This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3020825 Plain Pipe Coupling is a component designed to facilitate the connection of different sections within a truck’s piping system. Its role is significant in ensuring the smooth operation of fluid systems in commercial trucks, contributing to the overall efficiency and reliability of the vehicle.

Basic Concepts of Plain Pipe Couplings

Plain pipe couplings are mechanical devices used to join two sections of pipe together. They function by providing a secure and leak-proof connection, allowing for the transfer of fluids or gases between the connected pipes. These couplings are commonly used in various fluid systems, including hydraulic, pneumatic, and fuel systems, to ensure continuity and integrity in the piping network 1.

Purpose of the 3020825 Plain Pipe Coupling

The 3020825 Plain Pipe Coupling serves to connect different sections of piping systems in trucks. It plays a role in maintaining the integrity of the fluid pathways by providing a reliable connection point. This ensures that fluids can be transported efficiently throughout the system without leakage or disruption.

Key Features

The 3020825 Plain Pipe Coupling is characterized by several key features that enhance its performance. It is constructed from durable materials, ensuring longevity and resistance to wear and corrosion. The design includes precise fitting elements that allow for a secure connection, minimizing the risk of leaks. Additionally, it may feature unique attributes such as anti-vibration properties or easy-to-use locking mechanisms that simplify installation and maintenance.

Benefits

The 3020825 Plain Pipe Coupling offers several benefits that contribute to its effectiveness in truck applications. These include improved system efficiency through secure connections, enhanced durability due to its material composition, ease of installation thanks to its design features, and maintenance advantages such as simplified inspection and cleaning procedures.

Installation Process

Installing the 3020825 Plain Pipe Coupling involves several steps to ensure a proper and secure connection. First, the ends of the pipes to be joined should be cleaned and prepared. The coupling is then positioned over the pipe ends, and any locking mechanisms are engaged to secure the connection. Tools required may include wrenches for tightening and cleaning brushes for preparation.

Maintenance Tips

To ensure the longevity and optimal performance of the 3020825 Plain Pipe Coupling, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, cleaning the coupling and surrounding areas to prevent debris accumulation, and checking the tightness of the connection to prevent leaks.

Troubleshooting Common Issues

Common issues with the 3020825 Plain Pipe Coupling may include leaks or misalignment. To address these problems, it is important to inspect the coupling for any visible damage or wear. Ensuring that the coupling is properly aligned and securely fastened can often resolve these issues. In cases of persistent problems, replacement of the coupling may be necessary.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial truck, bus, construction, agricultural, and power generation markets. The company is known for its commitment to reliability, performance, and customer satisfaction in the commercial truck industry 2.

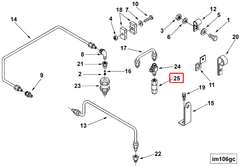

Cummins Engine Part 3020825: Plain Pipe Coupling

The Cummins Plain Pipe Coupling part 3020825 is a critical component in the engine systems of various Cummins engines, including the K19 and V903 series. This coupling is essential for the seamless connection of pipes within the engine’s exhaust and fluid systems, ensuring efficient operation and durability.

K19 Engine Series

In the K19 engine series, the Plain Pipe Coupling part 3020825 is utilized to connect various exhaust and fluid pipes. Its design ensures a tight and secure fit, which is crucial for maintaining the integrity of the engine’s exhaust and cooling systems. This coupling helps in reducing leaks and ensuring that the engine operates at optimal efficiency.

V903 Engine Series

Similarly, in the V903 engine series, the Plain Pipe Coupling part 3020825 plays a vital role in connecting pipes within the engine’s exhaust and fluid systems. The coupling’s robust construction and precise fit are essential for the V903 engines, which are known for their high performance and reliability. This part ensures that the engine’s systems function smoothly, contributing to the overall efficiency and longevity of the engine.

Grouping of Engines

Both the K19 and V903 engine series benefit from the use of the Plain Pipe Coupling part 3020825. This part is designed to fit seamlessly into the engine systems, providing a reliable connection that is essential for the proper functioning of the engine. The coupling’s compatibility with these engines ensures that they can operate efficiently and reliably, making it a crucial component in the maintenance and performance of these engines.

Role of Part 3020825 Plain Pipe Coupling in Engine Systems

The 3020825 Plain Pipe Coupling is an essential component in various engine systems, facilitating the secure and efficient connection of different parts. Here’s how it integrates with several key components:

Aftercooler Plumbing

In aftercooler systems, the Plain Pipe Coupling ensures a reliable connection between the aftercooler and the associated plumbing. This connection is vital for maintaining the integrity of the cooling process, allowing for efficient temperature regulation of the compressed air before it enters the engine.

Check Valve Mounting

When mounting check valves, the Plain Pipe Coupling provides a stable and leak-proof connection. This is important for the proper functioning of the check valve, which prevents backflow and ensures that fluid or air moves in the correct direction within the system.

