary.

Maintenance Tips

Regular inspection of the 3680698 Cotter Pin is recommended to ensure its ongoing functionality and safety. Check for signs of wear, corrosion, or loosening, and replace the pin as needed. Keeping the pin and surrounding components clean and free of debris can also help maintain its effectiveness. Following these maintenance practices can contribute to the longevity and reliability of the fastening solution.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and customer satisfaction in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle applications 2.

Compatibility of Cotter Pin 3680698 with Cummins Engines

The 3680698 Cotter Pin, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This part is integral in securing various components within the engine, ensuring that they remain in place and function correctly.

ISX Series Engines

- ISX CM570

- ISX CM870

- ISX CM871

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

The ISX series engines, including the ISX CM570, ISX CM870, ISX CM871, ISX15 CM2250, ISX15 CM2250 SN, and ISX15 CM2350 X101, all utilize the 3680698 Cotter Pin. This part is crucial in maintaining the alignment and stability of certain engine components, ensuring optimal performance and longevity of the engine.

QSX Series Engines

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

The QSX15 CM2250, QSX15 CM2250 ECF, and QSX15 CM2350 X105 engines also incorporate the 3680698 Cotter Pin. This part plays a vital role in securing specific parts within these engines, contributing to the overall reliability and efficiency of the engine’s operation.

X15 Series Engines

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

The X15 series engines, including the X15 CM2350 X116B, X15 CM2350 X123B, and X15 CM2450 X134B, are also compatible with the 3680698 Cotter Pin. This part is essential for maintaining the integrity of various engine components, ensuring that the engine operates smoothly and efficiently.

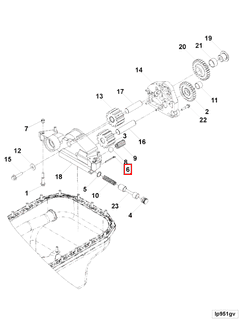

Role of Part 3680698 Cotter Pin in Engine Systems

The 3680698 Cotter Pin is instrumental in ensuring the secure assembly and reliable operation of various engine components. In the context of the lubricating oil pump, this Cotter Pin is utilized to fasten components such as the pump shaft and housing, ensuring that they remain aligned and do not shift during operation. This alignment is essential for the efficient transfer of lubricating oil throughout the engine, maintaining optimal lubrication of moving parts and reducing wear 3.

Within the lubricating pump kit, the Cotter Pin plays a similar role, securing the pump’s internal components to prevent any misalignment that could lead to inefficiencies or failures. Its application in the overhaul kit ensures that during maintenance or repair processes, the reassembled components are held firmly in place, contributing to the longevity and performance of the pump.

In broader pump applications, the Cotter Pin is used to secure gears, shafts, and other rotating elements, ensuring smooth operation and preventing undue stress on the pump’s bearings and seals. This is particularly important in high-pressure environments where even minor misalignments can lead to significant performance issues.

For the lubricating oil system as a whole, the secure fastening provided by the Cotter Pin is vital. It ensures that the oil is delivered consistently and under the correct pressure to all parts of the engine, facilitating smooth operation, reducing friction, and enhancing the engine’s overall efficiency and lifespan.

Conclusion

The 3680698 Cotter Pin by Cummins is a critical component in the maintenance and operation of commercial trucks and engines. Its robust design, ease of use, and compatibility with a wide range of Cummins engines make it an essential part for ensuring the reliability and safety of vehicle operations. Regular maintenance and proper installation are key to maximizing the effectiveness of this part in securing critical components and contributing to the overall performance of the vehicle.

-

Garrett, TK, Newton, K, Steeds, W. The Motor Vehicle. Reed Educational and Professional Publishing Ltd, 2001.

↩ -

Zhao, Hua. Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press, 2010.

↩ -

Reif, Konrad. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.