This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Injector Fuel Inlet Pipe (Part #3420618) is a component designed for use in the fuel systems of heavy-duty trucks. Its purpose is to facilitate the delivery of fuel from the fuel tank to the injectors, ensuring a consistent and reliable fuel supply. This part is significant within the fuel system as it contributes to the overall efficiency and performance of the engine 1.

Basic Concepts of Injector Fuel Inlet Pipe

The Injector Fuel Inlet Pipe operates on the fundamental principle of providing a pathway for fuel to travel from the fuel tank to the injectors. Within the fuel injection system, this pipe plays a role in maintaining the integrity of the fuel supply line. It ensures that fuel is delivered under the correct pressure and in the right quantity to the injectors, which subsequently atomize the fuel for combustion. This process is integral to achieving optimal engine performance and efficiency 2.

Purpose and Role in Truck Operation

The Injector Fuel Inlet Pipe serves a vital function in the operation of a truck by delivering fuel to the injectors. It ensures that the fuel system maintains its integrity by providing a secure and leak-free connection between the fuel tank and the injectors. This consistent fuel delivery is crucial for the engine’s combustion process, directly influencing the truck’s power output and fuel efficiency.

Key Features

The Cummins Injector Fuel Inlet Pipe is characterized by its robust design and the use of high-quality materials, which contribute to its performance and durability. The pipe is engineered to withstand the high pressures and temperatures within the fuel system. Its design includes features that enhance its resistance to wear and corrosion, ensuring long-term reliability in demanding operating conditions.

Benefits

Utilizing the Cummins Injector Fuel Inlet Pipe offers several benefits. It contributes to improved fuel efficiency by ensuring a consistent and reliable fuel supply to the injectors. This consistent fuel delivery enhances engine performance, allowing for more efficient combustion. Additionally, the pipe’s durable construction and resistance to wear and corrosion increase the reliability of the fuel system, reducing the likelihood of fuel leaks and system failures.

Installation and Compatibility

Proper installation of the Injector Fuel Inlet Pipe is crucial for ensuring its effectiveness and compatibility with the truck’s fuel system. Installation procedures should follow manufacturer guidelines to ensure a secure and leak-free connection. Compatibility with various truck models and fuel systems is achieved through careful design and engineering, ensuring that the pipe meets the specific requirements of each application.

Maintenance and Troubleshooting

Maintaining the Injector Fuel Inlet Pipe is important for ensuring optimal performance and longevity. Regular inspection procedures should be conducted to check for signs of wear, corrosion, or leaks. Common issues to watch for include fuel leaks, which can indicate a compromised seal or connection, and reduced fuel efficiency, which may signal a blockage or restriction within the pipe. Troubleshooting tips for addressing potential problems include checking connections for tightness, inspecting for signs of wear or damage, and ensuring that the pipe is free from obstructions.

Safety Considerations

Safety is a paramount concern when installing, maintaining, and operating the Injector Fuel Inlet Pipe. Proper handling procedures should be followed to prevent accidents or injuries. This includes wearing appropriate personal protective equipment (PPE) and ensuring that the fuel system is depressurized before performing any maintenance or repairs. Precautions should also be taken to prevent fuel spills and ensure that any work on the fuel system is conducted in a well-ventilated area.

Environmental Impact

The use of the Injector Fuel Inlet Pipe contributes to reducing emissions and promoting fuel efficiency in heavy-duty trucks. By ensuring a consistent and reliable fuel supply, the pipe plays a role in optimizing the combustion process, which can lead to lower emissions. Additionally, the pipe’s durable construction and resistance to wear and corrosion help to minimize the need for frequent replacements, reducing waste and the environmental impact associated with manufacturing new components.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a reputation for quality, Cummins is committed to producing reliable and efficient automotive components. The company’s focus on research and development ensures that its products, including the Injector Fuel Inlet Pipe, meet the evolving needs of the industry and contribute to the performance and efficiency of heavy-duty trucks 3.

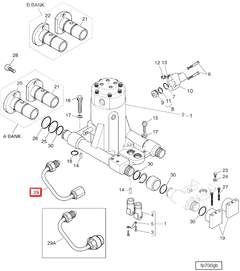

Role of Part 3420618 Injector Fuel Inlet Pipe in Engine Systems

The Injector Fuel Inlet Pipe, identified by part number 3420618, is integral to the efficient operation of fuel assembly plumbing within engine systems. This component facilitates the precise delivery of fuel to the injectors, ensuring optimal performance and reliability of the fuel system.

Integration with Fuel Assembly Plumbing

In the context of fuel assembly plumbing, the Injector Fuel Inlet Pipe serves as a vital conduit. It connects the fuel supply line to the injector, allowing for a consistent and regulated flow of fuel. This ensures that the injectors receive the correct amount of fuel at the right pressure, which is essential for maintaining engine performance and efficiency.

Contribution to Overall Performance

The performance of an engine is heavily influenced by the efficiency of its fuel delivery system. The Injector Fuel Inlet Pipe plays a significant role in this aspect by providing a secure and leak-free connection between the fuel supply and the injectors. This helps in maintaining the desired fuel pressure and flow rate, which are critical for the injectors to atomize the fuel properly. Proper atomization ensures better combustion, leading to improved engine performance and reduced emissions.

Importance in Plumbing and Fuel Systems

Within the broader plumbing and fuel systems of an engine, the Injector Fuel Inlet Pipe is a key component. It works in conjunction with other parts to create a cohesive fuel delivery network. The pipe’s design and material are chosen to withstand the high pressures and temperatures within the fuel system, ensuring durability and reliability over time.

Enhanced Fuel Efficiency

By ensuring a consistent and regulated fuel flow, the Injector Fuel Inlet Pipe contributes to enhanced fuel efficiency. This is particularly important in modern engines where fuel economy is a significant consideration. The pipe’s role in maintaining optimal fuel pressure and flow helps the engine operate more efficiently, reducing fuel consumption and operating costs.

Reliability in High-Performance Engines

In high-performance engine systems, the reliability of the Injector Fuel Inlet Pipe is even more pronounced. These engines demand precise fuel delivery to achieve maximum power output and performance. The pipe’s ability to handle higher pressures and flows without leakage or failure is essential for the sustained performance of high-performance engines.

Conclusion

The Injector Fuel Inlet Pipe, part number 3420618, is a fundamental component in the fuel delivery system of engine systems. Its role in connecting the fuel supply to the injectors, ensuring consistent fuel flow, and contributing to overall engine performance and efficiency cannot be overstated. Engineers and mechanics must understand its importance in maintaining the integrity and performance of the fuel system.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.