This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4385554 Pivot Pin is a component designed for use in commercial trucks. It serves a specific function within the truck’s mechanical system, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and significance is key to maintaining the truck’s performance and reliability.

Basic Concepts of Pivot Pins

Pivot pins are mechanical components used to allow rotation or pivoting motion between two parts. In heavy-duty trucks, pivot pins play a role in various systems, enabling smooth operation and efficient load distribution. They are integral to the functionality of components such as suspension systems, steering mechanisms, and other moving parts where rotational movement is required 1.

Purpose of the Cummins 4385554 Pivot Pin

The Cummins 4385554 Pivot Pin is designed to facilitate the pivoting motion in specific applications within a truck’s mechanical system. Its role is to provide a durable and reliable pivot point, ensuring that connected components can move as intended without excessive wear or failure. This contributes to the truck’s overall operational efficiency and longevity.

Key Features

This Cummins part is constructed from high-quality materials, ensuring durability and resistance to wear. Its design includes precise dimensions and tolerances to fit securely within the truck’s mechanical system. Unique characteristics such as surface treatments may be applied to enhance performance, reduce friction, and improve longevity.

Benefits of Using the Cummins 4385554 Pivot Pin

Utilizing this part offers several advantages. Its robust construction contributes to the durability and reliability of the truck’s mechanical system. The pin’s design and material composition enhance efficiency, reducing the likelihood of premature wear or failure. This results in improved truck performance and reduced maintenance requirements.

Installation Process

Installing the Cummins 4385554 Pivot Pin requires following a specific procedure to ensure proper fit and function. The process involves preparing the installation site, aligning the pin with the corresponding components, and securing it in place. Tools and equipment necessary for installation may include wrenches, alignment tools, and possibly a press or hammer for seating the pin. Safety precautions, such as wearing personal protective equipment (PPE) and ensuring the truck is securely supported, are crucial during installation 2.

Maintenance and Care

Regular maintenance and care of the Cummins 4385554 Pivot Pin are important for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, cleaning to remove dirt and debris, and lubrication to reduce friction and wear. Following manufacturer guidelines for maintenance intervals and procedures will help maintain the pin’s condition and functionality.

Troubleshooting Common Issues

Common issues associated with pivot pins may include wear, misalignment, or damage due to excessive load or improper installation. Identifying these problems early can prevent more significant issues. Troubleshooting steps may involve inspecting the pin and surrounding components for wear or damage, ensuring proper alignment, and replacing the pin if necessary. Consulting service manuals or seeking professional assistance can provide guidance on resolving these issues 3.

Safety Considerations

When working with pivot pins, including the Cummins 4385554, safety practices are paramount. This involves using personal protective equipment (PPE) such as gloves and safety glasses to protect against injury. Operational safety measures include ensuring the truck is securely supported during maintenance or installation work and following all manufacturer guidelines and safety instructions.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on technological advancement make it a preferred choice for commercial vehicle operators and manufacturers.

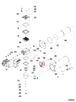

Pivot Pin 4385554 Compatibility with Cummins Engines

The Pivot Pin part number 4385554, manufactured by Cummins, is a critical component in several of their engine models. This part is integral to the smooth operation of the engine’s internal mechanisms, ensuring that various parts move as intended without undue friction or wear.

QSK95 Series

The QSK95 series engines benefit from the Pivot Pin 4385554 in maintaining the alignment and functionality of the engine’s moving parts. This series is known for its robust design and high performance, making it suitable for heavy-duty applications. The pivot pin’s precision engineering ensures that the engine’s components operate smoothly, contributing to the overall reliability and longevity of the engine.

CM2350 Series

In the CM2350 series, the Pivot Pin 4385554 plays a crucial role in the engine’s operation. This series is designed for medium-duty applications, providing a balance between power and efficiency. The pivot pin’s design allows for precise movement and alignment, which is essential for the engine’s performance and durability.

K113 Series

The K113 series engines also utilize the Pivot Pin 4385554. This series is typically used in applications where reliability and efficiency are paramount. The pivot pin ensures that the engine’s components move with the exact precision required, enhancing the engine’s performance and reducing the likelihood of mechanical failures.

By integrating the Pivot Pin 4385554 into these engines, Cummins ensures that each model maintains its operational integrity and efficiency. This part’s compatibility across multiple engine series underscores its importance in the overall design and functionality of Cummins engines.

Role of Part 4385554 Pivot Pin in Engine Systems

The 4385554 Pivot Pin is a fundamental component in various engine systems, facilitating smooth operation and efficient performance. Its role can be observed in the following components:

Accessories

In the realm of engine accessories, the 4385554 Pivot Pin ensures the precise movement of components such as alternators, power steering pumps, and air conditioning compressors. By providing a stable pivot point, it allows these accessories to rotate smoothly, reducing wear and tear and enhancing the longevity of the system.

Fuel System

Within the fuel system, the Pivot Pin is integral to the operation of fuel injectors and carburetor components. It enables the accurate and consistent movement required for fuel delivery, ensuring that the engine receives the correct fuel-air mixture for optimal combustion. This results in improved fuel efficiency and reduced emissions.

Fuel Filter

The Pivot Pin also plays a part in the fuel filter assembly. It assists in the smooth operation of the filter housing, allowing for easy maintenance and replacement. This ensures that the fuel system remains clean and free from contaminants, which is essential for the engine’s performance and durability.

Service Kit

In a service kit, the 4385554 Pivot Pin is often included to replace worn-out pivot points during routine maintenance. Its inclusion in the kit ensures that all moving parts within the engine system can be restored to their original specifications, maintaining the engine’s efficiency and reliability over time.

Conclusion

The Cummins 4385554 Pivot Pin is a critical component in the operation and maintenance of commercial trucks and Cummins engines. Its role in facilitating smooth pivoting motion, ensuring precise alignment, and contributing to the overall efficiency and reliability of the mechanical system cannot be overstated. Regular maintenance, proper installation, and adherence to safety practices are essential for maximizing the performance and longevity of this part.

-

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ -

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.