This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

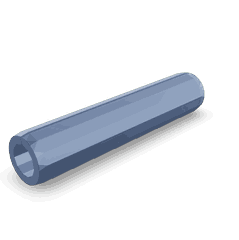

The Cummins 3033629 Roll Pin is a specialized component designed for use in heavy-duty truck systems. Its purpose is to secure various mechanical parts in place, ensuring the smooth operation of the truck’s systems. Understanding the role and significance of this part is important for maintaining the efficiency and reliability of heavy-duty trucks.

Basic Concepts of Roll Pins

Roll pins are cylindrical fasteners used in mechanical systems to hold components together. They function by being pressed into holes that pass through the parts to be joined, providing a secure fit without the need for additional fasteners. Roll pins are commonly used in applications where parts need to be aligned precisely and where vibration or movement could loosen traditional fasteners 1.

Purpose of the Cummins 3033629 Roll Pin

The Cummins 3033629 Roll Pin plays a specific role in the operation of heavy-duty trucks. It is designed to secure components within the truck’s engine and transmission systems, ensuring that parts remain aligned and function correctly under the demanding conditions of heavy-duty operations. This roll pin is associated with critical systems that require precise component alignment and secure fastening 2.

Key Features

The Cummins 3033629 Roll Pin is characterized by several key features that enhance its functionality. It is made from high-quality materials that provide durability and resistance to wear. The dimensions of the roll pin are precisely engineered to fit specific applications, ensuring a secure and reliable connection. Additionally, the design of the roll pin may include features that facilitate easy installation and removal when necessary 3.

Benefits

Using the Cummins 3033629 Roll Pin offers several benefits in truck operations. Its design contributes to improved reliability by securely holding components in place, even under the stress of heavy-duty use. The durability of the roll pin ensures long-term performance, reducing the need for frequent replacements. Furthermore, the precise engineering of the roll pin enhances the overall performance of the truck’s systems by maintaining component alignment and integrity.

Installation Process

Proper installation of the Cummins 3033629 Roll Pin is important for ensuring its effectiveness. The installation process involves pressing the roll pin into the designated holes in the components it is meant to secure. This requires the use of appropriate tools to ensure the roll pin is seated correctly without damage. Careful alignment of the components before installation is also important to achieve the desired secure fit.

Common Issues and Troubleshooting

Common issues with the Cummins 3033629 Roll Pin may include improper seating, which can lead to component misalignment or failure. Troubleshooting these issues involves inspecting the roll pin and the components for correct alignment and secure fit. If the roll pin is found to be improperly seated, it may need to be removed and reinstalled, ensuring that all components are correctly aligned before pressing the roll pin into place.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3033629 Roll Pin, regular inspection is recommended. This includes checking for signs of wear or damage that could affect its securing ability. Replacement guidelines should be followed if the roll pin shows signs of significant wear or if it has been damaged. Keeping the roll pin and its associated components clean and free from debris can also contribute to its longevity.

Compatibility and Application

The Cummins 3033629 Roll Pin is designed for use in various truck models and systems, demonstrating its versatility and widespread application in the heavy-duty truck industry. Its compatibility with different systems makes it a valuable component for maintaining the efficiency and reliability of heavy-duty trucks.

Manufacturer Overview - Cummins

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industry, known for its wide range of products and strong reputation for quality and reliability. With a history of innovation and commitment to excellence, Cummins provides components that are designed to meet the demanding requirements of heavy-duty applications, ensuring the performance and durability of trucks in various industries.

Cummins Engine Part 3033629: Roll Pin Compatibility

The Cummins part 3033629, a Roll Pin, is a critical component used in various Cummins engine models. This roll pin is designed to provide secure and reliable connections within the engine assembly, ensuring that moving parts remain properly aligned and function as intended. Below is a detailed breakdown of the engines that utilize this part:

B5.6 and B6.7 Series Engines

- B5.6 CM2670 B152B

- B6.7 CM2670 B153B

These engines, part of the B series, are commonly used in medium-duty applications. The roll pin 3033629 is integral in maintaining the alignment of various engine components, ensuring smooth operation and longevity.

G Series Engines

- G855

- GTA38 G CMEICS G116C

The G series engines, often found in heavy-duty applications, rely on the roll pin 3033629 to secure critical parts within the engine assembly. This ensures that the engine can withstand the rigors of heavy-duty use.

