This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

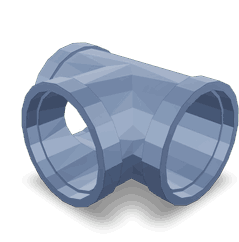

The Cummins 3394876 Female Pipe Tee is a specialized component designed for use in commercial truck systems. Manufactured by Cummins Inc., a leader in the diesel engine and power generation industries, this part is integral to the fluid management systems within heavy-duty vehicles. Its design and functionality are tailored to meet the demanding requirements of commercial trucking, ensuring efficient and reliable operation.

Basic Concepts of Female Pipe Tee

A Female Pipe Tee is a type of fitting used in piping systems to connect three pipes together. It features a T-shaped design with one female thread on the side and two male threads on the ends. This configuration allows for the merging or splitting of fluid flows within a system. In fluid dynamics, such fittings are crucial for directing the flow of liquids or gases, ensuring that systems operate smoothly and efficiently 1.

Purpose of the Cummins 3394876 Female Pipe Tee

The Cummins 3394876 Female Pipe Tee serves a specific role in the operation of commercial trucks by facilitating the distribution or merging of fluid flows. This part is typically used in systems where fluid needs to be directed to multiple locations or combined from different sources. Its application ensures that the fluid management within the truck is both efficient and reliable, contributing to the overall performance of the vehicle 2.

Key Features

The Cummins 3394876 Female Pipe Tee is designed with several key features that enhance its performance and durability. These include a robust material composition that resists corrosion and wear, ensuring longevity in harsh operating conditions. The fitting also features precise connection types that ensure a secure and leak-free seal. Additionally, its design specifications are optimized for easy installation and compatibility with a wide range of system components 3.

Benefits

Using the Cummins 3394876 Female Pipe Tee offers several advantages. It contributes to improved system efficiency by ensuring smooth and reliable fluid flow. The fitting’s design also enhances the reliability of the system, reducing the likelihood of leaks or failures. Furthermore, its ease of installation simplifies maintenance procedures, allowing for quick and efficient replacements or upgrades when necessary.

Installation Considerations

When installing the Cummins 3394876 Female Pipe Tee, it is important to follow guidelines and best practices to ensure proper functionality. This includes ensuring proper alignment of the fitting with the pipes to prevent leaks and ensure efficient fluid flow. Torque specifications should be adhered to during installation to secure the fitting without over-tightening, which could damage the threads. Compatibility with other system components should also be verified to ensure seamless integration.

Troubleshooting and Maintenance

Common issues with the Cummins 3394876 Female Pipe Tee may include leaks, corrosion, or blockages. Diagnostic steps for identifying problems involve inspecting the fitting for signs of wear or damage, checking for proper alignment and torque, and ensuring compatibility with system components. Maintenance tips to ensure longevity and optimal performance include regular inspection for signs of wear, cleaning to remove any buildup, and replacing the fitting if significant corrosion or damage is detected.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable components. The company’s product range includes a variety of engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications 4.

Role of Part 3394876 Female Pipe Tee in Engine Systems

This part is instrumental in the efficient operation of various engine systems by facilitating the distribution and regulation of fluids.

In systems involving valves, the Female Pipe Tee allows for the branching of fluid lines, enabling multiple valves to be supplied from a single source. This setup enhances the system’s flexibility, allowing for precise control over fluid distribution to different parts of the engine. It ensures that each valve receives the necessary fluid pressure and volume, optimizing the engine’s performance and reliability.

When integrated with a pressure regulator, the Female Pipe Tee plays a significant role in maintaining consistent fluid pressure throughout the system. By connecting the regulator to the tee, it ensures that the regulated pressure is evenly distributed to all connected components. This balanced pressure distribution is essential for the stable operation of the engine, preventing issues such as uneven wear or failure of components due to inconsistent fluid pressure.

Conclusion

Overall, the Cummins 3394876 Female Pipe Tee is a key element in enhancing the functionality and efficiency of engine systems by ensuring proper fluid management and distribution. Its robust design, ease of installation, and reliable performance make it an essential component for commercial truck systems.

-

Reif, Konrad. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Reif, Konrad Ed. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing, 2011.

↩ -

Cummins Inc. Service Manual (6318179). X15 CM2350 X139C.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.