This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5335463 Straight Pin, manufactured by Cummins, is a component utilized in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts designed to enhance the performance and reliability of heavy-duty vehicles. This part is integral to the mechanical systems of these trucks, playing a role in the connection and alignment of various components.

Basic Concepts of Straight Pins

Straight pins are cylindrical fasteners used in mechanical and automotive applications to hold components together or align parts within an assembly. They function by providing a secure fit that prevents movement between parts, ensuring the stability and integrity of the assembly. In automotive applications, straight pins are often used in engine components, transmission systems, and other critical areas where precise alignment and secure fastening are required 1.

Purpose of the 5335463 Straight Pin in Truck Operations

The 5335463 Straight Pin serves a specific role in the operation of commercial trucks by connecting or aligning components within the vehicle’s mechanical systems. Its function is to maintain the proper positioning of parts, which is vital for the efficient operation of the truck. By ensuring that components are securely held in place, the straight pin contributes to the overall stability and performance of the truck 2.

Key Features

The 5335463 Straight Pin is characterized by several key features that enhance its performance and durability. These include its material composition, which is designed to withstand the rigors of commercial truck operations, and its precise dimensions, which ensure a secure fit within the assembly. Additionally, any unique design elements incorporated into the pin further contribute to its effectiveness in maintaining component alignment and stability 3.

Benefits of Using the 5335463 Straight Pin

Utilizing the 5335463 Straight Pin offers several advantages. These include improved mechanical stability within the truck’s systems, ease of installation due to its design, and long-term reliability. The pin’s ability to securely hold components in place contributes to the efficient operation of the truck, while its durability ensures that it can withstand the demands of commercial use over an extended period 4.

Installation and Usage Guidelines

Proper installation of the 5335463 Straight Pin involves following specific guidelines to ensure it functions correctly within the assembly. Best practices for usage include verifying the pin’s compatibility with other components and ensuring it is installed in the correct orientation. Adhering to these guidelines helps maintain the integrity of the assembly and ensures the pin performs its intended function effectively.

Troubleshooting and Maintenance

Common issues associated with straight pins can include misalignment or wear over time. Troubleshooting these problems may involve checking the pin’s fit within the assembly and inspecting it for signs of damage or corrosion. Maintenance tips to ensure the longevity and optimal performance of the 5335463 Straight Pin include regular inspection for wear and proper lubrication, if applicable, to prevent corrosion and ensure smooth operation.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products that enhance the performance and reliability of heavy-duty vehicles. With a history of innovation and quality, Cummins has established a strong reputation for producing parts that meet the demanding requirements of commercial truck operations. The company’s commitment to excellence is reflected in its product range, which includes engines, powertrain components, and aftermarket parts designed to support the efficiency and durability of commercial trucks.

Cummins Engine Compatibility with Part 5335463

The Straight Pin part number 5335463, manufactured by Cummins, is a critical component that fits into various Cummins engine models. This part is essential for the proper functioning and assembly of the engine, ensuring that different parts are correctly aligned and secured.

QSB6.7 M CM2250 and QSC8.3 CM850 (CM2850)

The Straight Pin 5335463 is compatible with the QSB6.7 M CM2250 and QSC8.3 CM850 (CM2850) engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The pin’s role in these engines is to maintain the integrity of the engine’s internal mechanisms, ensuring smooth operation and longevity.

QSM11 CM570

Similarly, the QSM11 CM570 engine also utilizes the Straight Pin 5335463. This engine is designed for applications requiring high power and durability, such as industrial and marine uses. The pin’s precision fit is crucial for the engine’s performance, providing the necessary stability and alignment for various engine components.

Application Across Engine Models

The compatibility of the Straight Pin 5335463 across these engines highlights its versatility and importance in Cummins’ engine lineup. Whether in the QSB6.7 M CM2250, QSC8.3 CM850 (CM2850), or QSM11 CM570, this part ensures that the engine operates efficiently and reliably. Its design and material are tailored to withstand the demanding conditions these engines face, making it a reliable choice for maintenance and repairs.

Role of Part 5335463 Straight Pin in Engine Systems

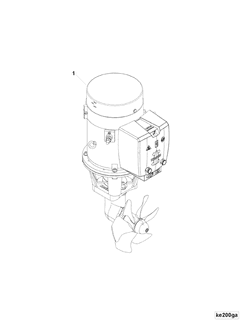

In the context of marine propulsion systems, the part 5335463 Straight Pin is instrumental in ensuring the smooth operation and structural integrity of various components.

Thruster Systems

Within thruster systems, the Straight Pin is utilized to secure and align components that are pivotal for the thruster’s functionality. It plays a significant role in maintaining the precise alignment of the thruster’s mechanical linkages, which are essential for the efficient transfer of power from the engine to the propeller. This alignment ensures that the thruster operates within its designed parameters, contributing to the vessel’s maneuverability and stability.

Bow Thruster

In bow thrusters, the Straight Pin is employed to connect and stabilize the various mechanical parts that facilitate the rotation of the propeller. Its role is to ensure that the components remain in the correct position under the stresses encountered during operation. This stability is vital for the consistent performance of the bow thruster, which is crucial for precise docking and maneuvering in tight spaces.

Stern Thruster

Similarly, in stern thrusters, the Straight Pin is used to secure the mechanical components that enable the stern thruster to function effectively. It ensures that the parts are held firmly in place, allowing for the smooth and reliable operation of the thruster. This is particularly important in larger vessels where the stern thruster plays a significant role in reversing and maneuvering.

Thruster Drive

The Straight Pin is also integral to the thruster drive mechanism. It helps in maintaining the alignment and integrity of the drive components, which are responsible for transmitting power from the engine to the thruster. This ensures that the thruster drive operates efficiently, contributing to the overall performance and reliability of the propulsion system.

Conclusion

In summary, the 5335463 Straight Pin is a key component in various engine systems, providing essential support and alignment to ensure the reliable and efficient operation of thrusters and their associated drives. Its role in maintaining the integrity and performance of commercial trucks and marine propulsion systems underscores its importance in the industry.

-

Thorsten Boger, Willard Cutler, Reducing Particulate Emissions in Gasoline Engines, SAE International, 2018.

↩ -

Frederick F. Ling, The Automotive Body, Springer Science, 2011.

↩ -

Michael Hilgers, Transmissions and Drivetrain Design, Springer Vieweg, 2022.

↩ -

Barry Kluczyk, How to Rebuild Any Automotive Engine, CarTech, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.