This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

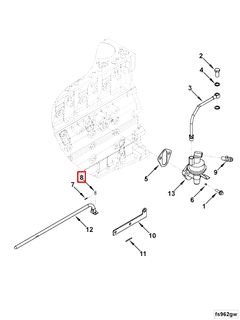

The Cummins 4928967 Pivot Pin is a component used in heavy-duty truck operations. It plays a role in the mechanical system of trucks by facilitating smooth and efficient movement of certain parts. Understanding its function and significance within the broader context of truck components is important for maintaining and optimizing truck performance 3.

Basic Concepts of Pivot Pins

Pivot pins are cylindrical components used in mechanical systems to allow rotational movement between two parts. They are integral to the operation of various machinery, including heavy-duty trucks, by enabling parts to pivot or rotate around a fixed point. This rotational capability is crucial for the functioning of many mechanical systems, allowing for efficient operation and movement 1.

Purpose of the Cummins 4928967 Pivot Pin

The Cummins 4928967 Pivot Pin is designed to facilitate the rotational movement of specific components within a truck’s mechanical system. Its function is to provide a stable yet flexible connection point, allowing parts to move as needed while maintaining structural integrity and alignment. This contributes to the overall efficiency and reliability of the truck’s operation 2.

Key Features

The Cummins 4928967 Pivot Pin is constructed with features that enhance its performance and durability. It is made from high-quality materials that offer resistance to wear and corrosion. Its dimensions are precisely engineered to ensure a proper fit and function within the truck’s mechanical system. Additionally, it may include unique design elements that further improve its performance under various operating conditions 4.

Benefits

The Cummins 4928967 Pivot Pin offers several advantages. It contributes to improved truck performance by ensuring smooth and efficient operation of connected components. Its durable construction promotes longevity, reducing the need for frequent replacements. Additionally, its reliable function enhances the overall reliability of the truck, supporting consistent operation under demanding conditions 3.

Installation Process

Installing the Cummins 4928967 Pivot Pin requires following a step-by-step process to ensure proper fitting. This may involve using specific tools to remove the old pivot pin, cleaning the installation area, and carefully inserting the new pivot pin. Best practices include ensuring the pivot pin is securely in place and aligned correctly to prevent issues during operation 1.

Maintenance and Troubleshooting

Regular maintenance practices can help prolong the life of the Cummins 4928967 Pivot Pin. This may include periodic inspections for signs of wear or damage, cleaning the pivot pin and surrounding areas, and lubricating as necessary. Common issues that may arise with pivot pins include wear, corrosion, or misalignment. Troubleshooting steps may involve inspecting the pivot pin and connected components, cleaning or replacing parts as needed, and ensuring proper alignment and fit 2.

Safety Considerations

When handling, installing, or maintaining the Cummins 4928967 Pivot Pin, it is important to observe safety guidelines and precautions. This includes wearing appropriate personal protective equipment, ensuring the truck is properly secured and the engine is off during installation or maintenance, and following all manufacturer recommendations and industry standards for safe handling and use 3.

Cummins Overview

Cummins Inc. is a well-established manufacturer of diesel engines and related technologies. With a history of innovation and commitment to quality, Cummins has built a reputation for producing reliable and high-performance components for various industries, including heavy-duty trucking. Their products are designed to meet stringent industry standards and provide efficient, durable solutions for demanding applications 4.

Pivot Pin 4928967 Compatibility with Cummins Engines

The Pivot Pin part number 4928967, manufactured by Cummins, is designed to fit seamlessly within the 4B3.9 and 6B5.9 engine families. This component is integral to the proper functioning of these engines, ensuring smooth operation and longevity.

4B3.9 Engine Family

In the 4B3.9 engine series, the Pivot Pin 4928967 plays a crucial role in maintaining the alignment and stability of various moving parts. Its precision engineering ensures that the engine components operate with minimal friction, thereby enhancing overall performance and reducing wear and tear.

6B5.9 Engine Family

Similarly, within the 6B5.9 engine family, the Pivot Pin 4928967 is essential for the precise movement and alignment of critical engine parts. This pin’s design allows for efficient load distribution and smooth rotational movements, which are vital for the engine’s efficiency and durability.

By integrating the Pivot Pin 4928967 into these engine families, Cummins ensures that the engines maintain their operational integrity and reliability over time.

Role of Part 4928967 Pivot Pin in Engine Systems

The 4928967 Pivot Pin is an essential component in various engine systems, facilitating smooth operation and efficient performance. In the context of a pump system, the pivot pin allows for the rotational movement necessary for the pump’s operation. This movement ensures that the pump can effectively draw in and expel fluids, maintaining the required pressure and flow rates within the engine.

In a fuel transfer system, the pivot pin plays a similarly important role. It enables the precise and controlled movement of components within the fuel transfer mechanism. This ensures that fuel is accurately metered and delivered to the engine, optimizing combustion efficiency and overall engine performance. The pivot pin’s reliable operation is fundamental to the consistent and efficient transfer of fuel, which is vital for the engine’s sustained operation under varying conditions 4.

Conclusion

The Cummins 4928967 Pivot Pin is a critical component in heavy-duty truck operations, ensuring the smooth and efficient movement of parts within the mechanical system. Its durable construction, precise engineering, and reliable function contribute to the overall performance and reliability of the truck. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

-

Brakes Brake Control and Driver Assistance Systems Function Regulation and Components, Konrad Reif Ed, Springer, 2014

↩ ↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010

↩ ↩ -

Automobile Vehicle Safety, George Peters, Barbara J Peters, CRC Press, 2002

↩ ↩ ↩ -

Automotive Mechatronics Operational and Practical Issues Volume 1, BT Fijalkowski, Springer, 2011

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.