This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4391488 Roll Pin is a component manufactured by Cummins, a well-established name in the commercial truck industry. This part is significant in commercial truck applications due to its role in ensuring the secure operation of various truck systems. Understanding its function and importance can provide valuable insights into maintaining and optimizing truck performance.

Basic Concepts of Roll Pins

Roll pins are cylindrical fasteners used in mechanical systems to secure components in place. They function by being pressed into pre-drilled holes that span across two or more parts, holding them together without the need for additional fasteners. This method ensures that the components remain aligned and stationary relative to each other, which is crucial for the proper functioning of mechanical assemblies 1.

Purpose of the 4391488 Roll Pin in Truck Operations

The 4391488 Roll Pin plays a specific role in the operation of commercial trucks by securing components within various truck systems. It is commonly used in applications where precise alignment and secure fastening are required, such as in the engine, transmission, and other critical systems. By holding parts in place, it contributes to the smooth and efficient operation of these systems 2.

Key Features of the 4391488 Roll Pin

The 4391488 Roll Pin is designed with specific characteristics that enhance its effectiveness and durability in heavy-duty applications. It is typically made from high-strength materials to withstand the rigors of commercial truck use. Its design ensures a tight fit within the drilled holes, providing a secure connection that resists movement and wear over time 3.

Benefits of Using the 4391488 Roll Pin

Using the 4391488 Roll Pin offers several advantages. It provides improved reliability by ensuring that components remain securely in place, reducing the risk of misalignment or failure. Additionally, its design allows for ease of installation, as it can be pressed into place without the need for complex tools or procedures. Maintenance benefits include the ability to replace the roll pin if necessary, without requiring extensive disassembly of the truck’s systems.

Installation and Usage Guidelines

Proper installation of the 4391488 Roll Pin involves several steps to ensure a secure fit. First, the holes in the components to be joined must be clean and free of debris. Using a press or similar tool, the roll pin is then inserted into the holes until it is flush with the surfaces. Care should be taken to ensure that the pin is straight and fully seated to avoid any potential issues with component alignment or stability.

Troubleshooting Common Issues

Typical problems with roll pins may include misalignment, wear, or damage. If a roll pin is suspected to be the cause of an issue, it should be inspected for signs of wear or damage. Misalignment can often be corrected by ensuring that the components are properly positioned before inserting the roll pin. In cases of wear or damage, replacement of the roll pin may be necessary to restore proper function.

Maintenance Tips

Regular inspection and maintenance of the 4391488 Roll Pin can help prolong its service life and ensure optimal performance. This includes checking for signs of wear or damage during routine maintenance checks and replacing the roll pin if necessary. Keeping the areas around the roll pin clean and free of debris can also help prevent issues related to contamination or corrosion.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance products. Their extensive product range and commitment to innovation have made them a preferred choice for commercial truck applications worldwide.

Cummins Engine Part 4391488 Roll Pin Compatibility

The Cummins part 4391488, a Roll Pin, is a critical component in the assembly and operation of various Cummins engines. This roll pin is designed to provide secure and reliable connections between different parts of the engine, ensuring smooth and efficient operation.

QSK95 and CM2350 Engines

The QSK95 and CM2350 engines, both part of Cummins’ high-performance lineup, utilize the 4391488 Roll Pin in several key areas. In these engines, the roll pin is often employed to secure components such as the valve train, connecting rods, and other critical assemblies. Its robust design ensures that these parts remain tightly fastened under the extreme conditions these engines operate in, contributing to the overall durability and reliability of the engines.

K113 Engine

The K113 engine, known for its versatility and efficiency, also incorporates the 4391488 Roll Pin in its design. In this engine, the roll pin is used to maintain the alignment and stability of various moving parts, ensuring that the engine runs smoothly and efficiently. The precision engineering of the roll pin is crucial in maintaining the integrity of the engine’s internal components, which is essential for the K113’s performance in demanding applications.

Grouping of Engines

The QSK95 and CM2350 engines, while distinct in their specific applications, share a commonality in their use of the 4391488 Roll Pin. Both engines are designed for heavy-duty applications, and the roll pin’s role in these engines is to provide a reliable connection that can withstand high stress and frequent use. The K113 engine, while different in its design and intended use, also benefits from the roll pin’s ability to secure and align critical components, ensuring the engine’s longevity and performance.

Role of Part 4391488 Roll Pin in Engine Systems

The 4391488 Roll Pin is an essential component in various engine systems, ensuring the smooth operation and synchronization of multiple parts.

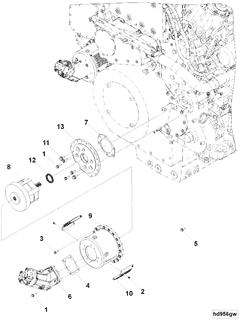

In the Coupling Drive system, the Roll Pin facilitates the secure connection between the drive shaft and the coupling mechanism. This allows for efficient power transmission from the engine to the driven components, ensuring that rotational force is consistently and reliably delivered.

Within the Pump system, the Roll Pin plays a significant role in maintaining the alignment and stability of the pump’s rotating elements. It ensures that the pump components operate in unison, which is vital for the consistent flow of fluids through the engine system. This alignment is necessary for the pump to function effectively, providing the necessary lubrication and cooling to various engine parts.

In the Auxiliary systems, such as those involving secondary drives or accessory components, the Roll Pin helps in maintaining the precise positioning of gears and shafts. This is important for the operation of components like alternators, power steering pumps, and air conditioning compressors, ensuring that these systems receive the correct amount of power and operate smoothly.

Overall, the 4391488 Roll Pin is a key element in ensuring the reliable and efficient operation of these engine systems, contributing to the overall performance and longevity of the engine.

Conclusion

The 4391488 Roll Pin by Cummins is a vital component in the operation and maintenance of commercial trucks and engines. Its role in securing components, ensuring alignment, and facilitating efficient power transmission underscores its importance in the automotive industry. Proper installation, regular maintenance, and timely replacement of this part can significantly enhance the performance and longevity of truck and engine systems.

-

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Reif, K. (2015). Automotive Mechatronics. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.