This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

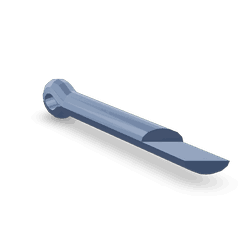

The Cotter Pin 4929940 by Cummins is a specialized fastener designed for use in commercial truck maintenance and operation. Its purpose is to secure various components within the truck’s mechanical assemblies, ensuring that parts remain in place under operational stress. The significance of this cotter pin lies in its ability to enhance the reliability and safety of truck systems by preventing unwanted movement or disconnection of critical components.

Basic Concepts of Cotter Pins

A cotter pin is a simple yet effective fastener used in mechanical assemblies to secure components that might otherwise loosen or separate. It typically consists of a metal pin with a bent end, which is inserted through a hole in the assembly and then bent or “clinched” to hold the parts together. This design ensures that the components remain fixed in place, reducing the risk of mechanical failure 3.

Purpose of Cotter Pin 4929940 in Truck Operation

The Cotter Pin 4929940 plays a specific role in the operation and maintenance of commercial trucks. It is commonly used in various truck systems, including the brake system, steering components, and engine assemblies. By securing these parts, the cotter pin helps maintain the integrity of the assembly, ensuring that the truck operates safely and efficiently. Its application is vital in environments where vibrations and dynamic loads are common, as it prevents components from loosening over time 2.

Key Features of Cotter Pin 4929940

The Cotter Pin 4929940 is designed with specific characteristics that enhance its functionality. It is typically made from high-strength steel, which provides durability and resistance to corrosion. The pin’s dimensions are precisely engineered to fit the intended applications, ensuring a secure fit. Additionally, the material composition and design features contribute to its ability to withstand various operating conditions, including high stress and temperature fluctuations 3.

Benefits of Using Cotter Pin 4929940

Using the Cotter Pin 4929940 offers several advantages. It provides improved security for mechanical assemblies, ensuring that components remain fixed in place. The design of the pin allows for easy installation and removal, making it convenient for maintenance tasks. Furthermore, its durability under various operating conditions ensures long-term reliability, reducing the need for frequent replacements 2.

Installation and Usage Guidelines

Proper installation of the Cotter Pin 4929940 is crucial for ensuring a secure fit and maintaining the integrity of the assembly. To install, insert the pin through the designated hole in the assembly. Once in place, bend the end of the pin to create a clinch, securing the components together. It is important to ensure that the pin is properly aligned and that the clinch is tight enough to prevent movement but not so tight that it damages the surrounding parts 3.

Troubleshooting Common Issues

Common issues associated with cotter pins include loosening or breakage. If a cotter pin becomes loose, it should be replaced immediately to prevent potential mechanical failure. Breakage can occur due to excessive stress or corrosion. Regular inspection and maintenance can help identify these issues early, allowing for timely replacement and continued safe operation of the truck 2.

Maintenance Tips

Regular inspection and maintenance of the Cotter Pin 4929940 are recommended to ensure ongoing reliability and performance. Inspect the pin for signs of wear or damage, such as bending or corrosion, which may indicate the need for replacement. Additionally, ensure that the clinch remains secure and that there is no excessive play in the assembly. Following these maintenance practices will help prolong the life of the cotter pin and ensure the continued safe operation of the truck 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, reliability, and efficiency of commercial vehicles 1.

Application in Cummins Engines

The Cotter Pin is utilized across a range of Cummins engines, including but not limited to the 6C8.3 series. Its primary function is to lock pins, bolts, and other fasteners in position, thereby maintaining the integrity of the engine’s mechanical components.

- 6C8.3 Engines: In the 6C8.3 engines, the Cotter Pin is often used to secure critical fasteners in the engine’s internal mechanisms. This ensures that parts such as valve train components, connecting rods, and other moving parts remain securely fastened, preventing any potential failure due to loosening 1.

Importance in Engine Maintenance

Regular inspection and replacement of the Cotter Pin are crucial for maintaining engine reliability. A compromised Cotter Pin can lead to the loosening of critical fasteners, which may result in severe engine damage or failure. Cummins engines, known for their durability and performance, rely on such precision components to function optimally 1.

Compatibility and Usage

The Cotter Pin part 4929940 is engineered to fit seamlessly into the design specifications of Cummins engines. Its compatibility extends across various models, ensuring that it can be used in multiple engine configurations within the Cummins lineup. This versatility makes it a standard part in the maintenance and repair kits for Cummins engines 1.

Role of Part 4929940 Cotter Pin in Engine Systems

In engine systems, the 4929940 Cotter Pin is instrumental in securing and maintaining the integrity of various components. Specifically, it plays a significant role in the assembly and operation of the control, manual throttle lever, and throttle control bracket.

Control System Integration

Within the control system, the 4929940 Cotter Pin is used to fasten components that require precise alignment and secure attachment. It ensures that moving parts within the control mechanism remain in their designated positions, thereby maintaining the efficiency and reliability of the control system. This is particularly important in systems where adjustments need to be made frequently, as the Cotter Pin allows for easy disassembly and reassembly without compromising the structural integrity of the control components 3.

Manual Throttle Lever Assembly

The manual throttle lever is a key component in many engine systems, allowing for direct control over the engine’s throttle. The 4929940 Cotter Pin is employed to secure the lever to its mounting bracket, ensuring that it operates smoothly and without unintended movement. This security is essential for maintaining consistent engine performance, especially in applications where manual adjustments are common. The Cotter Pin’s role here is to provide a reliable connection point that can withstand the forces exerted during operation 2.

Throttle Control Bracket Stability

The throttle control bracket serves as a pivotal point for the attachment of the throttle lever and other control components. The 4929940 Cotter Pin is utilized to secure the bracket to the engine or other structural elements, ensuring that it remains stable under varying operational conditions. This stability is vital for the accurate transmission of throttle commands from the lever to the engine, directly influencing the engine’s responsiveness and performance. The Cotter Pin’s presence in this assembly guarantees that the bracket does not shift or become misaligned, which could lead to inaccurate throttle settings and potentially dangerous operating conditions 3.

Conclusion

In summary, the 4929940 Cotter Pin is a fundamental component in the secure and efficient operation of control, manual throttle lever, and throttle control bracket assemblies within engine systems. Its application ensures that these components remain firmly in place, contributing to the overall reliability and performance of the engine.

-

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5659770, 2023.

↩ ↩ ↩ ↩ -

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ ↩ ↩ ↩ -

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩ ↩ ↩ ↩ ↩ ↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.