This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

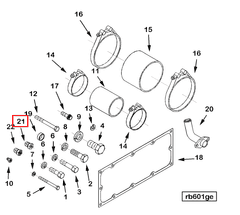

The 3628002 Reducing Pipe Bushing, manufactured by Cummins, is a critical component in the operation of commercial trucks, particularly within fluid systems that require precise connections and efficient fluid transfer 1.

Basic Concepts of Reducing Pipe Bushings

A reducing pipe bushing is a fitting used in fluid systems to connect pipes of different diameters. Its primary function is to facilitate the transition between larger and smaller pipes, ensuring a smooth and uninterrupted flow of fluids. In the context of a truck’s hydraulic or fuel system, the reducing pipe bushing allows different sections of the system to connect seamlessly, regardless of their varying diameters 2.

Purpose of the 3628002 Reducing Pipe Bushing

The 3628002 Reducing Pipe Bushing is designed to connect pipes of different diameters within a truck’s system, ensuring a smooth transfer of fluids. It facilitates the transition between larger and smaller pipes, which is essential for maintaining the efficiency and reliability of the truck’s fluid systems. By providing a secure and leak-free connection, it contributes to the overall performance of the vehicle 3.

Key Features

This Cummins part is constructed from high-quality materials, ensuring durability and resistance to wear and corrosion. Its design specifications include precise dimensions to ensure a snug fit within the connected pipes. Additionally, it features a robust construction that enhances its performance under various operating conditions 4.

Benefits

The 3628002 Reducing Pipe Bushing offers several advantages. It improves fluid flow by providing a smooth transition between pipes of different diameters, which helps in maintaining system efficiency. It also reduces the risk of leaks, ensuring that the fluid systems operate reliably. Furthermore, its durable construction contributes to the longevity of the component, offering cost-effective performance over time 5.

Installation Process

Installing the 3628002 Reducing Pipe Bushing involves several steps to ensure a secure fit. First, the connecting pipes should be cleaned and inspected for any damage. The bushing is then positioned between the pipes, ensuring that it aligns correctly with both ends. Tools such as wrenches may be required to tighten the connections securely. It is important to follow the manufacturer’s guidelines to ensure proper installation 6.

Troubleshooting Common Issues

Common issues with reducing pipe bushings include leaks and blockages. To troubleshoot these problems, inspect the connections for any signs of wear or damage. Ensure that the bushing is correctly aligned and securely fastened. If a leak is detected, it may be necessary to replace the bushing or the connecting pipes. Regular maintenance can help prevent these issues 7.

Maintenance Tips

To prolong the lifespan of the 3628002 Reducing Pipe Bushing, regular maintenance is recommended. This includes periodic inspections to check for signs of wear or damage. Cleaning the bushing and the connecting pipes can help prevent blockages and ensure smooth fluid flow. If any issues are detected, it is advisable to address them promptly to avoid more significant problems 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. Their product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles 9.

Cummins Reducing Pipe Bushing 3628002 Compatibility

The Cummins Reducing Pipe Bushing, part number 3628002, is designed to fit seamlessly with a range of Cummins engines, ensuring a precise and reliable connection between different pipe diameters. This bushing is essential for maintaining the integrity of the exhaust system and ensuring optimal engine performance.

K38 Engines

For the K38 engine series, the 3628002 bushing is engineered to interface with specific exhaust system components. Its design allows for a smooth transition between pipes of varying diameters, reducing stress and wear on the system. This bushing is vital for maintaining the alignment and stability of the exhaust components, which is crucial for the engine’s overall efficiency and longevity.

K50 Engines

Similarly, in the K50 engine series, the 3628002 bushing plays a crucial role in the exhaust system. It ensures that the connection between pipes of different sizes is both secure and leak-free. This bushing is particularly important in high-performance applications where exhaust pressure and temperature can be extreme. The precise fit and durability of the 3628002 bushing help to maintain the structural integrity of the exhaust system, contributing to the engine’s reliability and performance.

Grouping for Efficiency

When considering the use of the 3628002 bushing across different engine models, it is important to note that its design is optimized for compatibility with both the K38 and K50 engine series. This allows for a standardized approach to maintenance and repair, simplifying the process for technicians and reducing the need for multiple part inventories. The bushing’s consistent performance across these engines ensures that it can be used interchangeably, providing a cost-effective and efficient solution for exhaust system maintenance 10.

Role of Part 3628002 Reducing Pipe Bushing in Engine Systems

In the orchestration of engine systems, the 3628002 Reducing Pipe Bushing assumes a significant role by ensuring seamless fluid dynamics and structural integrity. This component is integral in the assembly where the subbase interfaces with various engine components.

Integration with Subbase

The subbase serves as the foundational platform for the engine, providing a stable surface for mounting and alignment of other components. The 3628002 Reducing Pipe Bushing is positioned within this subbase to facilitate the transition between different pipe diameters, optimizing the flow of fluids or gases. Its precise fit within the subbase ensures that there are no leaks or disruptions in the flow, which is essential for the efficient operation of the engine 11.

Subbase Mounting

When it comes to subbase mounting, the 3628002 Reducing Pipe Bushing plays a supportive role. It is often situated at junctures where pipes of varying sizes need to be connected securely. The bushing’s design allows for a snug fit, which is vital when the subbase is being mounted to the engine frame or other supporting structures. This secure connection is paramount to maintaining the alignment and stability of the engine components during operation 12.

Subbase Mounting Kit

In scenarios where a subbase mounting kit is employed, the 3628002 Reducing Pipe Bushing is a complementary piece. The mounting kit typically includes brackets, fasteners, and possibly additional bushings or spacers. The reducing pipe bushing ensures that all components within the kit are properly aligned and that the transition between different pipe sizes is smooth. This is particularly important in high-pressure or high-temperature environments where even minor misalignments can lead to significant issues 13.

Conclusion

The 3628002 Reducing Pipe Bushing is a specialized component that enhances the functionality and reliability of engine systems by ensuring proper fluid dynamics and structural stability in conjunction with the subbase, subbase mounting, and subbase mounting kit. Regular maintenance and proper installation are key to maximizing the performance and lifespan of this critical component.

-

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Richards, Paul, and Jim Barker. Automotive Fuels Reference Book. SAE International, 2023.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5579751, 2023.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Richards, Paul, and Jim Barker. Automotive Fuels Reference Book. SAE International, 2023.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5579751, 2023.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5579751, 2023.

↩ -

Richards, Paul, and Jim Barker. Automotive Fuels Reference Book. SAE International, 2023.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5579751, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.