This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

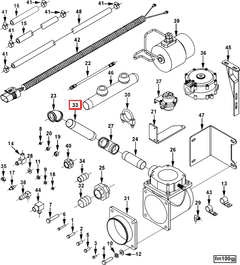

Introduction

The Cummins 3395359 Plain Pipe Nipple is a component designed for use in heavy-duty truck systems. It serves as a connector in various fluid systems, facilitating the transfer of fluids such as fuel, air, and hydraulic fluid. Its role is to provide a secure and reliable connection between different parts of the system, ensuring efficient operation and maintenance of the truck 1.

Basic Concepts of Plain Pipe Nipples

A plain pipe nipple is a short length of pipe with male threads on both ends. It is used to connect two female-threaded components in a fluid system. The primary function of a plain pipe nipple is to extend the connection between these components, allowing for adjustments in the layout of the system. In a truck’s infrastructure, plain pipe nipples are commonly used in fuel lines, air systems, and hydraulic circuits to provide flexibility and ease of assembly 2.

Purpose of the Cummins 3395359 Plain Pipe Nipple

This Cummins part plays a specific role in the operation of a truck by connecting various components within fuel, air, and hydraulic systems. In fuel systems, it helps in the transfer of diesel from the tank to the engine. In air systems, it assists in the distribution of compressed air for brakes and other pneumatic functions. For hydraulic lines, it ensures the proper flow of hydraulic fluid, which is crucial for the operation of various truck mechanisms 3.

Key Features

The 3395359 is constructed from high-quality materials to ensure durability and reliability. It features a specific thread type that is compatible with standard fittings used in heavy-duty trucks. The connection specifications are designed to provide a secure fit, preventing leaks and ensuring the integrity of the fluid system.

Benefits

Using this part offers several advantages. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. The design allows for easy installation, which can save time during maintenance procedures. Additionally, its compatibility with other components ensures that it can be used in a variety of truck systems without the need for additional adapters or modifications.

Installation and Usage

To install the 3395359, first ensure that the components to be connected are clean and free of debris. Use the appropriate tools to screw the nipple into place, ensuring a tight and secure fit. It is important to follow the manufacturer’s guidelines for torque specifications to avoid over-tightening, which can damage the threads, or under-tightening, which can lead to leaks.

Maintenance and Troubleshooting

Regular maintenance of the 3395359 involves checking for signs of wear or corrosion. If leaks are detected, the connections should be re-tightened or the nipple may need to be replaced. Common issues include thread damage or corrosion, which can be addressed by cleaning the threads or replacing the affected components.

Safety Considerations

When working with the 3395359, it is important to follow safety guidelines to prevent accidents. Ensure that the system is depressurized before making any connections or disconnections. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against fluid spills or debris. Additionally, be mindful of the environment to prevent contamination of the fluid system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. The company’s commitment to excellence is reflected in its wide range of products, including the 3395359, which is designed to meet the demanding requirements of heavy-duty applications.

Role of Part 3395359 Plain Pipe Nipple in Engine Systems

The 3395359 is an essential component in the assembly and functionality of various engine systems, particularly when interfacing with the module and fuel control systems.

Integration with the Module

In engine systems, the module often serves as the brain, controlling various operations and ensuring that all components work in harmony. The 3395359 facilitates the connection between different sections of the module, allowing for the transfer of fluids or gases necessary for the module’s operation. This part ensures a secure and leak-free connection, which is vital for maintaining the integrity of the system. Its role is to provide a straightforward yet reliable pathway for the substances to travel, ensuring that the module receives what it needs to function correctly.

Contribution to Fuel Control

The fuel control system is another area where the 3395359 plays a significant role. This system is responsible for regulating the fuel supply to the engine, ensuring that it operates efficiently and within safe parameters. The Plain Pipe Nipple is used to connect various components within the fuel control system, such as filters, regulators, and sensors. By providing a consistent and secure connection, it helps maintain the precise fuel mixture required for optimal engine performance. Additionally, it aids in the monitoring and adjustment of fuel flow, contributing to the overall efficiency and reliability of the fuel control system.

Conclusion

In both the module and fuel control systems, the 3395359 is a fundamental component that ensures the smooth operation and integration of various engine parts. Its ability to provide a secure, leak-free connection is instrumental in maintaining the performance and reliability of these complex systems.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.