This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

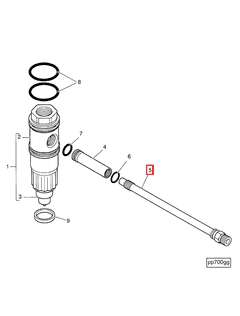

The Injector Fuel Inlet Pipe (Part #3420619) manufactured by Cummins is a critical component in the fuel system of heavy-duty trucks. This part ensures efficient engine performance by facilitating the precise delivery of fuel to the injectors. Its design and functionality are tailored to meet the demanding requirements of heavy-duty applications, contributing to the overall reliability and efficiency of the engine.

Basic Concepts of Injector Fuel Inlet Pipe

The Injector Fuel Inlet Pipe operates on fundamental principles within the fuel injection system. Its primary function is to deliver fuel from the fuel supply system to the injectors. This component ensures that fuel is supplied at the correct pressure and volume, which is vital for the injectors to atomize fuel effectively 3. Proper atomization enhances combustion efficiency, which in turn contributes to overall engine efficiency and performance.

Purpose and Role in Truck Operation

In the context of heavy-duty truck operation, the Injector Fuel Inlet Pipe supports the fuel injection process by maintaining consistent fuel pressure and flow. This consistency is essential for the injectors to operate efficiently, ensuring that the engine receives the precise amount of fuel needed for optimal performance. The pipe’s role in maintaining fuel pressure helps to achieve stable engine operation under varying load conditions 1.

Key Features

The Cummins Injector Fuel Inlet Pipe is designed with several key features that enhance its performance and durability. Constructed from high-quality materials, it is built to withstand the high pressures and temperatures encountered in heavy-duty truck applications. Its design includes precise engineering to ensure a secure fit and reliable seal, minimizing the risk of leaks and ensuring efficient fuel delivery.

Benefits

Using the Cummins Injector Fuel Inlet Pipe offers several benefits. Improved fuel efficiency is one of the primary advantages, as the pipe’s design ensures that fuel is delivered to the injectors with minimal loss or restriction. This efficiency contributes to enhanced engine reliability, reducing the likelihood of fuel-related issues 2. Additionally, the durable construction of the pipe leads to reduced maintenance requirements, providing cost savings over the component’s lifespan.

Troubleshooting and Maintenance

To troubleshoot common issues related to the Injector Fuel Inlet Pipe, it is important to be aware of symptoms such as fuel leaks, inconsistent engine performance, or difficulty starting the engine. Diagnostic procedures may involve inspecting the pipe for signs of wear, corrosion, or damage. Regular maintenance practices, such as checking for leaks and ensuring proper connections, can help prolong the lifespan of the component and ensure optimal performance.

Installation and Compatibility

Proper installation of the Cummins Injector Fuel Inlet Pipe is crucial for its effective operation. Installation procedures should follow manufacturer guidelines to ensure a secure and leak-free connection. Compatibility with various Cummins engine models and other relevant truck systems should be verified to ensure seamless integration and optimal performance.

Performance Enhancements

The use of the Cummins Injector Fuel Inlet Pipe can lead to performance enhancements such as increased fuel economy, reduced emissions, and improved engine responsiveness. These benefits are achieved through the efficient and consistent delivery of fuel to the injectors, which supports more complete and efficient combustion. Real-world applications have demonstrated these advantages, highlighting the component’s contribution to overall truck performance and operational cost savings.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a strong reputation in the automotive industry. The company has a history of innovation and commitment to quality in manufacturing diesel engines and related components. Cummins’ dedication to advancing technology and ensuring the reliability of its products has established it as a leader in the field of heavy-duty truck engines and components.

Role of Part 3420619 Injector Fuel Inlet Pipe in Engine Systems

The Injector Fuel Inlet Pipe, designated as part 3420619, is integral to the efficient operation of various engine components. This component facilitates the precise delivery of fuel to the injector assembly, ensuring optimal performance and reliability.

Integration with Injector Assembly

The Injector Fuel Inlet Pipe is a key element in the injector assembly. It connects the fuel supply line to the injector, allowing for a consistent and regulated flow of fuel. This ensures that the injector receives the correct amount of fuel at the right pressure, which is essential for the injector to atomize the fuel properly. Effective atomization leads to better combustion efficiency and reduced emissions 3.

Interaction with Individual Injectors

Each injector within the assembly relies on the Injector Fuel Inlet Pipe to maintain a steady fuel supply. The pipe’s design minimizes fuel line restrictions, which helps in maintaining consistent fuel pressure across all injectors. This uniformity is vital for balanced engine performance, as it ensures that each cylinder receives an equal amount of fuel, promoting smooth operation and power delivery.

Contribution to Overall Performance

The role of the Injector Fuel Inlet Pipe extends beyond individual components to influence the overall performance of the engine. By ensuring a reliable fuel supply, it supports the engine’s ability to meet performance demands under various operating conditions. Whether the engine is idling, cruising, or under full load, the consistent fuel delivery provided by the Inlet Pipe helps maintain engine stability and responsiveness.

Importance in Parts Maintenance

When considering parts maintenance, the Injector Fuel Inlet Pipe plays a significant role. Regular inspection and maintenance of this component can prevent fuel delivery issues that might otherwise lead to decreased engine efficiency or failure. Ensuring the Inlet Pipe is free from clogs and leaks is essential for the longevity and reliability of the injector assembly and the engine as a whole.

Conclusion

The Injector Fuel Inlet Pipe (part 3420619) is a fundamental component that supports the intricate dance of fuel delivery within engine systems. Its reliable performance is a cornerstone of efficient combustion and overall engine health. Regular maintenance and proper installation are essential to ensure the longevity and efficiency of this critical component.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng, Automotive Heating Ventilation and Air Conditioning, Jones Bartlett Learning, 2018.

↩ -

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Springer Vieweg, 2007.

↩ -

John C Dixon, Tyres Suspension and Handling Second Edition, SAE International, 1996.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.