This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

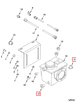

The 3394834 Reducing Pipe Bushing, a component manufactured by Cummins, is designed to facilitate the connection between pipes of different diameters in heavy-duty truck systems. This part ensures the efficient and smooth flow of fluids or gases within the truck’s system. Cummins, a well-established manufacturer in the automotive industry, is known for its commitment to quality and innovation in producing reliable and durable components.

Function and Operation

The Reducing Pipe Bushing operates by bridging the gap between pipes of varying diameters, allowing for a seamless connection. This component ensures that the flow of fluids or gases is uninterrupted and maintains system integrity. By accommodating different pipe sizes, it plays a role in maintaining the efficiency and reliability of the truck’s system.

Key Features

The 3394834 Reducing Pipe Bushing is characterized by several key features that enhance its performance. It is constructed from durable materials, ensuring longevity and resistance to wear and tear. The design of the bushing is tailored to fit securely within the piping system, minimizing the risk of leaks. Additionally, its unique characteristics, such as precision machining and robust construction, contribute to its effectiveness in heavy-duty applications.

Benefits

Utilizing the Reducing Pipe Bushing in truck maintenance and operation offers several advantages. It contributes to improved system efficiency by ensuring a smooth flow of fluids or gases. The design of the bushing helps in reducing leakage, which can lead to system inefficiencies and potential damage. Furthermore, its durable construction enhances the overall durability of the truck’s system, reducing the need for frequent replacements or repairs.

Installation Process

Proper installation of the Reducing Pipe Bushing is crucial for its effective operation. The process involves carefully aligning the bushing with the pipes it connects, ensuring a snug fit. It is important to follow manufacturer guidelines to avoid common pitfalls such as misalignment or over-tightening, which can compromise the integrity of the connection.

Maintenance and Troubleshooting

Regular maintenance of the Reducing Pipe Bushing is recommended to ensure its continued effectiveness. This includes checking for signs of wear or damage and ensuring that the connections remain secure. Common issues may include leaks or reduced flow efficiency, which can often be addressed by re-tightening connections or replacing worn components.

Compatibility and Applications

The 3394834 Reducing Pipe Bushing is designed for use in various truck models and systems, offering versatility in application. Its compatibility with other components is a key consideration in ensuring system integrity and efficiency.

Safety Considerations

When handling and installing the Reducing Pipe Bushing, it is important to observe safety guidelines and precautions. This includes the use of personal protective equipment (PPE) and adhering to safe work practices to prevent injuries and ensure a secure installation.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, with a history of producing high-quality and innovative components. The company’s product range includes a variety of parts designed for heavy-duty applications, reflecting Cummins’ commitment to quality and customer satisfaction.

Reducing Pipe Bushing (Part 3394834) Compatibility with Cummins Engines

The Reducing Pipe Bushing, identified by part number 3394834 and manufactured by Cummins, is a crucial component designed to facilitate the connection between different pipe sizes in various engine systems. This part is engineered to ensure a secure and leak-proof connection, which is essential for maintaining the integrity of the engine’s exhaust and fluid systems.

G8.3 and G855 Engines

The Reducing Pipe Bushing is compatible with the G8.3 and G855 engines. These engines are known for their robust design and efficiency, often used in heavy-duty applications. The bushing ensures that the connections between the exhaust and other components are properly aligned, reducing the risk of leaks and maintaining optimal performance.

G855 CM558 and GTA855 CM558 (CM2358) G101 Engines

For the G855 CM558 and GTA855 CM558 (CM2358) G101 engines, the Reducing Pipe Bushing is essential for maintaining the structural integrity of the exhaust system. These engines are part of the advanced Cummins lineup, designed for high-performance and durability. The bushing’s precision fit ensures that the exhaust system components are securely connected, which is critical for the efficient operation of these engines.

KTA19GC Engine

The KTA19GC engine also benefits from the use of the Reducing Pipe Bushing. This engine is known for its reliability and power, often used in industrial and marine applications. The bushing helps in creating a seamless transition between different pipe sizes, ensuring that the engine’s exhaust system operates smoothly and efficiently.

N14 G Engine

Lastly, the N14 G engine is another model that utilizes the Reducing Pipe Bushing. This engine is renowned for its strength and longevity, commonly found in heavy-duty trucks and construction equipment. The bushing’s role in this engine is to maintain the connection integrity, preventing any potential leaks and ensuring that the engine performs at its best.

Role of Part 3394834 Reducing Pipe Bushing in Engine Systems

The 3394834 Reducing Pipe Bushing is instrumental in ensuring seamless integration and operation within various engine systems. It facilitates the connection between different components, allowing for efficient fluid dynamics and structural integrity.

In the oil fill arrangement, the Reducing Pipe Bushing ensures a secure connection between the oil fill port and the oil tank, preventing leaks and maintaining system pressure. This is essential for consistent oil delivery to the engine’s moving parts 1.

Within the oil level gauge system, it acts as a transition fitting, enabling accurate measurement of the oil level. This ensures that the engine maintains optimal lubrication without overfilling, which could lead to inefficiencies or damage 2.

In the manifold and exhaust systems, the Reducing Pipe Bushing helps in managing the flow of gases. By providing a smooth transition between different pipe diameters, it reduces turbulence and pressure drops, enhancing overall engine performance 3.

For the fuel control module, this component ensures a tight seal between the fuel lines, preventing fuel leaks and maintaining consistent fuel pressure. This is vital for the precise delivery of fuel to the combustion chambers.

In conjunction with the pressure regulator, the Reducing Pipe Bushing helps in modulating the pressure within the fuel or oil lines. This ensures that the regulator can function effectively, providing stable pressure regardless of fluctuations in the system.

Lastly, in the oil replenishing system, it ensures that the oil replenishing valve operates efficiently by maintaining a consistent flow of oil. This is important for automated systems that require precise oil levels to function correctly.

Conclusion

Overall, the 3394834 Reducing Pipe Bushing plays a significant role in enhancing the reliability and efficiency of various engine systems by ensuring smooth transitions and secure connections between components. Its application across different Cummins engines underscores its importance in maintaining the performance and reliability of heavy-duty truck systems.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ -

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.