This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

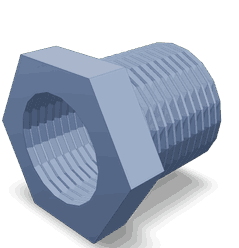

The 3395332 Reducing Pipe Bushing is a component manufactured by Cummins, a well-established name in the commercial truck industry. This part is designed for use in commercial trucks, where it plays a role in the hydraulic or fuel systems by facilitating the connection between pipes of different diameters.

Basic Concepts of Reducing Pipe Bushings

A Reducing Pipe Bushing is a fitting used in fluid systems to connect pipes with different diameters. Its general function is to ensure a smooth transition and flow of fluids from a larger pipe to a smaller one or vice versa. Within a truck’s hydraulic or fuel system, this component helps maintain the integrity of the fluid flow, preventing leaks and ensuring efficient operation 1.

Purpose of the 3395332 Reducing Pipe Bushing

The 3395332 Reducing Pipe Bushing is specifically designed to connect pipes of varying diameters in a truck’s system. It facilitates a seamless transition between these pipes, ensuring that the flow of fluids remains uninterrupted. This part is integral to maintaining the efficiency of the system by allowing for the smooth passage of fluids, whether it be fuel or hydraulic fluid, through the truck’s various systems 2.

Key Features

The 3395332 Reducing Pipe Bushing is constructed from materials that offer durability and resistance to the harsh conditions found in commercial truck environments. Its design specifications are tailored to ensure a snug fit and secure connection between pipes of different sizes. Unique attributes of this bushing include its precision-machined surfaces for a tight seal and its ability to withstand high pressure and temperature variations 3.

Benefits

The advantages of using the 3395332 Reducing Pipe Bushing include improved fluid flow due to its design, which minimizes turbulence and resistance. It also reduces the risk of leaks by providing a secure connection between pipes. Furthermore, this component enhances system efficiency by ensuring a consistent flow of fluids, and its durable construction allows it to perform reliably under demanding conditions.

Installation Considerations

Proper installation of the 3395332 Reducing Pipe Bushing is key to its performance and longevity. Guidelines for installation include adhering to specified torque values to ensure a secure fit without over-tightening, which could damage the bushing or the pipes. Alignment with other system components is also crucial to prevent leaks and ensure efficient fluid flow. Compatibility with the existing system should be verified to avoid any issues with fit or function.

Troubleshooting Common Issues

Common problems with Reducing Pipe Bushings may include leaks or blockages. Troubleshooting steps involve checking the connections for proper alignment and tightness, inspecting the bushing for signs of wear or damage, and ensuring that there are no obstructions in the fluid path. Addressing these issues promptly can help maintain the efficiency and reliability of the truck’s system.

Maintenance Tips

Regular maintenance of the 3395332 Reducing Pipe Bushing is recommended to ensure optimal performance and longevity. This includes periodic inspections for signs of wear, corrosion, or damage, and cleaning the bushing as necessary to remove any buildup that could impede fluid flow. Replacement should be considered if the bushing shows significant wear or if leaks cannot be resolved through tightening or realignment.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality and innovation. The company’s extensive product range and focus on customer satisfaction have established it as a trusted name in the manufacturing of automotive components.

Reducing Pipe Bushing (Part 3395332) Compatibility with Cummins Engines

The Reducing Pipe Bushing, identified by part number 3395332, is a critical component designed to facilitate the connection between different pipe diameters within engine systems. This part is engineered to ensure a secure and leak-free connection, which is essential for maintaining the integrity of the engine’s exhaust and cooling systems.

G8.3 and N14 G Engines

The Reducing Pipe Bushing is compatible with the G8.3 and N14 G engines. These engines, known for their robust design and reliability, benefit from the precise fit and functionality of the bushing. It ensures that the connection between pipes of varying diameters is both efficient and durable, contributing to the overall performance and longevity of the engine.

G855, G855 CM558, and GTA855 CM558 (CM2358) G101

For the G855, G855 CM558, and GTA855 CM558 (CM2358) G101 engines, the Reducing Pipe Bushing is equally important. These engines, which are part of Cummins’ advanced lineup, require high precision components to handle the demands of modern engine technology. The bushing’s design allows for a seamless transition between different pipe sizes, ensuring optimal performance and reducing the risk of leaks or failures.

KTA19GC CM558

The KTA19GC CM558 engine also utilizes the Reducing Pipe Bushing. This engine, known for its power and efficiency, relies on the bushing to maintain the structural integrity of its piping system. The bushing’s compatibility with this engine ensures that the connection points are robust and reliable, supporting the engine’s operational demands.

Role of Part 3395332 Reducing Pipe Bushing in Engine Systems

In the intricate network of an engine system, the 3395332 Reducing Pipe Bushing serves as a pivotal connector, facilitating seamless integration and operation among various components.

Integration with the Module and Fuel Control

The Reducing Pipe Bushing is instrumental in linking the module to the fuel control system. It ensures that the fuel delivery is precise and consistent, which is essential for the module’s efficient operation. This connection allows for optimal fuel metering, directly influencing the engine’s performance and efficiency.

Plumbing and Turbocharger Compatibility

Within the plumbing system, the Reducing Pipe Bushing acts as a transition fitting, accommodating different pipe sizes and ensuring a leak-free connection. When integrated with the turbocharger, it helps maintain the integrity of the exhaust gas recirculation (EGR) system. This ensures that the turbocharger operates within its designed parameters, enhancing overall engine performance and reducing emissions.

Resistor and Corrosion Protection

In systems where resistors are employed to manage electrical flow, the Reducing Pipe Bushing provides a secure connection point. Its design also incorporates features that protect against corrosion, extending the lifespan of both the bushing and the connected components. This is particularly important in environments where exposure to moisture and chemicals is high.

Valve and Pressure Regulator Interaction

The Reducing Pipe Bushing plays a significant role in the operation of valves and pressure regulators. By providing a stable and reliable connection, it ensures that these components can respond accurately to changes in system pressure. This is vital for maintaining consistent engine operation and preventing issues such as fuel starvation or over-pressurization.

Conclusion

In summary, the 3395332 Reducing Pipe Bushing is a versatile and essential component that enhances the functionality and reliability of various Cummins engines. Its design ensures a secure and efficient connection between pipes of different diameters, contributing to the overall performance and durability of the engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.