This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3931494 Pivot Pin is a component designed for use in commercial trucks. It serves a specific function within the truck’s mechanical system, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance 1.

Purpose and Function

The pivot pin plays a role in the truck’s mechanical system by facilitating the movement and stability of certain components. It operates as a pivot point, allowing parts to rotate or swing as needed during the truck’s operation. This movement is essential for various functions, including the operation of suspension systems, steering mechanisms, and other moving parts that require a stable yet flexible connection 2.

Key Features

The Cummins 3931494 Pivot Pin is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The design specifications of the pivot pin include precise dimensions and a robust structure, which contribute to its reliability under the demanding conditions of commercial truck use. Additionally, any unique attributes, such as special coatings or treatments, further improve its performance and longevity 3.

Benefits

Using the Cummins 3931494 Pivot Pin offers several advantages. It contributes to improved truck performance by ensuring smooth and reliable operation of the components it connects. Enhanced safety is another benefit, as the pivot pin’s durability and stability help prevent mechanical failures that could lead to accidents. Furthermore, the longevity of the component reduces the need for frequent replacements, offering cost savings and reduced maintenance efforts over time.

Installation and Usage

Proper installation of the Cummins 3931494 Pivot Pin is crucial for its optimal performance. The installation process involves securing the pivot pin in its designated location within the truck’s system, ensuring it is properly aligned and tightened according to manufacturer specifications. Correct usage practices, such as regular inspections and maintenance, are also important to ensure the pivot pin continues to function effectively throughout its service life.

Troubleshooting and Maintenance

Common issues with the pivot pin may include wear, corrosion, or misalignment. Troubleshooting steps involve inspecting the pin for signs of damage or excessive wear, ensuring it is properly lubricated, and checking its alignment within the system. Maintenance tips to prolong the life of the pivot pin include regular cleaning, lubrication, and monitoring for any signs of wear or damage that may require attention.

Compatibility and Applications

The Cummins 3931494 Pivot Pin is designed for use in specific types of trucks and systems. It fits into various truck models and is applicable in different operational scenarios, contributing to the efficient and reliable operation of the vehicle. Understanding its compatibility and applications is important for ensuring it is used in the correct context and for the intended purpose.

Manufacturer Information - Cummins

Cummins is a well-established manufacturer in the automotive and heavy-duty truck parts industry. With a history of innovation and a commitment to quality, Cummins has built a reputation for producing reliable and high-performance components. Their focus on research and development ensures that their products, including the Cummins 3931494 Pivot Pin, meet the demanding requirements of commercial truck applications.

Pivot Pin 3931494 in Cummins Engines

The Pivot Pin 3931494, manufactured by Cummins, is a critical component in several engine models. This part is integral to the engine’s operation, ensuring smooth movement and proper alignment of various parts.

Application in Specific Engines

- 6B5.9 Engine Series

- The Pivot Pin 3931494 is used in the 6B5.9 engine series. This engine is known for its robust design and reliability, often utilized in heavy-duty applications. The pivot pin plays a vital role in maintaining the alignment of the engine’s moving parts, contributing to the engine’s overall efficiency and longevity.

Importance in Engine Functionality

-

Alignment and Stability

- The pivot pin ensures that the connected parts move in a synchronized manner, reducing wear and tear. This alignment is crucial for the engine’s performance and durability.

-

Smooth Operation

- By facilitating smooth movement, the pivot pin helps in minimizing friction and noise, leading to a more efficient engine operation.

Compatibility and Usage

-

Interchangeability

- The Pivot Pin 3931494 is designed to be compatible with various parts within the engine, ensuring that it fits seamlessly into the engine’s architecture.

-

Maintenance and Replacement

- Regular inspection and timely replacement of the pivot pin are essential to maintain the engine’s performance. Any signs of wear or damage should be addressed promptly to prevent potential engine issues.

Role of Part 3931494 Pivot Pin in Engine Systems

The Part 3931494 Pivot Pin is an integral component in the operation of several engine systems, facilitating smooth and precise movements essential for optimal engine performance.

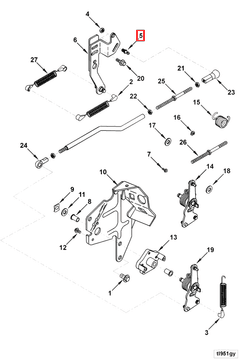

In the Bell Crank Lever system, the Pivot Pin allows for the necessary rotational movement that translates the linear motion of the throttle control into angular motion. This conversion is vital for adjusting the engine’s throttle setting accurately.

Within the Throttle Control Bracket, the Pivot Pin ensures that the bracket can pivot smoothly. This smooth pivoting action is essential for maintaining consistent throttle positions, which directly influences the engine’s RPM and overall performance.

In a Throttle Kit, the Pivot Pin plays a role in connecting various components, allowing them to move in unison. This synchronized movement is necessary for the precise control of fuel and air mixture, which is fundamental for efficient combustion.

Lastly, in the Throttle Lever assembly, the Pivot Pin enables the lever to move freely and without friction. This free movement ensures that the driver or operator can make fine adjustments to the throttle, providing better control over the engine’s power output.

Conclusion

The Cummins 3931494 Pivot Pin is a vital component in the operation of commercial trucks and Cummins engines, ensuring smooth movement and proper alignment of various parts. Its high-quality construction, precise design, and compatibility with specific engine models make it an essential part for maintaining engine efficiency and longevity. Regular maintenance and timely replacement are key to ensuring the pivot pin continues to perform its critical function effectively.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.