This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3021530 Clevis Pin is a specialized component designed for use in commercial truck operations. It serves as a pivotal element in connecting various parts of the truck’s mechanical system, ensuring smooth and efficient operation. Its role in maintaining the integrity and functionality of truck components underscores its significance in the realm of commercial trucking.

Basic Concepts of Clevis Pins

A clevis pin is a cylindrical fastener featuring a head at one or both ends. It is commonly used in mechanical systems to connect components that require pivoting or hinging motion. Within these systems, the clevis pin functions by securing the clevis, a U-shaped yoke, to another part, allowing for movement while maintaining a strong connection. This mechanism is vital for the operation of various machinery, including commercial trucks 1.

Purpose of the Cummins 3021530 Clevis Pin

This Cummins part is specifically engineered to play a role in the mechanical linkages of trucks. It is utilized in applications where components need to pivot or move relative to each other, such as in the steering or braking systems. Its purpose is to provide a secure, yet movable, connection between parts, ensuring the truck operates efficiently and safely.

Key Features

The 3021530 is distinguished by several key features. It is constructed from high-quality materials, ensuring durability and resistance to wear. The design includes a head on one end to prevent it from pulling through the clevis, and it may feature a cotter pin or similar device to secure it in place. These characteristics contribute to its reliability and effectiveness in demanding truck applications.

Benefits

The advantages of using this part include enhanced durability, reliability, and performance. Its robust construction allows it to withstand the rigors of commercial truck operation, while its design ensures a secure connection between moving parts. This results in improved efficiency and safety in truck mechanics.

Installation and Usage

Proper installation of the 3021530 involves aligning it with the clevis and inserting it until it is fully seated. It is then secured in place using a cotter pin or similar method to prevent it from coming loose. Best practices for usage include regular inspection for signs of wear or damage, and replacement as necessary to maintain optimal performance.

Troubleshooting and Maintenance

Common issues with the 3021530 may include wear, corrosion, or damage from improper installation. Maintenance tips to ensure longevity include regular inspection for signs of wear, cleaning to remove dirt and debris, and lubrication to reduce friction. Signs of wear or damage, such as rust or bending, may indicate the need for replacement.

Safety Considerations

When working with the 3021530, it is important to observe safety guidelines and precautions. This includes using the correct tools for installation and removal, ensuring the pin is properly secured, and conducting regular inspections to identify any issues that may compromise safety. Proper handling and maintenance procedures are crucial to prevent accidents or injuries.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes a variety of components designed to enhance the performance, efficiency, and reliability of commercial vehicles, reflecting the quality and reliability of the 3021530 2.

Clevis Pin 3021530 Compatibility with Cummins Engines

The Clevis Pin 3021530, manufactured by Cummins, is a critical component in the assembly of various engine systems. This part is designed to ensure secure and reliable connections between different engine parts, facilitating smooth operation and maintaining structural integrity.

K38 and K50 Engines

The Clevis Pin 3021530 is compatible with both the K38 and K50 engines. These engines, while distinct in their specific applications and configurations, share common design principles that necessitate the use of such a pin. In these engines, the Clevis Pin is typically employed in the linkage systems that connect the engine to various control mechanisms. Its role is pivotal in ensuring that the movement between connected parts is both precise and durable.

The K38 and K50 engines are part of a series that leverages the reliability and efficiency of Cummins technology. The Clevis Pin 3021530’s compatibility with these engines underscores its versatility and importance in maintaining the operational integrity of the engine’s mechanical systems.

Role of Part 3021530 Clevis Pin in Engine Systems

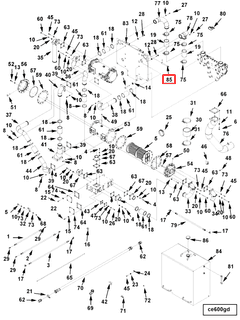

The 3021530 is an essential component in various engine systems, facilitating secure connections and efficient operation. In the context of an Exchanger, the Clevis Pin ensures the stability of linkages and pivot points, which are vital for the exchanger’s performance.

Within a Heat Exchanger system, the Clevis Pin plays a significant role by maintaining the integrity of connections between moving parts, allowing for smooth heat transfer processes. This is particularly important in systems where precise temperature regulation is required.

The Expansion Tank in an engine cooling system relies on the Clevis Pin to secure components that manage the expansion and contraction of coolant. This ensures that the tank can effectively handle pressure changes without compromising the system’s integrity.

In a Top Mounting Heat Exchanger Tank, the Clevis Pin is used to connect and stabilize the tank to the engine framework. This connection is essential for maintaining the structural integrity of the tank while it operates under varying thermal conditions.

Overall, the 3021530 contributes to the reliable functioning of engine systems by providing robust and secure connections between critical components.

Conclusion

The Cummins 3021530 Clevis Pin is a vital component in the operation and maintenance of commercial trucks and engines. Its design and features ensure durability, reliability, and efficient performance in demanding applications. Proper installation, maintenance, and adherence to safety guidelines are essential to maximize its benefits and ensure the safety and efficiency of truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.