This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

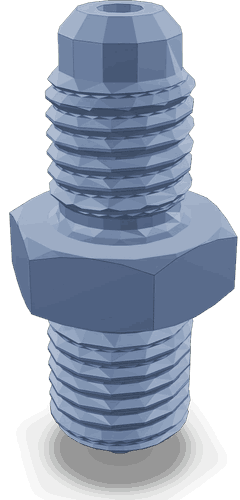

The Cummins 3164818 Pipe Adapter is a component designed to facilitate the connection between different pipe sizes and types within the fluid systems of commercial trucks. Its role is significant in ensuring the seamless operation of these systems, contributing to the overall efficiency and reliability of the vehicle.

Basic Concepts of Pipe Adapters

Pipe adapters are devices used to connect pipes of different sizes or types, allowing for the integration of various components within a fluid system. They play a role in maintaining the integrity of the system by ensuring that fluid flow is uninterrupted and that connections are secure. Adapters are essential in scenarios where standard fittings do not align, providing a solution to connect disparate parts effectively 1.

Purpose of the 3164818 Pipe Adapter

This Cummins part is specifically designed to play a role in the fluid systems of trucks. It enables the connection between different sections of the system, ensuring that fluids such as coolant, fuel, or hydraulic fluid can flow without interruption. This adapter is applied in situations where the standard pipe fittings do not match, providing a bridge between components and contributing to the system’s overall functionality.

Key Features

The 3164818 is constructed from materials that offer durability and resistance to the pressures and temperatures encountered in truck fluid systems. Its design specifications include precise dimensions and threading to ensure a secure fit. Unique attributes such as corrosion resistance and ease of installation enhance its functionality, making it a reliable component for truck maintenance and repair.

Benefits of Using the 3164818 Pipe Adapter

Utilizing this part offers several advantages. It contributes to improved system efficiency by ensuring a secure and leak-free connection. Its durable construction enhances the longevity of the fluid system, while its design facilitates ease of installation, reducing downtime during maintenance procedures.

Installation Process

Installing the 3164818 involves several steps to ensure a proper fit and function. The process includes preparing the connection points, applying any necessary sealants, and using the appropriate tools to secure the adapter in place. Detailed instructions and the use of compatible tools are recommended to achieve a successful installation.

Common Issues and Troubleshooting

Common problems with the 3164818 may include leaks, improper fitting, or damage to the adapter itself. Troubleshooting these issues involves checking the connections for tightness, inspecting the adapter for signs of wear or damage, and ensuring that the correct sealants and tools were used during installation. Solutions may range from re-tightening connections to replacing the adapter if it is found to be faulty.

Maintenance Tips

Regular maintenance of the 3164818 is recommended to ensure its longevity and optimal performance. This includes periodic inspection for signs of wear or corrosion, cleaning the adapter and its connections, and replacing any damaged components. Adhering to these practices helps maintain the integrity of the truck’s fluid systems.

Safety Considerations

When installing or maintaining the 3164818, it is important to observe safety guidelines. This includes wearing appropriate personal protective equipment, ensuring the system is depressurized before beginning work, and following manufacturer recommendations for installation and maintenance. These precautions help prevent accidents and ensure the safe operation of the vehicle.

About Cummins

Cummins Inc. is a corporation known for designing, manufacturing, and distributing engines and related technologies. With a history of innovation and a broad product range, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its components, including the 3164818 Pipe Adapter.

Role of Part 3164818 Pipe Adapter in Engine Systems

This part is integral to the efficient operation of various engine systems, particularly when interfacing with components such as the Hydraulic Bolt Tensioner.

In hydraulic systems, the Pipe Adapter ensures a secure and leak-proof connection between the Hydraulic Bolt Tensioner and the engine’s hydraulic lines. This connection is essential for maintaining the precise fluid pressure required for the tensioner to function correctly. The adapter’s design allows for easy installation and removal, facilitating maintenance and repairs without requiring complex tools or procedures.

Furthermore, the Pipe Adapter plays a significant role in regulating the flow of hydraulic fluid. By providing a consistent and reliable pathway for the fluid, it helps in maintaining the optimal performance of the Hydraulic Bolt Tensioner. This, in turn, ensures that the tensioner can effectively manage the tension in the engine’s components, such as timing belts or chains, contributing to the overall stability and efficiency of the engine.

Additionally, the adapter’s robust construction ensures durability under high pressure and temperature conditions typically found in engine compartments. This reliability is vital for the long-term performance and safety of the engine system.

Conclusion

In summary, the 3164818 Pipe Adapter is a key component in ensuring the seamless integration and operation of the Hydraulic Bolt Tensioner within the engine system. Its role in maintaining fluid integrity, facilitating easy maintenance, and ensuring durable connections underscores its importance in the overall functionality of the engine.

-

Richards, Paul, and Jim Barker. Automotive Fuels Reference Book. SAE International, 2023.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.