This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

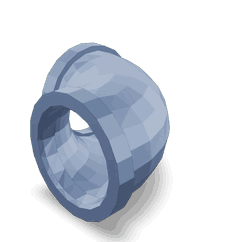

The 3395425 Plain Female Pipe Elbow Fitting is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This fitting is designed for use in commercial trucks, where it plays a role in various fluid systems. Understanding its function and application is key to maintaining the efficiency and reliability of truck operations.

Basic Concepts

A Plain Female Pipe Elbow Fitting is a type of connector used in fluid systems to change the direction of fluid flow. It consists of a female threaded end that connects to a male pipe or fitting, allowing for a 90-degree turn in the system. In the context of a truck’s plumbing or fuel system, this fitting facilitates the routing of fluids such as fuel, coolant, or hydraulic fluid, ensuring that the system operates smoothly and efficiently 4.

Purpose and Role in Truck Operation

This Cummins part serves a specific purpose within a truck’s system by directing fluid flow at a right angle. This is particularly useful in tight spaces or where the layout of the truck’s system requires a change in direction. By maintaining the integrity of the fluid pathway, this fitting contributes to the overall performance and reliability of the truck’s systems 5.

Key Features

The 3395425 Plain Female Pipe Elbow Fitting is characterized by several key features that enhance its functionality and durability. It is typically made from high-quality materials that resist corrosion and wear, ensuring long-term use. The fitting features a precise thread design for a secure connection, and its design specifications are tailored to meet the demands of heavy-duty applications 1.

Benefits

Using the 3395425 Plain Female Pipe Elbow Fitting offers several benefits. It improves fluid management within the truck’s system by providing a reliable means to change the direction of fluid flow. The fitting is designed for ease of installation, which can save time during maintenance or repair work. Additionally, its durable construction ensures long-term reliability, reducing the need for frequent replacements 2.

Installation Considerations

When installing this part, it is important to follow guidelines and best practices to ensure a secure and leak-free connection. This includes using the correct torque specifications to tighten the fitting without over-tightening, which could damage the threads. Proper alignment is also crucial to maintain the integrity of the fluid pathway. Common pitfalls, such as cross-threading or using incompatible fittings, should be avoided to ensure optimal performance 3.

Troubleshooting and Maintenance

To troubleshoot common issues with the 3395425 Plain Female Pipe Elbow Fitting, such as leaks or blockages, it is important to inspect the fitting and its connections regularly. Maintenance practices, such as cleaning the fitting and checking for signs of wear or corrosion, can help ensure longevity and optimal performance. Addressing issues promptly can prevent more significant problems down the line 4.

Compatibility and Applications

The 3395425 Plain Female Pipe Elbow Fitting is designed for use in various truck systems, including fuel, coolant, and hydraulic systems. Its compatibility with other components is an important consideration for ensuring system integrity and performance. Understanding the specific applications and compatibility requirements can help in selecting the appropriate fitting for a given system 5.

Cummins Overview

Cummins is a reputable manufacturer with a long history in the automotive and heavy-duty truck industry. Known for their commitment to quality and innovation, Cummins produces a wide range of components designed to meet the demands of commercial and industrial applications. Their products are recognized for their reliability, performance, and durability, making them a preferred choice for professionals in the field 1.

Cummins Part 3395425: Plain Female Pipe Elbow Fitting in Engine Applications

The Cummins part 3395425, a Plain Female Pipe Elbow Fitting, is a crucial component in the engine systems of various Cummins engines. This fitting is designed to facilitate the connection between different pipes and hoses, ensuring a secure and leak-proof interface.

G8.3 Engines

In the G8.3 engine series, the part 3395425 is utilized in the exhaust system. It connects the exhaust pipe to the muffler, ensuring that the exhaust gases are efficiently channeled and reducing noise levels. This fitting is essential for maintaining the integrity of the exhaust system and ensuring optimal engine performance 2.

KTA19GC CM558 Engines

For the KTA19GC CM558 engines, the part 3395425 is used in the cooling system. It serves as a connection point between the coolant pipes, ensuring that the coolant flows smoothly through the engine. This fitting is critical for maintaining the engine’s temperature within the optimal range, preventing overheating and ensuring efficient operation 3.

Application Across Engine Models

The versatility of the part 3395425 allows it to be used across various engine models within the Cummins lineup. Its design ensures compatibility with different pipe sizes and materials, making it a reliable choice for both original equipment and aftermarket applications. This fitting is engineered to withstand high temperatures and pressures, ensuring durability and longevity in demanding engine environments 4.

Role of Part 3395425 Plain Female Pipe Elbow Fitting in Engine Systems

The Part 3395425 Plain Female Pipe Elbow Fitting is an essential component in various engine systems, facilitating the efficient transfer and regulation of fluids. In the context of a heat exchanger, this fitting allows for the redirection of coolant flow, ensuring optimal heat transfer and maintaining engine temperature within safe operating limits.

Within the fuel control module, the elbow fitting plays a part in the precise delivery of fuel, connecting different segments of the fuel supply lines. This ensures a consistent fuel flow to the engine, which is vital for combustion efficiency and overall engine performance.

In plumbing applications, the fitting is used to change the direction of fluid flow in systems where space constraints or design requirements necessitate a change in pipe orientation. This is particularly important in compact engine designs where every inch of space is optimized.

For the fuel supply system, the elbow fitting is integral in connecting the fuel tank to the fuel lines leading to the engine. It ensures a secure and leak-free connection, which is essential for safety and efficiency.

When integrated with a pressure regulator valve, the fitting aids in maintaining the correct fuel pressure within the system. This is important for the valve’s function in regulating fuel delivery to the engine, ensuring it operates within specified parameters for performance and emissions control 5.

Conclusion

In summary, the Part 3395425 Plain Female Pipe Elbow Fitting is a versatile component that enhances the functionality and reliability of various engine systems by enabling efficient fluid transfer, secure connections, and optimal system performance. Its role in maintaining the integrity of fluid pathways, ensuring secure connections, and facilitating efficient fluid management underscores its importance in the operation and maintenance of commercial trucks and heavy-duty engines.

-

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ ↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ ↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 5677029.

↩ ↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ ↩ ↩ -

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.