This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

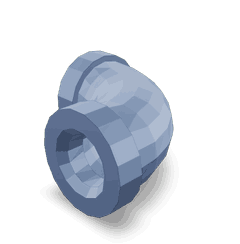

The 3395422 Plain Female Pipe Elbow, manufactured by Cummins, is a critical component in commercial trucks, integral to the fluid systems that are essential for vehicle operation 1.

Basic Concepts of Plain Female Pipe Elbow

A Plain Female Pipe Elbow is a fitting used in fluid systems to change the direction of fluid flow by 90 degrees. It features a female threaded end that connects to male-threaded components, ensuring secure and leak-proof connections. In a truck’s infrastructure, these elbows are vital for routing fluids such as fuel, coolant, or hydraulic fluid through the system without compromising the integrity of the flow 2.

Purpose of the 3395422 Plain Female Pipe Elbow

The 3395422 Plain Female Pipe Elbow serves to redirect fluid flow within a truck’s system. By providing a 90-degree turn, it allows the fluid system to navigate around obstacles or fit within the confined spaces of a truck’s engine compartment. This part contributes to maintaining the system’s integrity by ensuring that fluid paths are direct and efficient, reducing the potential for leaks or system failures 3.

Key Features

The 3395422 Plain Female Pipe Elbow is characterized by several attributes that enhance its performance and durability. It is typically made from high-quality materials that resist corrosion and wear, ensuring longevity in demanding environments. The female threaded connection type allows for a secure fit with corresponding male components, which is crucial for maintaining a sealed system. Its design specifications are tailored to meet the rigorous demands of commercial truck applications, ensuring reliable operation under various conditions.

Benefits

Using the 3395422 Plain Female Pipe Elbow offers several advantages. It improves fluid dynamics by providing a smooth transition in the fluid path, which can enhance system efficiency. The design of the elbow also facilitates ease of installation, allowing for quick and secure connections. Additionally, its robust construction contributes to long-term reliability, reducing the need for frequent replacements or repairs.

Installation Considerations

When installing the 3395422 Plain Female Pipe Elbow, it is important to follow guidelines to ensure proper alignment and a secure fitting. This involves checking for compatibility with the existing system components, ensuring that the threads are clean and undamaged before connection, and using the appropriate tools to achieve a tight seal without over-tightening, which could damage the threads or the fitting itself.

Maintenance and Troubleshooting

Routine maintenance of the 3395422 Plain Female Pipe Elbow involves inspecting the connections for signs of wear or leakage and ensuring that all fittings remain tight. Troubleshooting common issues may involve checking for proper alignment, ensuring that the threads are not damaged, and verifying that the elbow is compatible with the system’s fluid type and pressure ratings. Regular checks can help identify potential problems before they lead to system failures.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s extensive product range and focus on customer satisfaction underscore the reliability and performance of components like the 3395422 Plain Female Pipe Elbow.

Compatibility of Cummins Part 3395422 with Various Engine Models

The Cummins part 3395422, a Plain Female Pipe Elbow, is designed to fit seamlessly with several of Cummins’ engine models. This part is integral for maintaining the structural integrity and functionality of the engine’s exhaust and fluid systems.

G5.9 and G8.3 Engines

The G5.9 and G8.3 engines are part of Cummins’ smaller engine lineup, often used in compact machinery and light-duty applications. The Plain Female Pipe Elbow is used in these engines to connect various exhaust and fluid lines, ensuring a secure and leak-proof connection.

G855 and GTA855 CM558 (CM2358) Engines

Moving to the more powerful G855 and GTA855 CM558 (CM2358) engines, the Plain Female Pipe Elbow plays a crucial role in the complex piping systems of these engines. These engines are typically found in heavy-duty applications, such as construction equipment and large trucks. The part’s robust design ensures it can withstand the high pressures and temperatures encountered in these environments.

G101 and N14 G Engines

The G101 and N14 G engines represent Cummins’ medium-duty engine range. These engines are used in a variety of applications, from medium-duty trucks to industrial machinery. The Plain Female Pipe Elbow is essential in these engines for its ability to connect various components of the engine’s exhaust and cooling systems, ensuring optimal performance and longevity.

Grouping by Application

The Plain Female Pipe Elbow is versatile enough to be used across different engine models, but its application can be grouped based on the engine’s typical use case:

- Light-Duty Engines: G5.9, G8.3

- Heavy-Duty Engines: G855, GTA855 CM558 (CM2358)

- Medium-Duty Engines: G101, N14 G

This grouping helps in understanding the part’s role in different operational contexts, from compact machinery to heavy industrial equipment.

Component Usage of 3395422 Plain Female Pipe Elbow

The 3395422 Plain Female Pipe Elbow is instrumental in the efficient operation of various engine systems. Its primary role is to facilitate the smooth transition of fluid flow within the system, ensuring that components receive the necessary fuel or other fluids without interruption.

In the context of the fuel filter, the Plain Female Pipe Elbow connects the fuel lines to the filter housing. This connection is vital for maintaining the integrity of the fuel delivery system. It allows for the unfiltered fuel to enter the filter, where contaminants are removed, and clean fuel is directed towards the engine.

When integrated with the module, the Plain Female Pipe Elbow often serves as a junction point. This is particularly relevant in fuel injection systems where the module controls the fuel delivery. The elbow ensures that fuel lines are properly aligned and secured, minimizing the risk of leaks and ensuring consistent fuel pressure.

In relation to the fuel control unit, the Plain Female Pipe Elbow plays a significant role in directing fuel from the tank to the control unit. This unit regulates the amount of fuel that is injected into the engine, based on various parameters such as engine load and speed. The elbow’s design allows for a secure and leak-proof connection, which is essential for the precise operation of the fuel control system.

Overall, the Plain Female Pipe Elbow is a fundamental component in ensuring that engine systems operate efficiently and reliably. Its role in connecting and directing fluid flow within these systems cannot be overstated.

Conclusion

The 3395422 Plain Female Pipe Elbow is a vital component in the fluid systems of commercial trucks, ensuring efficient and reliable operation of engine systems. Its design, compatibility with various Cummins engine models, and role in maintaining system integrity make it an indispensable part in the commercial truck industry.

-

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Barton, David C, and John D Fieldhouse. Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier, 2009.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.