F.D Tubing Mounting

For fuel drain (F.D) tubing, the Plain Pipe Coupling offers a secure attachment point. This ensures that the fuel drain system operates without leaks, maintaining the safety and efficiency of the fuel management system.

Fuel Drain Connection

In fuel drain connections, the Plain Pipe Coupling plays a role in creating a tight seal. This prevents any fuel leakage, which is essential for both the performance and safety of the engine system.

Fuel Drain Tubing Mounting

Similar to the F.D tubing mounting, the Plain Pipe Coupling in fuel drain tubing mounting ensures that the tubing is firmly and safely connected. This is crucial for the effective drainage of fuel, preventing any buildup that could lead to engine issues.

Fuel Tubing

Within the fuel tubing network, the Plain Pipe Coupling provides a consistent and secure connection. This is important for maintaining the pressure and flow of fuel to the engine, ensuring optimal performance.

Intake Manifold

The Plain Pipe Coupling is used in the intake manifold to connect various tubes and components. This ensures that air enters the engine smoothly and efficiently, contributing to better combustion and engine performance.

Manifold Press Mounting Tube

For manifold pressure mounting tubes, the Plain Pipe Coupling ensures a robust connection. This is important for accurately measuring manifold pressure, which is a key parameter in engine management.

Manifold Press Tube

In the manifold press tube system, the Plain Pipe Coupling provides a reliable connection. This ensures that pressure readings are accurate, allowing for precise engine control.

Manifold Pressure Mounting

When mounting manifold pressure components, the Plain Pipe Coupling ensures a secure fit. This is essential for the accurate monitoring of manifold pressure, which is critical for engine performance and diagnostics.

Manifold Pressure Tube

The Plain Pipe Coupling in manifold pressure tubes ensures that these tubes are firmly connected. This is important for the consistent and accurate transmission of pressure data within the engine system.

Manifold Tube Mounting

For manifold tube mounting, the Plain Pipe Coupling provides a stable connection. This ensures that the manifold tubes are securely in place, contributing to the overall efficiency of the engine’s air intake system.

Mounting and Fuel Bypass Tube

In fuel bypass tube mounting, the Plain Pipe Coupling ensures a leak-free connection. This is important for the proper functioning of the fuel bypass system, which helps maintain consistent fuel pressure.

Mounting and Manifold Tube

For manifold tube mounting, the Plain Pipe Coupling ensures a secure and stable connection. This is vital for the efficient operation of the manifold system, ensuring that air is properly distributed within the engine.

Mtg. Fuel Drain Tubing

In the context of fuel drain tubing mounting, the Plain Pipe Coupling ensures a reliable connection. This is essential for the safe and efficient drainage of fuel, preventing any potential leaks or buildup.

Mtg. Manifold Pressure Tubing

For manifold pressure tubing mounting, the Plain Pipe Coupling provides a secure attachment. This ensures that the pressure tubing is firmly in place, allowing for accurate pressure readings and efficient engine operation.

Plumbing

In general plumbing applications within the engine system, the Plain Pipe Coupling ensures that all connections are tight and leak-free. This is important for the overall integrity and performance of the engine’s fluid and air systems.

Fuel Pump Plumbing

In fuel pump plumbing, the Plain Pipe Coupling ensures a secure connection between the fuel pump and the associated tubing. This is essential for maintaining the proper flow of fuel to the engine, ensuring consistent performance.

Fuel Supply Plumbing

For fuel supply plumbing, the Plain Pipe Coupling provides a reliable connection. This ensures that the fuel supply system operates without leaks, contributing to the engine’s efficiency and safety.

AFC (Air Flow Control) Plumbing

In AFC plumbing, the Plain Pipe Coupling ensures that all connections are secure and leak-free. This is important for the precise control of air flow within the engine, which is crucial for optimal performance.

Pressure Tube Manifold

In pressure tube manifold systems, the Plain Pipe Coupling ensures that all connections are firm and reliable. This is essential for the accurate measurement and control of pressure within the engine system.

Tubing

Across various tubing applications, the Plain Pipe Coupling provides a consistent and secure connection. This is important for the efficient transmission of fluids and air within the engine system, ensuring smooth operation and performance.

Manifold Pressure

In manifold pressure systems, the Plain Pipe Coupling ensures that all connections are secure. This is vital for the accurate monitoring and control of manifold pressure, which is a key factor in engine management.

Valve Check

For check valve applications, the Plain Pipe Coupling ensures a reliable connection. This is important for the proper functioning of the check valve, which prevents backflow and ensures that fluids or air move in the correct direction within the system.

Conclusion

The Cummins 3020825 Plain Pipe Coupling is a vital component in the engine systems of commercial trucks, ensuring the efficient and reliable connection of various piping systems. Its robust construction, precise fitting elements, and ease of installation make it an essential part for maintaining the integrity and performance of the engine’s fluid and air systems. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall efficiency and reliability of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.