This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3422697 Pipe Connector is a component designed for use in commercial trucks. It serves a specific function within the truck’s fluid systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is key to maintaining and optimizing the performance of commercial trucks.

Basic Concepts of Pipe Connectors

Pipe connectors are components used in fluid systems to join pipes and other elements, facilitating the transfer of liquids or gases. They ensure a secure and leak-free connection, which is vital for the proper operation of various systems within a vehicle. In the context of commercial trucks, these connectors play a role in maintaining the integrity and efficiency of fluid transfer processes 1.

Purpose of the 3422697 Pipe Connector

The 3422697 Pipe Connector is designed to connect different sections of the fluid system in a truck. Its role involves ensuring a secure and efficient transfer of fluids, which is important for the operation of the truck’s systems. By providing a reliable connection point, it helps maintain the overall functionality and performance of the truck 2.

Key Features

The 3422697 Pipe Connector is constructed from durable materials, ensuring it can withstand the pressures and conditions within a truck’s fluid system. Its design includes features that enhance its performance and durability, such as precise fitting mechanisms and corrosion-resistant properties. These characteristics contribute to its reliability and longevity in demanding applications 3.

Benefits

The use of the 3422697 Pipe Connector offers several benefits. It provides improved efficiency in fluid transfer, enhances the reliability of the connections within the system, and is designed for ease of installation. Compared to other similar components, it offers a combination of performance, durability, and simplicity in application, which are valuable attributes in the maintenance and operation of commercial trucks 4.

Installation Process

Installing the 3422697 Pipe Connector involves several steps to ensure a secure and effective fit. The process requires specific tools and may involve additional components to complete the connection. Following best practices during installation is important to achieve a leak-free and durable connection, contributing to the overall efficiency and safety of the truck’s fluid systems 5.

Maintenance Tips

Regular maintenance of the 3422697 Pipe Connector is important to ensure its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, and following recommended maintenance schedules. Proper care and attention to this component can help prevent issues such as leaks or reduced efficiency in the fluid system 6.

Troubleshooting Common Issues

Common problems associated with pipe connectors, such as leaks or corrosion, can often be addressed through systematic troubleshooting. Identifying the source of the issue and applying the appropriate corrective measures is important to maintain the integrity and efficiency of the truck’s fluid systems. Regular inspections and maintenance can help prevent many of these issues from occurring 7.

Compatibility and Applications

The 3422697 Pipe Connector is designed for use in specific types of trucks and fluid systems. It is important to ensure compatibility with the truck’s model and application to achieve the best performance and reliability. Understanding its intended use and applications helps in selecting the right component for the job 8.

Safety Considerations

When working with the 3422697 Pipe Connector, observing safety practices and precautions is important. This includes proper handling procedures and being aware of potential hazards associated with fluid systems. Adhering to safety guidelines helps protect individuals and ensures the safe and effective operation of the truck 9.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. With a history of innovation and commitment to excellence, Cummins continues to be a leading provider of components and solutions for the commercial vehicle sector.

Cummins Pipe Connector 3422697 Compatibility with Engine Models

The Cummins Pipe Connector part number 3422697 is designed to integrate seamlessly with several engine models, ensuring efficient fluid transfer and system integrity. This part is compatible with the following engine models:

- QSV81G

- QSV91-G4 CM558/CM700 V102

- QSV91G

For the QSV81G and QSV91G engines, the Pipe Connector 3422697 is engineered to fit precisely, facilitating smooth operation and reducing the risk of leaks. Its robust construction ensures it can withstand the rigors of continuous use in demanding environments.

In the case of the QSV91-G4 CM558/CM700 V102 engine, the Pipe Connector 3422697 is specifically tailored to meet the unique requirements of this model. Its design allows for optimal fluid dynamics, enhancing overall engine performance and longevity.

When installing this connector, it is crucial to ensure that it is properly aligned and securely fastened to prevent any potential issues. This part is a critical component in maintaining the efficiency and reliability of the engines it supports.

Role of Part 3422697 Pipe Connector in Engine Systems

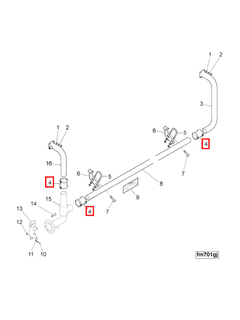

The Part 3422697 Pipe Connector is an essential component in the integration and operation of various engine systems. It facilitates the secure and efficient connection between gas pipes and multiple modules within the engine assembly.

Integration with Gas Pipes and Assemblies

In engine systems, the Pipe Connector ensures a reliable link between gas pipes and the assembly (assy). This connection is vital for the consistent flow of gas, which is necessary for the engine’s performance. The secure fitting provided by the connector prevents leaks and ensures that the gas supply remains uninterrupted.

Connection to Gas Modules

The Pipe Connector plays a significant role in interfacing with different gas modules, such as the Gas Module P=1,25bar, Gas Module P=1,8bar, and Gas Module P=3bar. Each of these modules operates at specific pressure levels, and the connector must be compatible with these pressures to maintain system integrity. It allows for the precise regulation of gas flow into the engine, which is essential for optimal combustion and efficiency.

Fuel Control Module Interaction

Furthermore, the Pipe Connector is integral to the Fuel Control Module. This module relies on a steady and controlled gas supply to function correctly. The connector ensures that the gas reaches the Fuel Control Module without fluctuations in pressure or flow, which could otherwise lead to inefficient fuel management and potentially harmful engine operations.

Assembly with Gas Module Components

The connector also facilitates the assembly of the Gas Module and Module Assembly Gas. These components are designed to work in unison to deliver gas to the engine at the required pressure and volume. The Pipe Connector’s role in this assembly is to provide a stable and leak-proof connection, which is paramount for the safe and effective operation of the engine system.

In summary, the Part 3422697 Pipe Connector is a key component in the engine’s gas delivery system. It ensures that all connections between gas pipes and modules are secure, which is fundamental for the engine’s reliable and efficient operation.

Conclusion

The Cummins 3422697 Pipe Connector is a vital component in the fluid systems of commercial trucks, ensuring secure and efficient fluid transfer. Its durable construction, ease of installation, and compatibility with specific engine models make it a reliable choice for maintaining the performance and reliability of commercial vehicles. Regular maintenance and proper installation practices are essential to maximize the benefits of this component.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Crolla, D. (2015). Crolla Encyclopedia. Wiley.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659707.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659707.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659707.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659707.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659707.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659707.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.