This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

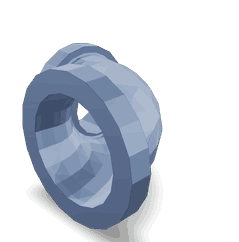

The 3395463 Reducing Female Pipe Elbow is a component manufactured by Cummins, a well-established name in the commercial truck industry. This part is designed for use in commercial trucks, where it facilitates the connection and redirection of fluid flow within various systems.

Basic Concepts of Reducing Female Pipe Elbow

A Reducing Female Pipe Elbow is a fitting used in fluid systems to connect pipes of different diameters at an angle. It allows for a change in direction and size within the piping infrastructure, ensuring smooth and efficient fluid transfer. In the context of a truck’s system, it plays a role in maintaining the integrity and efficiency of fluid pathways 1.

Purpose of the 3395463 Reducing Female Pipe Elbow

The 3395463 Reducing Female Pipe Elbow serves to direct fluid flow between pipes of differing sizes within a truck’s system. It ensures that fluids, whether they be coolants, fuels, or lubricants, are transferred efficiently without leakage or significant pressure loss. This part is integral to the operation of the truck, as it helps maintain the proper function of the fluid systems it is a part of 2.

Key Features

The 3395463 Reducing Female Pipe Elbow is constructed from materials that offer durability and resistance to the corrosive effects of various fluids. Its design includes specific connection types that allow for secure attachment to pipes, and it is engineered to withstand the pressures and temperatures typical in commercial truck applications. These features contribute to its performance and longevity 3.

Benefits

Using the 3395463 Reducing Female Pipe Elbow provides several advantages. It enhances fluid dynamics by ensuring a smooth transition between different pipe sizes, which can improve system efficiency. The design of the elbow also facilitates ease of installation, reducing downtime during maintenance. Furthermore, its robust construction contributes to long-term reliability, minimizing the need for frequent replacements.

Installation Considerations

When installing the 3395463 Reducing Female Pipe Elbow, it is important to follow the manufacturer’s guidelines for torque specifications and alignment. Proper installation ensures that the elbow functions correctly within the system, preventing leaks and maintaining the efficiency of fluid transfer. Attention to detail during this process is key to the part’s optimal performance.

Troubleshooting and Maintenance

Common issues with the 3395463 Reducing Female Pipe Elbow may include leaks or blockages. Regular inspection and maintenance can help identify and address these problems before they lead to system failure. Cleaning the fitting and checking for wear or damage are part of the maintenance practices that can prolong the service life of the elbow.

Compatibility and Applications

The 3395463 Reducing Female Pipe Elbow is typically used in various truck systems where a change in pipe size or direction is required. It is compatible with a range of pipe materials and can be found in applications such as coolant systems, fuel lines, and hydraulic systems.

Safety Considerations

When working with the 3395463 Reducing Female Pipe Elbow, it is important to observe safety practices to prevent accidents. This includes ensuring that the system is depressurized before beginning work, using the appropriate personal protective equipment, and following all manufacturer guidelines to ensure safe operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems that are integral to the performance and reliability of commercial vehicles.

Reducing Female Pipe Elbow (Part 3395463) Compatibility with Cummins Engines

The Reducing Female Pipe Elbow, part number 3395463, manufactured by Cummins, is a versatile component designed to facilitate the connection between pipes of different diameters within engine systems. This part is integral to ensuring smooth fluid flow and maintaining system integrity across various engine configurations.

G8.3 and G855 CM558 Engines

In the G8.3 and G855 CM558 engines, the Reducing Female Pipe Elbow is used to adapt the diameter of the pipes in the exhaust system. This ensures that the exhaust gases transition smoothly from one pipe size to another, minimizing turbulence and optimizing engine performance. The precision engineering of this part ensures it fits seamlessly within the exhaust pathways of these engines.

GTA855 CM558 (CM2358) G101 Engines

For the GTA855 CM558 (CM2358) G101 engines, the Reducing Female Pipe Elbow plays a role in the cooling system. It is used to connect pipes of varying diameters, ensuring that coolant flows efficiently through the engine. This part’s design allows for a secure and leak-proof connection, which is essential for maintaining the engine’s optimal operating temperature and preventing coolant leaks.

Application Across Engine Models

The Reducing Female Pipe Elbow is engineered to be compatible with a range of Cummins engine models, including the G8.3, G855 CM558, and GTA855 CM558 (CM2358) G101. Its design ensures it can be integrated into different parts of the engine system, whether it be the exhaust or cooling systems. This adaptability makes it a valuable component for maintaining the functionality and efficiency of these engines.

Role of Part 3395463 Reducing Female Pipe Elbow in Engine Systems

In engine systems, the part 3395463 Reducing Female Pipe Elbow facilitates the smooth transition and redirection of fluid flow between components of different diameters. This part is integral in maintaining efficient operation across various engine subsystems.

Heat Exchanger Integration

Within the heat exchanger, the Reducing Female Pipe Elbow connects the inlet and outlet pipes, allowing for the efficient transfer of heat between the engine coolant and the surrounding air. This connection ensures that the coolant is properly circulated, aiding in the regulation of engine temperature and enhancing overall thermal management.

Fuel Control Module Connections

In the fuel control module, the Reducing Female Pipe Elbow is used to link the fuel lines that supply and return fuel to and from the engine. This part ensures a seamless transition between pipes of different sizes, minimizing the risk of leaks and maintaining consistent fuel pressure. Its role is vital in the precise delivery of fuel to the engine, contributing to optimal combustion and performance.

Pressure Regulator Assembly

The Reducing Female Pipe Elbow is also employed in the pressure regulator assembly to connect the regulator to the fuel lines. This connection is essential for maintaining the correct fuel pressure within the system, which is necessary for the efficient operation of the engine. By facilitating a smooth transition between components, this part helps prevent pressure drops and ensures stable fuel delivery.

Valve and Module Interconnections

In various valve and module interconnections throughout the engine system, the Reducing Female Pipe Elbow plays a key role in directing fluid flow. Whether connecting the fuel control valve to the fuel lines or linking different modules within the engine, this part ensures that fluids are routed efficiently without unnecessary restrictions or turbulence. This contributes to the reliable operation of the engine and the longevity of its components.

Conclusion

The 3395463 Reducing Female Pipe Elbow is a critical component in the fluid systems of commercial trucks and Cummins engines. Its design and features ensure efficient fluid transfer, ease of installation, and long-term reliability. Proper installation, regular maintenance, and adherence to safety practices are essential for optimal performance and longevity of this part.

-

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ -

Sully, F. K. Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing, 1998.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.