This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3756135 Roll Pin is a specialized component designed for use in heavy-duty truck applications. Its purpose is to secure various engine components in place, ensuring the smooth operation and reliability of the truck’s engine system. Given the demanding conditions under which heavy-duty trucks operate, the role of the Cummins 3756135 Roll Pin is significant in maintaining the integrity and performance of critical assemblies.

Basic Concepts of Roll Pins

Roll pins are cylindrical fasteners used in mechanical systems to hold components together. They function by being pressed into pre-drilled holes, where they expand slightly to create a secure fit. This method of fastening is particularly useful in applications where traditional screws or bolts may not provide sufficient stability or where space constraints are a concern. Roll pins are commonly used in engines, transmissions, and other mechanical assemblies to ensure components remain aligned and securely in place 1.

Purpose of the Cummins 3756135 Roll Pin

The Cummins 3756135 Roll Pin plays a specific role in the operation of heavy-duty trucks by securing engine components such as bearings, gears, and other critical parts. Its application ensures that these components remain properly aligned and do not shift during operation, which is vital for the engine’s efficiency and longevity. By maintaining the precise positioning of these parts, the roll pin contributes to the overall reliability and performance of the truck’s engine 2.

Key Features

The Cummins 3756135 Roll Pin is characterized by several key features that enhance its performance and durability. It is typically made from high-quality steel, which provides the necessary strength and resistance to wear. The dimensions of the roll pin are precisely engineered to fit specific applications, ensuring a secure and stable connection. Additionally, its design includes features that facilitate easy installation and removal, making it a practical choice for maintenance and repair tasks 3.

Benefits

Using the Cummins 3756135 Roll Pin offers several benefits in heavy-duty truck applications. Its robust construction and precise fit contribute to improved reliability and performance of the engine components it secures. The roll pin’s durability ensures longevity, reducing the need for frequent replacements and maintenance. Furthermore, its design allows for efficient installation, minimizing downtime during repairs and maintenance procedures.

Installation Process

Proper installation of the Cummins 3756135 Roll Pin is crucial for ensuring its effectiveness and the reliability of the engine components it secures. The installation process involves pressing the roll pin into a pre-drilled hole using a suitable tool. It is important to ensure that the hole is clean and free of debris to allow for a secure fit. Additionally, the roll pin should be installed with the correct amount of force to achieve the desired expansion without causing damage to the surrounding components. Following manufacturer guidelines and best practices during installation will help avoid common pitfalls and ensure optimal performance.

Troubleshooting Common Issues

Common issues associated with roll pins in truck applications include misalignment, wear, and damage due to improper installation. To troubleshoot these problems, it is important to conduct a thorough inspection of the roll pin and the components it secures. Signs of wear or damage may indicate the need for replacement. Additionally, ensuring that the roll pin is correctly installed and that the surrounding components are properly aligned can help prevent future issues. Regular maintenance and inspection routines can also aid in identifying and addressing potential problems before they lead to more significant issues.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3756135 Roll Pin, regular maintenance is recommended. This includes periodic inspection of the roll pin and the components it secures to check for signs of wear, damage, or misalignment. Cleaning the roll pin and its surrounding areas can prevent debris from affecting its performance. Additionally, following recommended service intervals for engine maintenance can help identify and address any issues related to the roll pin before they become critical. Proper care and maintenance will contribute to the overall reliability and efficiency of the truck’s engine system.

Cummins Overview

Cummins Inc. is a renowned manufacturer of diesel engines and related components, with a strong reputation in the commercial truck industry. Founded in 1919, Cummins has a long history of innovation and excellence in engine technology. The company is known for producing high-quality, reliable components that meet the demanding requirements of heavy-duty truck applications. Cummins’ commitment to quality and performance has established it as a leading provider of diesel engine solutions for the commercial transportation sector.

Cummins Engine Part 3756135 Roll Pin Compatibility

The Cummins part 3756135 Roll Pin is a critical component that ensures the proper functioning of various engine systems. This roll pin is designed to fit seamlessly into multiple engine models, providing stability and alignment where needed. Below is a detailed overview of the engines that are compatible with this part.

ISX Series Engines

- ISX CM570

- ISX CM870

- ISX15 CM2250 SN

The ISX series engines, including the CM570, CM870, and the larger ISX15 CM2250 SN, are known for their robust performance and reliability. The roll pin 3756135 is integral to these engines, ensuring that moving parts remain aligned and secure during operation.

K Series Engines

- K19

- K38

The K series engines, specifically the K19 and K38, are designed for heavy-duty applications. The roll pin 3756135 plays a crucial role in maintaining the integrity of the engine’s internal mechanisms, ensuring smooth and efficient operation.

KTA Series Engines

- KTA19GC

- KTA19GC CM558

- KTA38GC CM558

The KTA series engines, including the KTA19GC, KTA19GC CM558, and KTA38GC CM558, are engineered for high-performance and durability. The roll pin 3756135 is essential for these engines, providing the necessary support and alignment for various components.

