4001416

Piston Pin

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

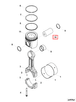

The Piston Pin Connector 4001416, manufactured by Cummins, is a critical component in the operation of heavy-duty truck engines. This part facilitates the connection between the piston and the connecting rod, ensuring efficient power transmission within the engine. Cummins is renowned for its commitment to quality and innovation in engine components. Understanding the function and importance of the Piston Pin Connector is essential for maintaining and optimizing the performance of heavy-duty truck engines.

Basic Concepts of Piston Pin Connectors

A Piston Pin Connector is a mechanical component that links the piston to the connecting rod in an internal combustion engine. Its primary function is to allow the piston to move up and down within the cylinder while the connecting rod converts this linear motion into rotational motion at the crankshaft. The connector must withstand significant forces and operate under high temperatures, necessitating robust design and material selection. The mechanical principles behind its operation involve the transfer of force and motion, ensuring smooth and efficient engine operation 1.

Purpose of the 4001416 Piston Pin Connector

The 4001416 Piston Pin Connector is specifically designed to enhance the connection between the piston and the connecting rod in truck engines. By providing a secure and durable link, it enables the efficient transfer of power from the piston’s reciprocating motion to the rotational motion of the crankshaft. This part is engineered to handle the stresses and loads encountered in heavy-duty applications, contributing to the engine’s overall performance and reliability 2.

Key Features

The 4001416 Piston Pin Connector features a design that prioritizes durability and performance. It is constructed from high-quality materials that offer resistance to wear and corrosion. The connector’s design includes precision-machined surfaces to ensure a tight fit and smooth operation. Additionally, it may incorporate features such as reinforced bearing surfaces or specialized coatings to enhance its longevity and functionality in demanding environments 3.

Benefits

Utilizing the 4001416 Piston Pin Connector offers several advantages. It contributes to improved engine efficiency by ensuring a reliable connection between the piston and connecting rod. This results in reduced wear and tear on engine components, leading to enhanced reliability and longevity. The connector’s design and materials also help in minimizing friction and heat generation, further contributing to the engine’s performance and efficiency.

Installation Process

Installing the 4001416 Piston Pin Connector requires careful attention to detail to ensure proper fit and function. The process involves aligning the connector with the piston and connecting rod, ensuring that all surfaces are clean and free from debris. Specific tools may be required to secure the connector in place, and it is important to follow manufacturer guidelines to avoid damage during installation. Best practices include verifying the alignment and fit before final assembly to ensure optimal performance.

Troubleshooting and Maintenance

Common issues with Piston Pin Connectors can include wear, misalignment, or damage due to excessive stress or improper installation. Regular maintenance practices, such as inspecting for signs of wear or damage and ensuring proper lubrication, can help prevent these issues. If wear or damage is detected, it may be necessary to replace the connector to maintain engine performance. Monitoring the condition of the connector and addressing issues promptly can extend its lifespan and ensure reliable engine operation.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer with a long history of producing high-quality engine components. The company is recognized for its commitment to innovation, quality, and customer satisfaction. Cummins offers a wide range of engine parts and technologies designed to meet the demands of various applications, including heavy-duty trucks. Their reputation in the industry is built on a foundation of reliable products and a dedication to advancing engine technology.

Piston Pin Connector 4001416 Compatibility with Cummins Engines

The Piston Pin Connector part number 4001416, manufactured by Cummins, is designed to fit seamlessly within a variety of their engine models. This part is integral to the engine’s operation, ensuring the piston pin is securely connected to the piston.

QSK45 CM500 and QSK60 CM500

Both the QSK45 CM500 and QSK60 CM500 engines are equipped with this Piston Pin Connector. These engines are known for their robust design and reliability, making them suitable for heavy-duty applications. The part 4001416 is engineered to meet the specific requirements of these engines, ensuring optimal performance and longevity.

QSK60 CM850 MCRS and QSK60 G CM2358 K110

The QSK60 CM850 MCRS and QSK60 G CM2358 K110 engines also utilize the Piston Pin Connector 4001416. These engines are part of Cummins’ lineup of high-performance, marine-grade engines, designed to deliver exceptional power and efficiency. The connector’s design ensures it fits perfectly within the architecture of these engines, providing the necessary support and stability.

QSK60G

The QSK60G engine is another model that incorporates the Piston Pin Connector 4001416. This engine is known for its versatility and is often used in various industrial applications. The connector’s compatibility with the QSK60G ensures that the engine operates smoothly, with minimal wear and tear on the piston pin assembly.

Role of Part 4001416 Piston Pin Connector in Engine Systems

The part 4001416 Piston Pin Connector is integral to the efficient operation of several key components within an engine system. Its primary function is to securely connect the piston to the connecting rod, allowing for smooth and precise movement as the engine operates.

Interaction with Connecting Rod and Piston

The Piston Pin Connector ensures that the connecting rod is firmly attached to the piston. This connection is vital for the transfer of force from the piston’s reciprocating motion to the rotational motion of the crankshaft. The secure fit provided by the connector allows for consistent and reliable power transmission, which is essential for the engine’s performance and durability.

Contribution to Engine Piston and Engine Piston Kit

Within an engine piston kit, the Piston Pin Connector plays a significant role in maintaining the structural integrity of the piston. It helps in evenly distributing the loads experienced during combustion, thereby reducing wear and tear on the piston and connecting rod. This results in enhanced performance and longevity of the engine piston components.

Impact on Engine Top Level Assembly Piston

In the engine top-level assembly, the Piston Pin Connector contributes to the overall stability and balance of the piston. Proper connection ensures that the piston moves smoothly within the cylinder, minimizing friction and potential damage to the cylinder walls. This is particularly important in high-performance engines where precision and reliability are paramount.

Relationship with Cylinder Head and Injector

The efficient operation of the Piston Pin Connector also indirectly affects components like the cylinder head and injector. A well-connected piston ensures that the combustion process is consistent, which in turn allows the injector to deliver fuel more accurately. This precision combustion leads to better engine performance and fuel efficiency.

Design and Performance Parts

In the context of engine design and performance parts, the Piston Pin Connector is often considered in the development of high-performance engines. Engineers may opt for alternative designs or materials to enhance the connector’s durability and performance under extreme conditions. This attention to detail in the connector’s design can lead to significant improvements in engine power output and reliability.

Wiring Retainer Bracket

Although not directly related, the Piston Pin Connector’s reliable performance can influence the design of ancillary components like the wiring retainer bracket. A stable and well-functioning piston assembly reduces the likelihood of unexpected movements or vibrations, which can affect the placement and security of wiring and other electrical components within the engine bay.

Conclusion

The 4001416 Piston Pin Connector is a fundamental component that ensures the smooth and efficient operation of various engine parts, contributing to the overall performance and reliability of the engine system. Its role in connecting the piston to the connecting rod is crucial for the efficient transfer of power within the engine, making it an essential part of heavy-duty truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.