This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

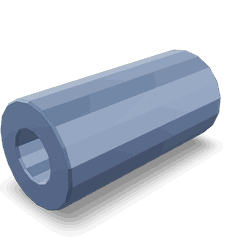

The Cummins 3064304 Piston Pin is a specialized component designed for use in heavy-duty truck engines. Its purpose is to facilitate the connection between the piston and the connecting rod, enabling the necessary movement and load distribution within the engine. This component plays a significant role in the efficient and reliable operation of heavy-duty trucks, contributing to overall engine performance and durability 1.

Basic Concepts of Piston Pins

A piston pin, also known as a wrist pin, is a cylindrical component that connects the piston to the connecting rod in an internal combustion engine. Its primary function is to allow the piston to move up and down within the cylinder while the connecting rod converts this linear motion into rotational motion at the crankshaft. The piston pin contributes to the engine’s performance and efficiency by ensuring smooth and precise movement of the piston, which is crucial for maintaining combustion efficiency and reducing wear on engine components 2.

Purpose of the Cummins 3064304 Piston Pin

The Cummins 3064304 Piston Pin is specifically engineered to connect the piston to the connecting rod in Cummins engines. This connection allows for the transfer of forces generated during combustion from the piston to the connecting rod, which then drives the crankshaft. The piston pin’s design enables it to accommodate the lateral forces exerted on the piston during engine operation, ensuring that the piston remains aligned within the cylinder and operates smoothly 3.

Key Features of the Cummins 3064304 Piston Pin

The Cummins 3064304 Piston Pin is characterized by several design and material features that enhance its performance and durability. These include precision machining to ensure accurate fit and function, heat treatment to increase strength and resistance to wear, and surface coatings that reduce friction and protect against corrosion. These features collectively contribute to the piston pin’s ability to withstand the high stresses and temperatures encountered in heavy-duty truck engines.

Benefits of Using the Cummins 3064304 Piston Pin

Utilizing the Cummins 3064304 Piston Pin offers several advantages. These include improved engine efficiency due to reduced friction between the piston and connecting rod, enhanced durability resulting from its robust design and materials, and increased reliability under the demanding conditions typical of heavy-duty truck operation. The piston pin’s design also contributes to smoother engine operation and reduced maintenance requirements.

Installation and Maintenance

Proper installation of the Cummins 3064304 Piston Pin is crucial for ensuring its optimal performance and longevity. This involves adhering to specified torque settings and alignment procedures to secure the piston pin in place and ensure it operates within the designed parameters. Regular maintenance, including inspection for wear and proper lubrication, is recommended to preserve the piston pin’s condition and functionality over time.

Troubleshooting Common Issues

Common issues associated with piston pins may include excessive wear, unusual noise, or failure. These problems can often be traced to improper installation, insufficient lubrication, or operational stresses exceeding the component’s design limits. Troubleshooting steps may involve inspecting the piston pin and surrounding components for signs of wear or damage, ensuring proper lubrication, and verifying that installation procedures were followed correctly.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the heavy-duty truck industry. The company’s commitment to advancing technology and meeting the needs of its customers underscores its position as a leader in the field.

Piston Pin Compatibility with Cummins Engines

The Cummins part 3064304, a Piston Pin, is designed to fit seamlessly within several of Cummins’ engine models. This part is integral to the engine’s operation, ensuring the piston moves smoothly within the cylinder. Here is a detailed look at its compatibility with specific Cummins engines:

G855

The Piston Pin 3064304 is compatible with the G855 engine. This engine is known for its robust design and efficiency, making it a popular choice in various applications. The pin’s precision engineering ensures it fits perfectly within the G855’s piston assembly, contributing to the engine’s overall performance and longevity.

N14 CELECT PLUS and N14 MECHANICAL

Both the N14 CELECT PLUS and N14 MECHANICAL engines benefit from the use of the Piston Pin 3064304. These engines are renowned for their reliability and power, often used in heavy-duty applications. The pin’s design allows for smooth operation and reduced wear, enhancing the engine’s efficiency and durability.

QSN14 CM876 N103

The Piston Pin 3064304 is also suitable for the QSN14 CM876 N103 engine. This engine model is engineered for high performance and is often utilized in demanding environments. The pin’s compatibility with this engine ensures that it can withstand the rigors of continuous operation, providing stability and reliability.

Each of these engines relies on the precision and quality of the Piston Pin 3064304 to maintain optimal performance. Cummins’ commitment to engineering excellence ensures that this part fits perfectly within the specified engine models, contributing to their overall efficiency and longevity.

Understanding the Role of Part 3064304 Piston Pin in Engine Systems

The part 3064304 Piston Pin is an essential component in the intricate network of an engine system. It serves as a pivotal connection point between the piston and the connecting rod, facilitating the smooth transfer of force from the combustion process to the crankshaft. This transfer is fundamental for the engine’s operation, as it converts the linear motion of the piston into rotational motion that powers the vehicle.

In the context of a Cylinder Head, the piston pin’s role becomes even more significant. The cylinder head houses the valves and intake and exhaust ports, which are critical for the engine’s breathing. The efficient movement of the piston, guided by the piston pin, ensures that the valves open and close at the correct times, maintaining the engine’s performance and efficiency.

When considering a Cylinder Kit or an Engine Piston Kit, the inclusion of a high-quality piston pin like part 3064304 is vital. These kits are designed to improve engine performance, durability, and efficiency. The piston pin’s ability to withstand high loads and temperatures contributes to the overall reliability of the engine, especially in high-performance applications.

In the realm of Performance Parts and EBM-Performance Parts, the piston pin’s significance is heightened. These parts are often subjected to extreme conditions, requiring components that can endure higher stresses and temperatures. Part 3064304, with its robust design, plays a key role in enhancing the performance and longevity of these high-performance engine systems.

The interaction between the piston pin and other components like the Injector and Turbocharger is also noteworthy. The injector’s precise fuel delivery relies on the consistent and smooth operation of the piston, which is directly influenced by the piston pin. Similarly, in turbocharged engines, where air is forced into the combustion chamber, the piston pin’s role in handling increased pressures and forces becomes even more pronounced.

Conclusion

In summary, part 3064304 Piston Pin is a fundamental component in various engine systems, contributing to the efficient and reliable operation of the engine. Its interaction with other components like the cylinder head, piston kit, and performance parts underscores its importance in both standard and high-performance engine applications.

-

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.