N14 Series Engines

- N14 CELECT

- N14 CELECT PLUS

- N14 G

- N14 MECHANICAL

The N14 series engines, such as the N14 CELECT, N14 CELECT PLUS, N14 G, and N14 MECHANICAL, are versatile and widely used in various applications. The roll pin 3756135 is a key component in these engines, ensuring that all parts function correctly and efficiently.

NH/NT Series Engines

- NH/NT 855

The NH/NT 855 engine is designed for heavy-duty applications and requires precise alignment of its components. The roll pin 3756135 is essential for maintaining the structural integrity of this engine.

QSK Series Engines

- QSK19G

- QSK38 CM850 MCRS

- QSK60 CM500

- QSK60G

- QSK78 CM500

The QSK series engines, including the QSK19G, QSK38 CM850 MCRS, QSK60 CM500, QSK60G, and QSK78 CM500, are known for their reliability and performance. The roll pin 3756135 is a vital part of these engines, ensuring that all moving parts remain properly aligned.

QSM and QSN Series Engines

- QSM11 CM570

- QSN14 CM876 N103

The QSM11 CM570 and QSN14 CM876 N103 engines are designed for specific applications requiring high performance and durability. The roll pin 3756135 is essential for these engines, providing the necessary support and alignment.

QST Series Engine

- QST30 CM552

The QST30 CM552 engine is engineered for specific applications, and the roll pin 3756135 is a crucial component, ensuring that all parts function correctly and efficiently.

V Series Engine

- V28

The V28 engine is designed for heavy-duty applications, and the roll pin 3756135 is essential for maintaining the structural integrity of this engine.

X Series Engine

- X15 CM2350 X123B

The X15 CM2350 X123B engine is engineered for high-performance applications. The roll pin 3756135 is a key component, ensuring that all parts function correctly and efficiently.

This roll pin is a testament to Cummins’ commitment to quality and reliability, ensuring that all compatible engines operate smoothly and efficiently.

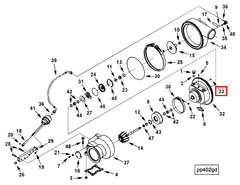

Role of Part 3756135 Roll Pin in Engine Systems

The part 3756135 Roll Pin is an integral component in various engine systems, facilitating smooth operation and efficient performance. Its application spans across multiple assemblies and subsystems, ensuring the precise functioning of mechanical parts.

Integration with Turbocharger Systems

In turbocharger setups, particularly within the Heat3B and Heat60 Turbocharger configurations, the Roll Pin is employed to secure the turbine housing to the compressor housing. This alignment is vital for maintaining the structural integrity and operational efficiency of the turbocharger. Additionally, in the Turbine Housing Repair Kit, the Roll Pin ensures that repaired components are correctly aligned, restoring the turbocharger’s performance to optimal levels.

Application in Core Assemblies

The Roll Pin is utilized in several core assemblies, including the Core Assembly Heat3B, Core Assembly Heat60, and Core Assembly HT3B (DCM). In these assemblies, it plays a key role in securing the connecting rod to the piston, ensuring smooth reciprocation and reducing wear on the components. This is particularly important in high-performance engines where precision and durability are paramount.

Role in Camshaft and Valve Train Systems

Within the Camshaft Mounting system, the Roll Pin is used to secure the camshaft in place, allowing for accurate valve timing and operation. This is essential for the engine’s overall performance, as any misalignment can lead to decreased efficiency and potential damage to the valve train components.

Use in Aftermarket and Performance Parts

For aftermarket turbochargers and performance parts, the Roll Pin is often a component of choice due to its reliability and precision. In systems like the Aftermarket Turbocharger and EBM: Performance Parts, it ensures that high-stress components are securely fastened, contributing to the enhanced performance and durability of the engine.

Application in Heat Exchanger Assemblies

In the Core Heat Exchanger60W Assembly, the Roll Pin is used to maintain the alignment of the heat exchanger components. This is crucial for the efficient transfer of heat, which is a key factor in the performance of the engine’s cooling system.

Integration with Liner Packs and Injector Systems

The Roll Pin is also found in Liner Packs, where it helps in securing the cylinder liners, ensuring they are correctly positioned for optimal engine operation. In Injector Systems, it is used to maintain the precise alignment of injector components, which is essential for fuel delivery accuracy and engine performance.

Use in Supercore and Assembly Core Systems

In the 4LGK Supercore and Assembly Core systems, the Roll Pin is employed to secure various components, ensuring the structural integrity and operational efficiency of these critical engine parts.

Conclusion

In summary, the Cummins 3756135 Roll Pin is a versatile component that plays a significant role in the precise alignment and secure fastening of various engine components across different systems. Its application is widespread, contributing to the overall performance, durability, and efficiency of the engine.

-

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ -

Lakshminarayanan, P. A., & Agarwal, Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer, 2019.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.