This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

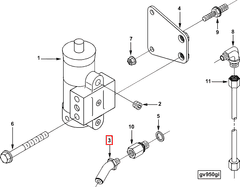

The Cummins 3357496 Pipe Connector is a specialized component designed for use in commercial trucks. Its purpose is to facilitate the secure and efficient transfer of fluids within the truck’s systems. This connector plays a role in maintaining the operational integrity of the vehicle’s fluid systems, ensuring that liquids or gases are transported reliably and without leakage.

Basic Concepts of Pipe Connectors

Pipe connectors are components used in fluid systems to join pipes and other equipment, allowing for the transfer of liquids or gases. In automotive applications, these connectors are vital for maintaining the functionality of various systems, such as fuel lines, coolant systems, and hydraulic systems. They ensure that connections are secure, leak-free, and capable of withstanding the pressures and temperatures encountered in vehicle operations 1.

Purpose of the 3357496 Pipe Connector

This Cummins part is specifically designed to play a role in the fluid systems of commercial trucks. It functions by providing a reliable connection point for pipes and other components, ensuring that fluids are transferred efficiently throughout the system. This connector is integral to maintaining the performance and reliability of the truck’s fluid systems, contributing to overall vehicle efficiency and durability.

Key Features

The 3357496 boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The design includes precise threading and sealing mechanisms to provide a secure connection. Additionally, the connector may feature unique attributes such as reinforced joints or specialized coatings to further improve its longevity and reliability in demanding environments.

Benefits

The advantages of using this part include improved efficiency and reliability in the truck’s fluid systems. By ensuring secure and leak-free connections, this component helps maintain system integrity and performance. Fleet operators may also experience cost savings due to reduced maintenance needs and increased durability of the connector, leading to lower overall operational costs.

Installation Process

Installing the 3357496 requires careful attention to detail to ensure a secure and effective connection. The process involves preparing the pipe ends, applying any necessary sealants, and then threading the connector onto the pipe. Tools such as wrenches may be required to tighten the connection properly. Following best practices, such as ensuring all surfaces are clean and free of debris, will help achieve a reliable connection.

Maintenance Tips

Regular maintenance of the 3357496 is important to ensure its longevity and optimal performance. This includes periodic inspections for signs of wear or corrosion, and cleaning the connector to remove any buildup that could affect its function. Following manufacturer recommendations for inspection intervals and maintenance procedures will help keep the connector in good condition.

Troubleshooting Common Issues

Common problems associated with pipe connectors, such as leaks or corrosion, can often be addressed through proper troubleshooting. Identifying the source of a leak may involve checking for loose connections or damaged seals. Corrosion can be mitigated by ensuring the connector is made from corrosion-resistant materials and is properly maintained. Addressing these issues promptly can help maintain the efficiency and reliability of the truck’s fluid systems.

Compatibility and Applications

The 3357496 is designed for use in specific types of trucks and fluid systems. It is commonly applied in applications where reliable fluid transfer is critical to vehicle performance. Understanding the compatibility of this connector with various systems ensures it is used effectively and contributes to the overall functionality of the truck.

Safety Considerations

When working with the 3357496, it is important to observe safety protocols and precautions. This includes handling the connector with care to avoid damage, and being aware of potential hazards such as fluid leaks or pressurized systems. Following manufacturer guidelines and safety procedures will help ensure a safe working environment.

Environmental Impact

The use of the 3357496 may have environmental considerations, particularly regarding its materials and disposal. Eco-friendly features, such as the use of recyclable materials or designs that minimize waste, can contribute to reducing the environmental impact. Additionally, proper disposal and recycling procedures for the connector can help mitigate its environmental footprint.

About Cummins

Cummins Inc. is a leading manufacturer in the automotive industry, known for its innovative products and commitment to quality. With a history of developing reliable and efficient components for commercial vehicles, Cummins continues to advance technology and set industry standards. The company’s extensive product range includes a variety of parts designed to enhance the performance and durability of trucks and other heavy-duty vehicles.

Conclusion

The Cummins 3357496 Pipe Connector is a vital component in the fluid systems of commercial trucks, ensuring efficient and reliable fluid transfer. Its high-quality construction, key features, and benefits make it a valuable asset for fleet operators. Proper installation, maintenance, and troubleshooting are essential for maximizing its performance and longevity. Understanding its compatibility and applications, along with observing safety and environmental considerations, further enhances its value in the automotive industry.

-

Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak. Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.