ISB Series Engines

- ISB CM2150

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

- ISBE CM2150

- ISBE4 CM850

The ISB series engines, which are widely used in both medium and heavy-duty applications, incorporate the roll pin 3033629 to maintain the integrity of their moving parts. This ensures optimal performance and reliability across various operational conditions.

QSB Series Engines

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

The QSB series engines, known for their use in agricultural and construction equipment, depend on the roll pin 3033629 to secure various components. This ensures that the engine can handle the demanding environments these applications often present.

QSK Series Engines

- QSK19 CM850 MCRS

- QSK38 CM2150 MCRS

The QSK series engines, designed for heavy-duty applications, utilize the roll pin 3033629 to maintain the alignment and stability of critical engine parts. This ensures that the engine can operate efficiently and reliably under heavy loads.

K Series Engines

- K19

- K38

- K50

The K series engines, often used in military and specialized applications, incorporate the roll pin 3033629 to ensure that the engine components remain securely aligned, providing the necessary performance and durability for these demanding applications.

KTA Series Engines

- KTA19GC

- KTA38GC CM558

The KTA series engines, known for their use in power generation and marine applications, rely on the roll pin 3033629 to maintain the integrity of their moving parts. This ensures that the engine can operate reliably in these critical applications.

The roll pin 3033629 is a versatile and essential component in Cummins engines, ensuring that various parts remain securely aligned and function correctly. Its use across a wide range of engine models highlights its importance in maintaining engine performance and reliability.

Role of Part 3033629 Roll Pin in Engine Systems

The part 3033629 Roll Pin is an essential component in various engine systems, facilitating smooth operation and efficient performance. Its applications span across multiple subsystems, ensuring the integrity and functionality of the engine.

Adapter Crank Mounting and Alternator Mounting

In the adapter crank mounting and alternator mounting systems, the Roll Pin secures the connection between the crankshaft and the alternator. This ensures that the alternator is properly aligned and can efficiently convert mechanical energy into electrical energy to power the vehicle’s electrical systems.

Block and Cylinder

Within the engine block and cylinder assembly, the Roll Pin plays a role in maintaining the precise alignment of components. It helps in securing piston pins within the connecting rods, ensuring that the pistons move smoothly within the cylinders without excessive wear or misalignment.

Compressor and Refrigerant Systems

In compressor and refrigerant systems, the Roll Pin is used to secure the connection between the compressor shaft and the refrigerant compressor support. This ensures that the compressor operates efficiently, maintaining the proper flow of refrigerant and thus the cooling performance of the system.

Damper and Vibration Systems

The Roll Pin is integral in damper and vibration systems, particularly in the EBM-damper and viscous vibration damper. It secures the connection between the damper and the engine crankshaft, allowing the damper to effectively absorb vibrations and reduce engine noise and wear.

Drive and Fan Systems

In drive and fan systems, the Roll Pin ensures that the fan is properly attached to the engine crankshaft. This allows the fan to operate efficiently, providing the necessary airflow for engine cooling and maintaining optimal operating temperatures.

Flywheel Housing and Generator

The Roll Pin is used in the flywheel housing to secure the connection between the flywheel and the engine crankshaft. This ensures that the flywheel can store rotational energy efficiently, smoothing out the engine’s power delivery. In the generator system, it secures the main generator adapter, ensuring stable electrical output.

Filter Systems

In filter systems, such as the fuel filter, full flow oil filter, and lubricating oil filter, the Roll Pin is used to secure filter heads and housings. This ensures that filters are properly installed and can effectively remove contaminants from the fuel and oil, maintaining engine health.

Lubricating Oil Systems

Within lubricating oil systems, the Roll Pin helps in securing the lubricating oil filter head, ensuring that the filter is correctly positioned to provide clean oil to the engine components. This is vital for reducing friction and wear within the engine.

Ignition and Throttle Systems

In ignition and throttle systems, the Roll Pin is used in the throttle position sensor housing and valve throttle assembly. It ensures that the throttle position sensor is accurately aligned, providing precise data to the engine control unit for optimal fuel delivery and engine performance.

Overall, the part 3033629 Roll Pin is a versatile component that enhances the reliability and performance of various engine systems by ensuring secure and precise connections between critical components.

Conclusion

The Cummins 3033629 Roll Pin is a critical component in the maintenance and operation of heavy-duty trucks. Its role in securing various mechanical parts ensures the smooth and efficient operation of the truck’s systems. Understanding its purpose, features, and benefits is essential for maintaining the reliability and performance of heavy-duty trucks. Proper installation, regular maintenance, and awareness of common issues are key to maximizing the effectiveness of this part in heavy-duty applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.