This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

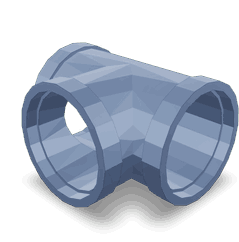

The Cummins 3395481 Female Pipe Tee is a specialized component designed for use in commercial truck operations. Its purpose is to facilitate the distribution of fluids within the truck’s system, ensuring efficient operation and maintenance of various subsystems. The significance of this component lies in its ability to integrate seamlessly into the truck’s fluid management system, contributing to overall system reliability and performance.

Basic Concepts of Female Pipe Tee

A Female Pipe Tee is a type of fitting used in fluid systems to connect three pipes together, allowing for the distribution or merging of fluid flows. It consists of a central body with three openings: one inlet and two outlets, or vice versa. In automotive and industrial settings, Female Pipe Tees are commonly used to manage fluid pathways, ensuring that systems operate smoothly and efficiently. They play a role in directing fluid to multiple destinations or combining flows from different sources 1.

Purpose of the 3395481 Female Pipe Tee in Truck Operations

In the context of commercial trucks, the 3395481 Female Pipe Tee serves a specific function in the fluid distribution network. It allows for the efficient routing of fluids to various components or systems within the truck, such as the engine, transmission, or hydraulic systems. By providing a means to split or merge fluid flows, it contributes to the overall integration and functionality of the truck’s fluid management system 2.

Key Features

The 3395481 Female Pipe Tee is designed with several features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The fitting includes threaded connections that allow for secure attachment to pipes, and its design ensures a tight seal, preventing leaks. Additionally, the tee is engineered to withstand the pressures and temperatures typical of commercial truck operations, making it a reliable component for demanding applications 3.

Benefits

The use of the 3395481 Female Pipe Tee offers several advantages for commercial truck operators. It improves fluid management by providing a reliable means to distribute or combine fluid flows. This can lead to enhanced system reliability, as proper fluid distribution is crucial for the efficient operation of various truck subsystems. Furthermore, by ensuring efficient fluid pathways, the tee can contribute to potential cost savings for fleet operators through reduced maintenance needs and improved system longevity.

Installation Considerations

When installing the 3395481 Female Pipe Tee, it is important to consider compatibility with the existing fluid system. The fitting should be installed using the appropriate tools to ensure a secure and leak-free connection. Step-by-step procedures should be followed to integrate the tee into the system, including proper alignment and tightening of connections. Attention to detail during installation can help prevent issues and ensure the tee functions as intended within the truck’s fluid network.

Troubleshooting and Maintenance

Common issues with the 3395481 Female Pipe Tee may include leaks or blockages, which can affect fluid distribution. Diagnostic methods for identifying problems may involve visual inspection, pressure testing, or fluid analysis. Maintenance tips to ensure long-term performance include regular inspection for signs of wear or corrosion, ensuring connections remain tight, and addressing any issues promptly to prevent further complications. Proper maintenance can help extend the lifespan of the tee and maintain system efficiency.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance and reliability of commercial vehicles. The 3395481 Female Pipe Tee, as a Cummins product, benefits from the company’s commitment to quality and durability, making it a trusted component for commercial truck operators.

Cummins Female Pipe Tee (Part 3395481) Compatibility with Engine Models

The Cummins Female Pipe Tee, identified by part number 3395481, is a versatile component designed to fit seamlessly within various engine configurations. This part is engineered to ensure compatibility and optimal performance across a range of engine models.

G8.3 Engines

The G8.3 engine series benefits from the use of the Female Pipe Tee, as it is integral in managing fluid flow and pressure within the engine’s system. This part is specifically designed to connect pipes in a T-shaped configuration, facilitating efficient routing of fluids and gases. Its application in the G8.3 engines ensures that the system maintains the necessary pressure and flow characteristics, contributing to the engine’s overall performance and longevity.

G855 Engines

Similarly, the G855 engine series incorporates the Female Pipe Tee to enhance its operational efficiency. This part is crucial in the G855 engines for its role in directing and controlling the flow of fluids and gases. The design of the Female Pipe Tee allows for precise and secure connections, which is essential for maintaining the integrity of the engine’s system. By integrating this component, the G855 engines can achieve better performance and reliability, ensuring that the engine operates smoothly under various conditions.

Grouping of Engine Models

The compatibility of the Cummins Female Pipe Tee with both the G8.3 and G855 engines highlights its versatility and importance in engine systems. These engines, while distinct in their specifications and applications, share a common need for efficient fluid and gas management. The Female Pipe Tee’s design and functionality make it an essential component for both engine series, ensuring that they can operate effectively and efficiently.

Role of Part 3395481 Female Pipe Tee in Engine Systems

The 3395481 Female Pipe Tee is an integral component in various engine systems, facilitating the efficient distribution and management of fluids. In the context of the module, this component ensures that the necessary fluids are directed to the appropriate sections without interruption, enhancing the module’s performance and reliability.

Within the fuel control system, the Female Pipe Tee plays a significant role by allowing the precise distribution of fuel to different parts of the engine. This ensures that each component receives the correct amount of fuel, which is essential for optimal combustion and engine efficiency.

In the pump system, particularly the auxiliary pump, the Female Pipe Tee is used to merge or split fluid lines. This capability is vital for maintaining consistent pressure and flow rates, which are necessary for the pump to operate effectively.

For the raw water system, the Female Pipe Tee is employed to manage the flow of cooling water. It ensures that the water is distributed evenly across the engine components that require cooling, thereby preventing overheating and ensuring the longevity of the engine.

Overall, the 3395481 Female Pipe Tee is a versatile component that enhances the functionality and efficiency of various engine systems by enabling the precise management and distribution of fluids.

Conclusion

The 3395481 Female Pipe Tee is a critical component in the fluid management systems of commercial trucks and engines. Its design and features ensure efficient fluid distribution, contributing to the reliability and performance of various subsystems. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this Cummins part, ensuring long-term efficiency and cost savings for operators.

-

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.