This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4095782 Guide Pin is a component designed for use in commercial trucks. It serves a specific function within the truck’s mechanical systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is important for maintaining and optimizing the performance of heavy-duty trucks.

Basic Concepts of Guide Pins

Guide pins are mechanical components used in various types of machinery to ensure precise alignment and smooth operation of moving parts. In the context of heavy-duty trucks, guide pins play a role in maintaining the correct positioning of components within the engine or other systems, which is vital for the truck’s operation. They help in reducing wear and tear by ensuring that parts move within their intended paths 1.

Purpose of the Cummins 4095782 Guide Pin

This Cummins part is integral to the operation of a truck, particularly within the engine system. It functions by guiding specific components, ensuring they operate within the designed parameters. This guidance helps in maintaining the integrity of the engine’s moving parts, contributing to the truck’s overall performance and longevity 2.

Key Features

The Cummins 4095782 Guide Pin is characterized by its robust material composition, which is designed to withstand the high stresses and temperatures encountered in heavy-duty truck engines. Its design includes precise dimensions and surface treatments that enhance its durability and performance. These features ensure that the guide pin can effectively perform its role under demanding conditions 3.

Benefits

The use of this part offers several advantages. It contributes to improved engine efficiency by ensuring components operate smoothly and within their intended paths. Its durable construction enhances the longevity of the truck’s engine, reducing the need for frequent replacements. Additionally, the guide pin’s design helps in minimizing maintenance requirements, contributing to the truck’s overall performance.

Installation and Usage

Proper installation of the Cummins 4095782 Guide Pin is important for its effective function. The process involves ensuring the engine is correctly prepared, using the appropriate tools for installation, and following manufacturer guidelines to secure the guide pin in place. Careful attention to these steps ensures the guide pin can perform its role effectively.

Troubleshooting and Maintenance

Common issues with guide pins may include wear or misalignment, which can affect the truck’s performance. Diagnosing these problems involves inspecting the guide pin for signs of damage or improper alignment. Regular maintenance, including cleaning and checking for wear, can help in ensuring the guide pin continues to function effectively, contributing to the truck’s reliability.

Safety Considerations

When working with guide pins, it is important to follow safety practices to protect both the technician and the equipment. This includes using the correct tools for installation and maintenance, ensuring the engine is properly secured before beginning work, and following all manufacturer safety guidelines. These practices help in preventing accidents and ensuring the guide pin is installed and maintained correctly.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products that include engines, filtration systems, and powertrain components. With a history of innovation and quality, Cummins has established a strong reputation for producing reliable and high-performance parts for the trucking industry. The company’s commitment to excellence is reflected in its products, including the Cummins 4095782 Guide Pin.

Guide Pin 4095782 Compatibility with Cummins Engines

The Guide Pin 4095782, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is integral for ensuring the proper alignment and operation of engine components.

QSK23 Series

- QSK23 CM2250 K109

- QSK23 CM2350 K127

The Guide Pin 4095782 is compatible with both the QSK23 CM2250 K109 and QSK23 CM2350 K127 engines. These engines are part of the QSK23 series, which is known for its robust design and high performance. The guide pin ensures that the engine’s internal components remain aligned, contributing to the overall efficiency and longevity of the engine.

QSK23 CM500

The Guide Pin 4095782 is also suitable for the QSK23 CM500 engine. This model is part of the same series and shares many design elements with the other QSK23 engines. The guide pin’s role in this engine is to maintain the precise alignment of moving parts, which is crucial for the engine’s smooth operation and durability.

Summary

The Guide Pin 4095782 is a critical component for the QSK23 series engines, including the QSK23 CM2250 K109, QSK23 CM2350 K127, and QSK23 CM500. Its design ensures that these engines operate efficiently and reliably by maintaining the alignment of essential parts.

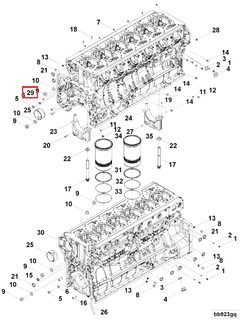

Role of Part 4095782 Guide Pin in Engine Systems

This part is integral to the efficient operation of several key components within engine systems. Its primary function is to ensure precise alignment and smooth movement of various parts, thereby enhancing the overall performance and longevity of the engine.

Block and Cylinder Assembly

In the block and cylinder assembly, the Guide Pin facilitates the accurate positioning of the cylinder within the engine block. This alignment is essential for maintaining the structural integrity of the assembly and ensuring that the cylinder operates within specified tolerances. Proper alignment reduces wear and tear on the cylinder walls and enhances the sealing efficiency between the piston and cylinder, leading to improved combustion efficiency.

Cam Follower Assembly

Within the cam follower assembly, the Guide Pin plays a role in maintaining the correct orientation of the cam followers relative to the camshaft. This ensures that the valve timing is consistent, which is vital for the engine’s performance. Accurate valve operation prevents issues such as valve float or interference, which can lead to significant engine damage.

Cylinder Block

In the cylinder block, the Guide Pin assists in the alignment of various components, such as the crankshaft and connecting rods. This precise alignment is necessary for the smooth operation of the pistons within the cylinders. It helps in reducing friction and wear on the piston skirts and cylinder walls, thereby contributing to the engine’s durability and efficiency.

Lubricating Oil Pump

The Guide Pin is also utilized in the lubricating oil pump to ensure that the pump components are correctly aligned. This alignment is crucial for the efficient distribution of lubricating oil throughout the engine. Proper lubrication reduces friction between moving parts, minimizes wear, and helps in dissipating heat, all of which are essential for the engine’s reliable operation.

Pump and Lubricating Oil System

In the broader lubricating oil system, the Guide Pin ensures that all components, including filters and passages, are correctly aligned. This alignment is vital for maintaining the flow of lubricating oil to all critical engine parts. Consistent oil flow prevents hotspots and reduces the risk of component failure due to inadequate lubrication.

Conclusion

Overall, the Part 4095782 Guide Pin is a fundamental component in ensuring the precise alignment and smooth operation of various engine systems, contributing to the engine’s efficiency, reliability, and longevity.

-

Hilgers, Michael. The Drivers Cab. Springer Vieweg, 2022.

↩ -

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Bonneau, Dominique, Aurelian Fatu, and Dominique Souchet. Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.