This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

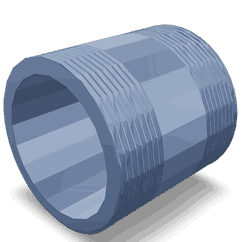

The 3395369 Plain Pipe Nipple, manufactured by Cummins, is a component used in commercial trucks. This part is integral to various fluid transfer systems, ensuring the efficiency and reliability of truck operations 2.

Basic Concepts of Plain Pipe Nipple

A Plain Pipe Nipple is a short pipe segment with male threads on both ends, used to connect two other pipe fittings. It serves as a connector in plumbing and fluid systems, facilitating the transfer of fluids between components. Its design ensures a secure and leak-free connection, which is crucial for the efficient operation of these systems 1.

Purpose of the 3395369 Plain Pipe Nipple in Truck Operations

In commercial trucks, the 3395369 Plain Pipe Nipple is essential for fluid transfer systems. It connects various parts of the system, ensuring smooth and efficient fluid transfer. This part’s role in maintaining the integrity of the fluid transfer system is significant for the overall operation of the truck 2.

Key Features

The 3395369 Plain Pipe Nipple is made from high-quality steel, designed to withstand the rigors of truck operations. Its dimensions are precisely engineered for specific applications, ensuring a snug and secure connection. The design enhances its performance and durability, making it a reliable component in truck fluid systems 2.

Benefits

Using the 3395369 Plain Pipe Nipple offers several advantages. It improves efficiency in fluid systems by providing a secure and leak-free connection. Its design allows for ease of installation, reducing downtime during maintenance. Additionally, its durability ensures long-term reliability, minimizing the need for frequent replacements 2.

Installation Process

Installing the 3395369 Plain Pipe Nipple requires careful attention to detail. The process involves using appropriate tools to ensure a secure fit. It is important to follow manufacturer guidelines to avoid over-tightening, which can damage the threads, or under-tightening, which can lead to leaks. Proper installation is key to the part’s performance and longevity 2.

Maintenance Tips

To ensure the longevity and optimal performance of the 3395369 Plain Pipe Nipple, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage and cleaning to remove any buildup that could affect its function. Adhering to these maintenance practices helps in preserving the integrity of the fluid transfer system 2.

Troubleshooting Common Issues

Common issues with the 3395369 Plain Pipe Nipple may include leaks or corrosion. Addressing these problems promptly is important to maintain system efficiency. Solutions may involve tightening connections, replacing damaged parts, or applying corrosion-resistant coatings, depending on the specific issue encountered 2.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history in the industry, Cummins is known for its wide range of products and its strong reputation in the commercial truck sector. The company’s commitment to quality and innovation is reflected in its products, including the 3395369 Plain Pipe Nipple 2.

Role of Part 3395369 Plain Pipe Nipple in Engine Systems

The 3395369 Plain Pipe Nipple is a fundamental component in various engine systems, facilitating the secure and efficient connection between different parts. In the Aid system, it ensures the proper flow of fluids by connecting the aid pump to the distribution network, which is essential for maintaining system pressure and performance.

Within the Coolant Heater Starting module, the Plain Pipe Nipple plays a significant role in connecting the heater to the coolant system. This connection allows for the circulation of heated coolant, which is vital for reducing engine wear during startup in cold conditions and enhancing overall engine efficiency.

In the context of the Fuel Control system, the Plain Pipe Nipple is used to link the fuel control module to the fuel lines. This ensures a consistent and regulated fuel supply to the engine, which is important for optimal combustion and performance.

For the Pump system, the Plain Pipe Nipple is employed to connect various pump components, ensuring that fluids are transported efficiently throughout the engine. This is particularly important in systems where precise fluid dynamics are required to maintain engine health and performance.

In the Raw Water system, the Plain Pipe Nipple is utilized to connect the raw water pump to the cooling passages. This connection is essential for the effective circulation of cooling water, which helps in dissipating heat and protecting engine components from overheating.

The Auxiliary Cooling system also benefits from the Plain Pipe Nipple, as it connects auxiliary cooling components to the main cooling system. This ensures that additional cooling mechanisms can operate efficiently, providing extra protection for engine components under high-stress conditions 3.

Conclusion

The 3395369 Plain Pipe Nipple is a vital component in the maintenance and operation of commercial truck fluid systems. Its robust design, ease of installation, and durability make it an essential part for ensuring the efficiency and reliability of truck operations. Regular maintenance and prompt troubleshooting of common issues are key to maximizing the performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.