This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Cotter pins are small yet vital components used in mechanical systems to secure parts that are subject to vibration or rotation. They are commonly employed in various industries, including automotive and heavy-duty truck manufacturing. This article provides an overview of cotter pins and introduces the 4938406 Cotter Pin, a product manufactured by Cummins.

Basic Concepts of Cotter Pins

A cotter pin is a simple yet effective fastener designed to prevent components from loosening. It consists of a metal wire bent into a U-shape with one end split to allow it to be inserted into a hole and then bent back to secure the parts in place. Cotter pins are typically made from materials such as steel, stainless steel, or brass, chosen for their strength, corrosion resistance, and durability 1.

Purpose of the 4938406 Cotter Pin in Truck Operations

The 4938406 Cotter Pin by Cummins plays a specific role in the operation of commercial trucks. It is used to secure components that are prone to loosening due to vibration or rotational forces. By ensuring that these parts remain firmly in place, the cotter pin contributes to the overall functionality and safety of the vehicle. Its application is crucial in maintaining the integrity of truck assemblies under various operating conditions 2.

Key Features of the 4938406 Cotter Pin

The 4938406 Cotter Pin is designed with precision to meet the demanding requirements of truck operations. It features a robust construction with specific dimensions tailored for its intended use. Made from high-quality materials, it offers excellent strength and resistance to wear and corrosion. The unique characteristics of this cotter pin, such as its precise bend and split end, enhance its performance and reliability in securing truck components 3.

Benefits of Using the 4938406 Cotter Pin

Incorporating the 4938406 Cotter Pin into truck assemblies offers several advantages. Its durable construction ensures long-lasting performance, while its design allows for easy installation. The reliability of this cotter pin under various operating conditions makes it a preferred choice for securing critical components in commercial trucks.

Installation and Usage Guidelines

Proper installation of the 4938406 Cotter Pin is essential for its effective use. To install, insert the split end of the cotter pin into the designated hole and bend it back to secure the components. Ensure that the pin is properly seated and that the bent end is flush with the surface to prevent any protrusions that could cause damage or injury. Follow best practices to ensure a secure and effective installation.

Troubleshooting and Maintenance

Common issues with cotter pins include bending or breaking due to excessive force or corrosion. Regular inspection for signs of wear or damage is recommended to ensure the longevity and proper function of the 4938406 Cotter Pin. Maintenance tips include cleaning the pin and its surrounding area to prevent corrosion and replacing it if any signs of damage are detected.

Safety Considerations

When handling and installing cotter pins, it is important to follow safety practices to prevent injuries. Wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against sharp edges and flying debris. Ensure that the work area is clean and free from obstacles to maintain a safe working environment.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history in the commercial truck industry, Cummins is committed to quality and innovation in manufacturing truck components. The company’s dedication to excellence is evident in its products, including the 4938406 Cotter Pin, which is designed to meet the high standards required for commercial truck operations.

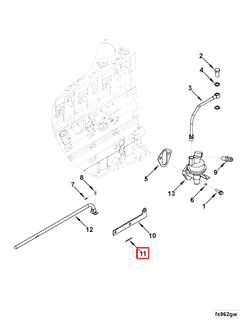

Cummins Engine Cotter Pin 4938406

The Cummins engine part 4938406, a Cotter Pin, is a critical component used across various Cummins engine models. This part is integral in securing and stabilizing certain engine parts, ensuring the longevity and reliability of the engine’s operation.

Application in Cummins Engines

- 4B3.9 and 6B5.9 Engines

The Cotter Pin 4938406 is specifically designed to fit within the operational framework of both the 4B3.9 and 6B5.9 engines. These engines, while differing in displacement and power output, share common design principles that necessitate the use of such a pin.

- Function and Importance

In these engines, the Cotter Pin is used to secure fasteners, such as bolts and screws, preventing them from loosening due to vibration or other operational stresses. This ensures that the engine components remain tightly fastened, maintaining the structural integrity and performance of the engine.

- Installation and Maintenance

Proper installation of the Cotter Pin 4938406 is crucial. It must be correctly inserted into the designated hole, ensuring it grips the fastener securely. Regular maintenance checks should be performed to verify that the pin remains in place and has not loosened over time, as a loose pin can lead to significant engine issues.

- Compatibility and Usage

The part number 4938406 is compatible with both the 4B3.9 and 6B5.9 engines, making it a versatile component for Cummins engine maintenance and repair. Its design ensures that it can be used across these models without modification, streamlining the maintenance process for technicians and engineers.

Cotter Pin Component Usage in Engine Systems

In the realm of engine systems, the part 4938406 Cotter Pin is instrumental in ensuring the secure assembly and operation of various components. Its role is particularly significant in the context of pumps and fuel transfer systems.

Role in Pumps

Within pump assemblies, the Cotter Pin serves as a pivotal fastening element. It is commonly used to secure the shaft within the pump housing, preventing any unwanted movement that could lead to misalignment or failure. This secure fit is essential for maintaining the pump’s efficiency and reliability, ensuring that the fluid dynamics within the pump are optimized for performance.

Role in Fuel Transfer Systems

In fuel transfer systems, the Cotter Pin is employed to lock components in place, such as securing the connection between the fuel lines and the pump or ensuring that the fuel filter housing remains intact. This is vital for maintaining the integrity of the fuel pathway, preventing leaks, and ensuring that the fuel is delivered consistently and efficiently to the engine. The secure fastening provided by the Cotter Pin helps in maintaining the pressure and flow rate necessary for optimal engine performance.

Conclusion

The 4938406 Cotter Pin by Cummins is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its robust design, ease of installation, and reliability under various operating conditions make it an essential part for securing components prone to loosening. Regular maintenance and proper installation are key to ensuring the longevity and performance of this part, contributing to the overall safety and efficiency of truck and engine operations.

-

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Hilgers, M. (2023). Entire Vehicle: Second Edition. Springer Nature.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.